Environment-friendly cement technological additive

An admixture and environment-friendly technology, applied in the field of environment-friendly cement process admixtures, can solve problems such as inconvenience and achieve the effects of saving power consumption, good chrome removal effect and good grinding aid effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

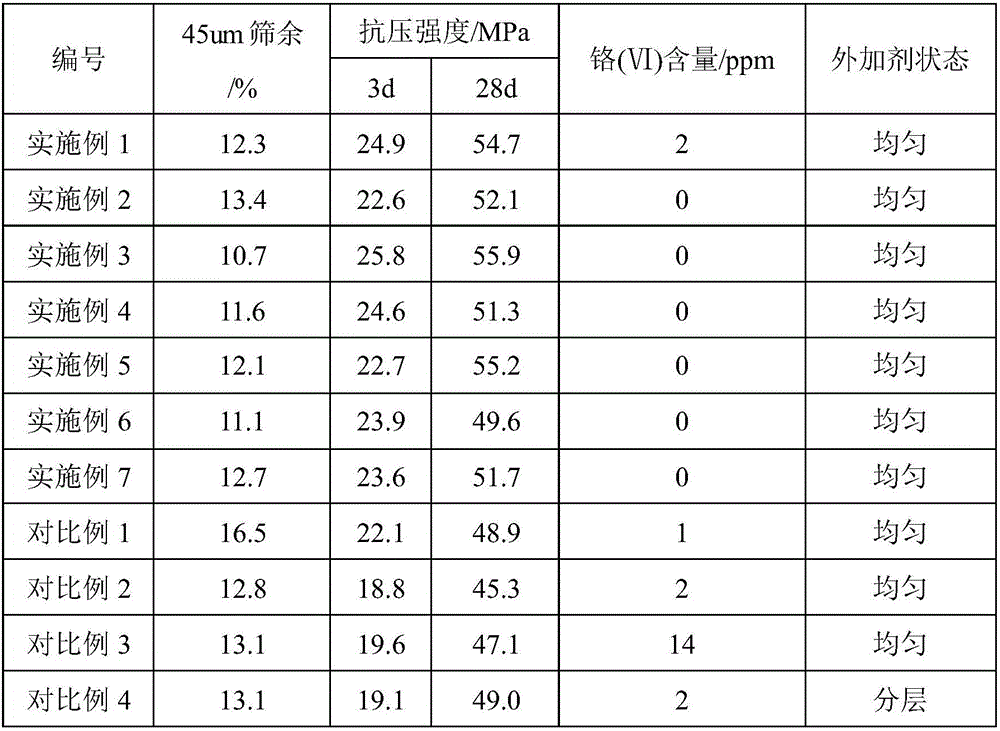

Examples

Embodiment 1

[0021] An environment-friendly cement process admixture, which is composed of the following substances in weight percentage: 10% of grinding aid components, 10% of reinforcing components, 10% of hexavalent chromium reducing components, 2% of solubilizing components, and the balance for water;

[0022] The grinding aid component is composed of triethanolamine and triisopropanolamine in a weight ratio of 1:1;

[0023] The reinforcing component is composed of sodium formate and magnesium sulfate in a weight ratio of 1:1;

[0024] The hexavalent chromium reduction component is composed of ascorbic acid and diacid block in a weight ratio of 1:1;

[0025] The solubilizing component is composed of urea and sodium salicylate in a weight ratio of 1:1.

Embodiment 2

[0027] An environment-friendly cement process admixture is composed of the following raw materials: 20% of grinding aid components, 20% of reinforcing components, 20% of hexavalent chromium reducing components, 5% of solubilizing components, and the balance is water;

[0028] The grinding aid component is triethanolamine lauryl sulfate;

[0029] The reinforcing component is composed of sodium acetate and sodium benzoate in a weight ratio of 2:1;

[0030] The hexavalent chromium reducing component is sodium hypophosphite;

[0031] The solubilizing component is urea.

Embodiment 3

[0033] An environment-friendly cement process admixture is composed of the following raw materials: 12% of grinding aid components, 15% of reinforcing components, 13% of hexavalent chromium reducing components, 3% of solubilizing components, and the balance is water;

[0034] The grinding aid component is composed of hexamethylenetetramine, tripropylene glycol and triethanolamine lauryl sulfate in a weight ratio of 3:2:1;

[0035] The reinforcing component is composed of sodium benzoate and magnesium sulfate in a weight ratio of 1:1;

[0036] The hexavalent chromium reducing component is composed of ascorbic acid, diacid, sodium hypophosphite and carbohydrazide in a weight ratio of 1:3:2:1;

[0037] The solubilizing component is composed of sodium salicylate and acetamide in a weight ratio of 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com