Manganese oxide diatomite composite adsorbent for treating lead-containing wastewater and preparation method thereof

A manganese oxide diatomite, composite adsorption technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of decreased adsorption efficiency, difficult diffusion of reaction medium, and easy to reduce the use effect. , to achieve the effect of solving the phenomenon of agglomeration and solving the difficulty of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Disperse 20 g of diatomaceous earth into 100 ml of glucose solution with a mass concentration of 5%, stir for 30 minutes, then filter, dry the obtained solid in an oven at 120°C for 5 hours, and place it in a nitrogen atmosphere furnace, Calcined at 600°C for 2 hours;

[0026] (2) Add the calcined product to a potassium permanganate solution with a concentration of 60 g / L and heat it with microwave for 15 minutes. The amount of the calcined product added is 35 g / L potassium permanganate solution, and the microwave power is controlled at 1kW;

[0027] (3) The product after microwave heat treatment is collected by filtration, washed and dried to obtain a manganese oxide diatomite composite adsorbent whose composition is 5% manganese oxide and 95% diatomite by mass percentage.

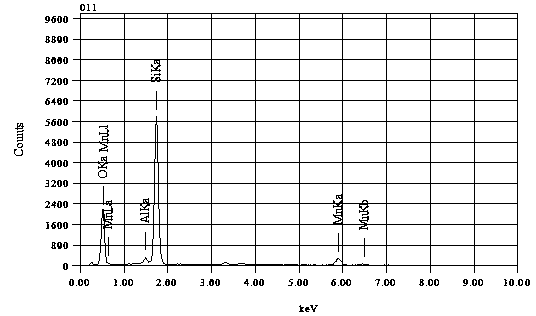

[0028] The low-magnification and high-magnification scanning electron microscope morphologies are as follows: figure 1 with figure 2 As shown, it can be seen that the oxides are evenly dist...

Embodiment 2

[0031] (1) Disperse 25g of diatomaceous earth into 100ml of soluble starch solution with a mass concentration of 2%, stir for 5 minutes, then filter, dry the obtained solid in an oven at 120°C for 5 hours, place it in a vacuum oven, and Calcined at 400°C for 5 hours;

[0032] (2) Add the calcined product to a potassium permanganate solution with a concentration of 100 g / L and heat it with microwave for 5 minutes. The amount of the calcined product added is 10 g / L potassium permanganate solution, and the microwave power is controlled at 4k W;

[0033] (3) The product after microwave heat treatment is collected by filtration, washed and dried to obtain a manganese oxide diatomite composite adsorbent whose composition is 20% manganese oxide and 80% diatomite by mass percentage.

[0034]Put the manganese oxide diatomite composite adsorbent prepared in this example into the lead ion solution with an initial concentration of 80 mg / L at a dosage of 1.5 g / L, and the adsorption kinetic...

Embodiment 3

[0036] (1) Disperse 30g of diatomaceous earth into 100ml of sucrose solution with a mass concentration of 10%, stir for 2 hours, then filter, dry the obtained solid in an oven at 120°C for 5 hours, place it in a nitrogen atmosphere furnace, and Calcined at 800°C for 30 minutes;

[0037] (2) Add the calcined product to a potassium permanganate solution with a concentration of 50 g / L and heat it with microwave for 60 minutes. The amount of the calcined product added is 75 g / L potassium permanganate solution, and the microwave power is controlled at 500 W;

[0038] (3) The product after microwave heat treatment is collected by filtration, washed and dried to obtain a manganese oxide diatomite composite adsorbent whose composition is 40% manganese oxide and 60% diatomite by mass percentage.

[0039] Put the manganese oxide diatomite composite adsorbent prepared in this example into lead ion solutions with different initial concentrations at a dosage of 1 g / L, and its adsorption is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com