Method for improving nickel slag grinding efficiency and activity

A nickel slag powder and efficiency technology, which is applied in the field of improving the efficiency and activity of nickel slag grinding, can solve the problem of affecting the grinding efficiency and particle gradation of nickel slag powder, increasing energy consumption and production cost of nickel slag grinding, and hindering nickel slag grinding. Grinding and other problems, to achieve significant economic and social benefits, solve the effect of ball wrapping and agglomeration, and reduce the power consumption of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Component Weight percent

[0016] Nickel slag 96%

[0017] Limestone 4%

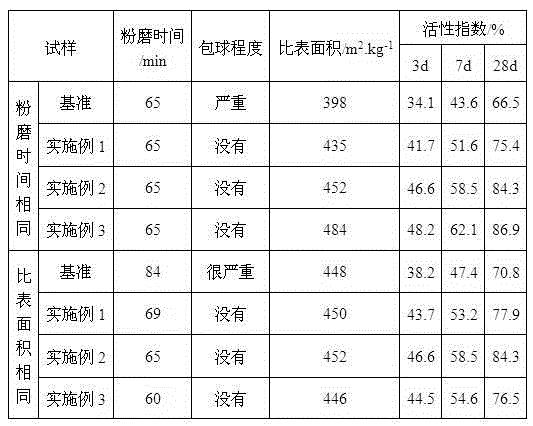

[0018] Put the above materials into a ball mill, and after mixing for a certain period of time, observe the degree of encapsulation, and measure the specific surface area and activity index of the nickel slag powder. The results are shown in Table 1.

Embodiment 2

[0020] Nickel slag 94%

[0021] Limestone 6%

[0022] Put the above materials into a ball mill, and after mixing for a certain period of time, observe the degree of encapsulation, and measure the specific surface area and activity index of the nickel slag powder. The results are shown in Table 1.

Embodiment 3

[0024] Nickel slag 92%

[0025] Limestone 8%

[0026] Put the above materials into a ball mill, and after mixing for a certain period of time, observe the degree of encapsulation, and measure the specific surface area and activity index of the nickel slag powder. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com