Content-removed rubber wood powder/high-density polyethylene composite material and preparation method thereof

A high-density polyethylene and composite material technology, used in wood processing tools, manufacturing tools, etc., can solve the problems of being susceptible to fungi and insects, high carbohydrate content, and reduced service life, and achieve market competitiveness enhancement, Improve mildew resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

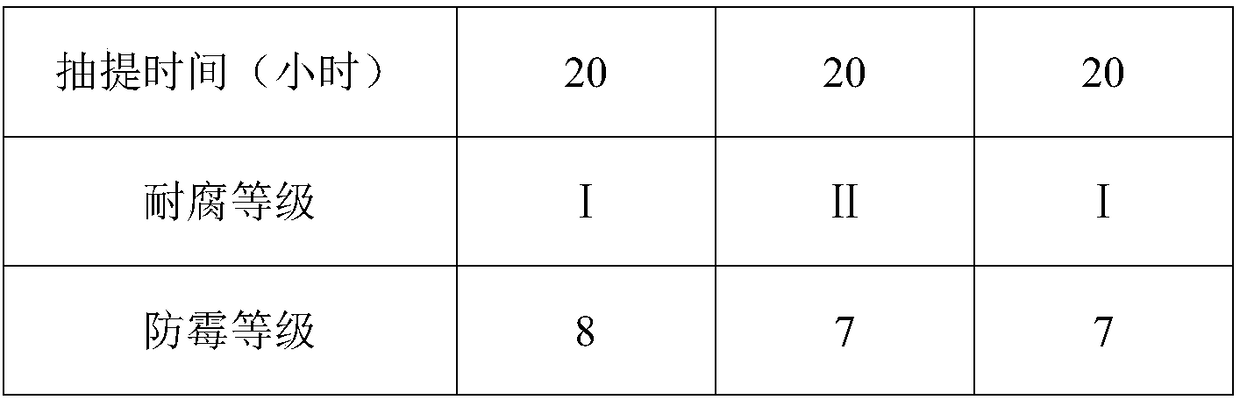

Embodiment 1

[0032] (1) Rubber wood powder pretreatment: choose rubber wood powder with a mesh number of 60, dry the wood powder at 103°C, and use deionized water as the extraction solvent to extract the rubber wood powder by Soxhlet extraction for 20 hours, the extraction temperature is 100°C, and after the extraction is completed, dry to a moisture content of 2-5% for later use;

[0033] (2) Mixed material: Add 60 parts of dried rubber wood powder and 40 parts of HDPE plastic by weight into a high-speed mixer with a rotation speed of 400r / min for mixing. After mixing evenly, add by weight 22 parts of processing aids (5 parts of zinc stearate, 10 parts of dioctyl terephthalate (DOTP), 7 parts of coupling agent maleic anhydride grafted polyethylene (MAPE), then mixed for 10 min, and the mixing temperature was 50°C, after mixing evenly, let the material stand to room temperature.

[0034] (3) Extrusion molding: the uniformly mixed material is granulated with a granulator, and then the pell...

Embodiment 2

[0036] (1) Rubber wood powder pretreatment: choose rubber wood powder with a mesh number of 100 mesh, dry the wood powder at 103°C, and use methanol as the extraction solvent to extract the rubber wood powder for 20 hours by Soxhlet extraction , the extraction temperature is 65°C, and after the extraction is completed, it is dried to a moisture content of 2-5% for later use;

[0037] (2) Mixed material: Add 50 parts of dried rubber wood powder and 50 parts of HDPE plastic by weight into a high-speed mixer with a speed of 400r / min for uniform mixing, and then add by weight for processing Auxiliaries (4 parts of zinc stearate, 10 parts of dioctyl terephthalate (DOTP), 5 parts of coupling agent maleic anhydride grafted polyethylene (MAPE), and then mixed for 10 minutes, the mixing temperature was 50 ° C, After mixing evenly, let the material stand to room temperature.

[0038] (3) Extrusion molding: the uniformly mixed material is granulated with a granulator, and then the pelle...

Embodiment 3

[0040] (1) Pretreatment of rubber wood powder: choose rubber wood powder with a mesh number of 80, dry the wood powder at 103°C, and use benzene-ethanol as the extraction solvent to extract the rubber wood powder by Soxhlet extraction for 20 hours, the extraction temperature is 69°C, and after the extraction is completed, dry to a moisture content of 2 to 5% for later use;

[0041] (2) Mixed material: 40 parts of dried rubber wood powder and 60 parts of HDPE plastics are measured according to the formula and added to a high-speed mixer with a speed of 400r / min for mixing. After mixing evenly, add by weight Processing aid (3 parts of zinc stearate, 10 parts of dioctyl phthalate (DOTP), 3 parts of coupling agent maleic anhydride grafted polyethylene (MAPE)), then mixed for 10 min, the mixing temperature was 50°C, after mixing evenly, let the material stand to room temperature.

[0042] (3) Extrusion molding: the uniformly mixed material is granulated with a granulator, and then t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com