Surface layer coating agent coating device for wicker basket weaving wickers

A coating device and coating agent technology, which is applied in the directions of coating, coating dipping, wood processing appliances, etc., can solve the waste of related coating agents, affect the efficiency of work, increase working time and other problems, and achieve increased efficiency, Improve quality and increase the effect of mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

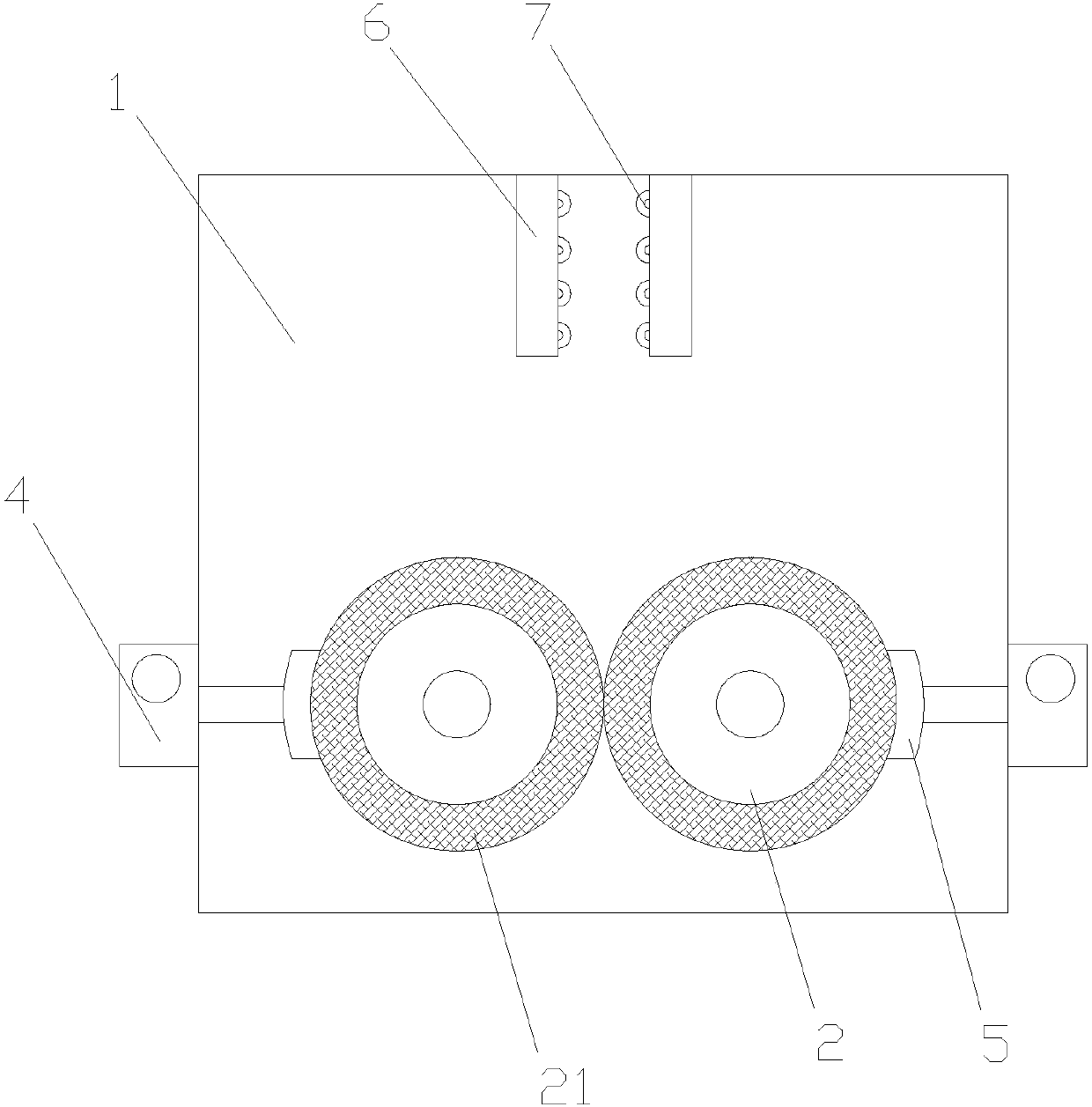

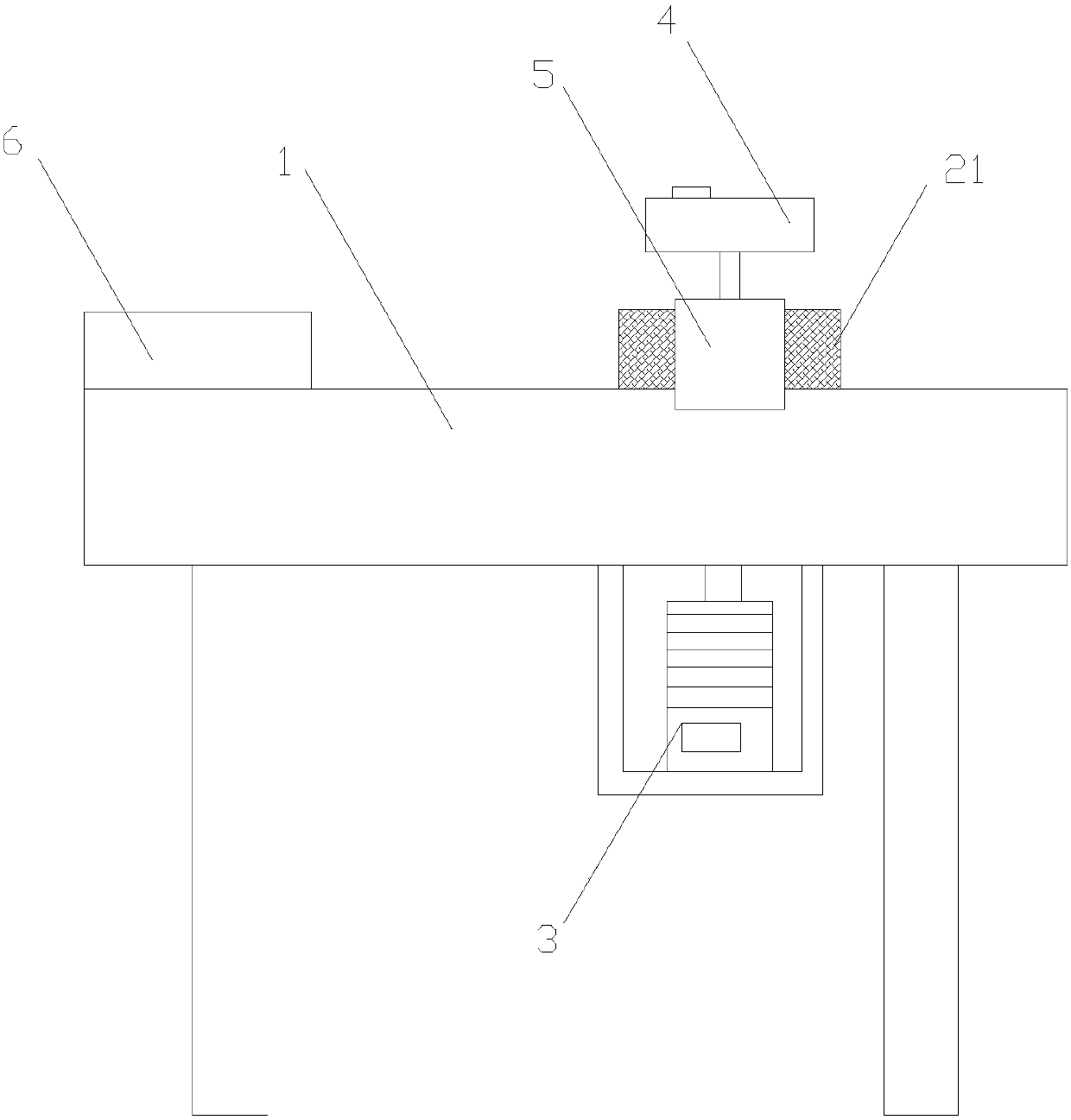

[0038] Embodiment 1: as Figure 1-Figure 2 Shown:

[0039]The surface coating agent coating device for weaving wicker in wicker baskets includes a conveying table 1, a conveying wheel 2, a coating cover 21, a drive motor 3, a medicine bucket 4 and a guide frame 6, wherein two conveying wheels 2 are provided, The delivery wheels 2 are all installed in the middle of the delivery platform 1, and a coating cover 21 is installed outside the delivery wheel 2. The coating cover 21 is a sponge structure, and the coating cover 21 and the delivery wheel 2 are fixedly combined. A coating agent injection pipe 5 is installed on the outside of the coating sleeve 21, and the coating agent injection pipe 5 is connected to the drug bucket 4 through a pipeline. There is a driving motor 3, and the driving motor 3 is fixedly installed on the bottom of the conveying platform 1, and a guide frame 6 is installed on the front end of the conveying platform 1;

[0040] The front end of the coating ag...

Embodiment 2

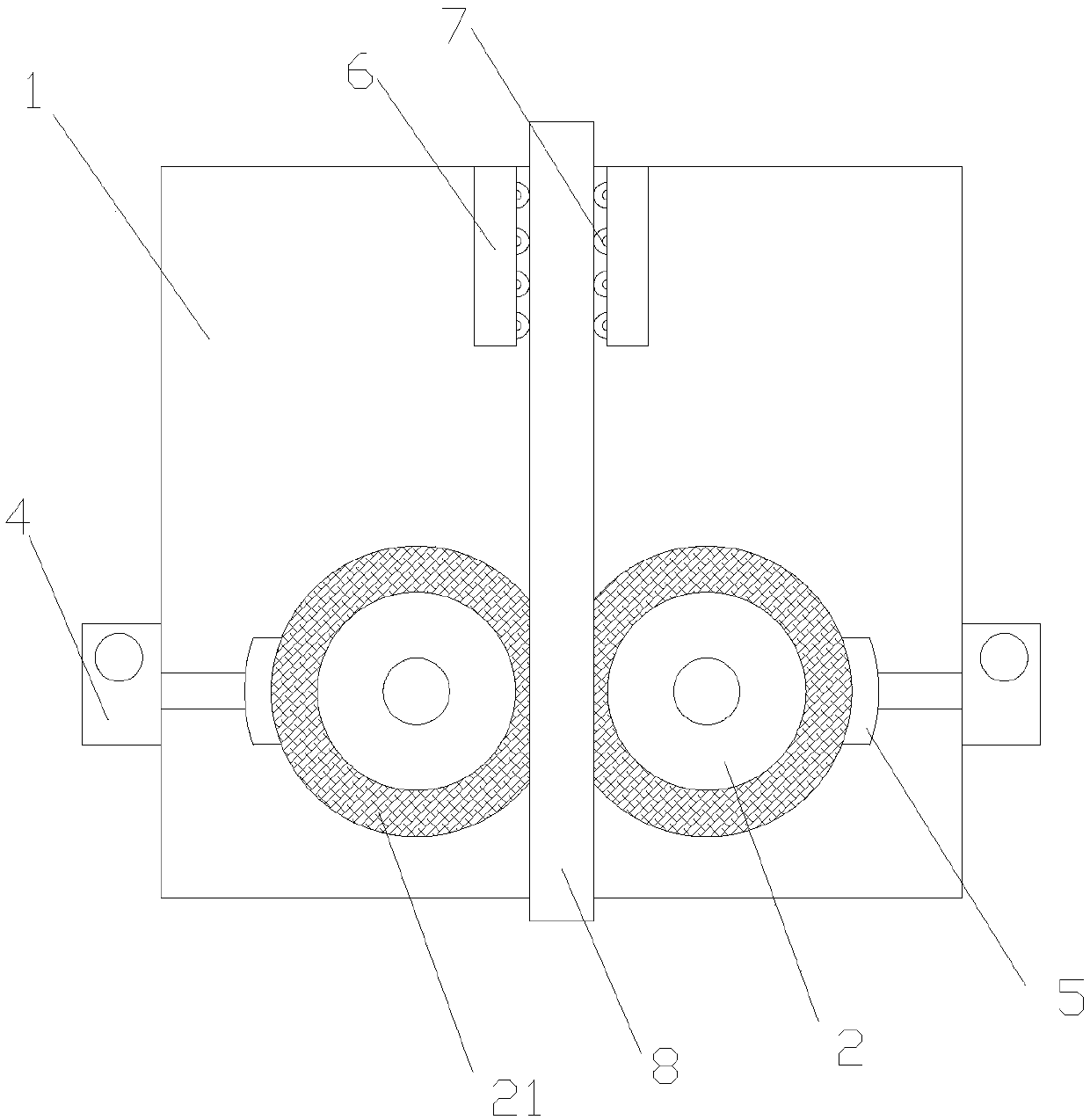

[0046] Embodiment 2: as image 3 As shown, the surface coating agent coating device for wicker basket weaving wicker conveys wicker from the guide frame 6 during use, and then the wicker passes between the two conveying wheels 2, and is conveyed by the drive motor 3 pairs The driving of the wheel 2 can make the delivery wheel 2 transport the wicker, and at the same time, the coating sleeve 21 installed on the outside of the delivery wheel 2 can coat the surface of the wicker after absorbing the coating agent flowing in from the medicine bucket 4. Coating, when the wicker is extruding the coating sleeve 21, the coating agent will adhere to the surfaces of the two sides of the wicker, and then when a wicker is coated, the wicker is rotated and then the other two sides are coated, so that It can ensure that every side around the wicker can be coated, and this dipping coating will not waste the coating agent and will make the coating more uniform.

Embodiment 3

[0048] The coating agent in the surface coating agent coating device for wicker basket weaving wicker is prepared from the following components: 11 parts of propolis, 7 parts of copper cyanide, 5 parts of coal tar, 9 parts of vinyl acetate, maple grass oil 0.8 parts, 0.4 parts of cinnamon oil, 4 parts of ethanol, 0.8 parts of potassium persulfate, 0.6 parts of diesel oil, 5 parts of calixarene, 1.3 parts of sodium alginate, 45 parts of deionized water, 2.5 parts of montmorillonite, 0.6 parts of polyvinyl ammonium acetate 4 parts of inorganic salt copper sulfate, 2 parts of toilet water, 1 part of sodium fluoride, 0.2 parts of starch glue, 25 parts of protective additives;

[0049] Wherein the protective additive is made from the following raw materials in parts by weight: 1.5 parts of D-mannuronic acid pentasaccharide, 7 parts of mineral salt, 3 parts of phthalic anhydride, 1.5 parts of polyvinyl alcohol, 2.5 parts of propylene glycol butyl ether, borax 0.8 parts of sodium ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com