Embedded-type all-grain-size dry magnetic separation technology for closed recycle of iron-containing minerals in steel slag

A full-grain grade, embedded technology, applied in the field of mineral processing and comprehensive utilization of resources, can solve the problem of inconsistency in the magnetic properties of fine-grained steel slag iron-containing minerals and reduce the The service life of the grinding mill and other issues can be reduced to reduce the power consumption of the grinding, increase the economic benefits and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described in conjunction with following example (accompanying drawing):

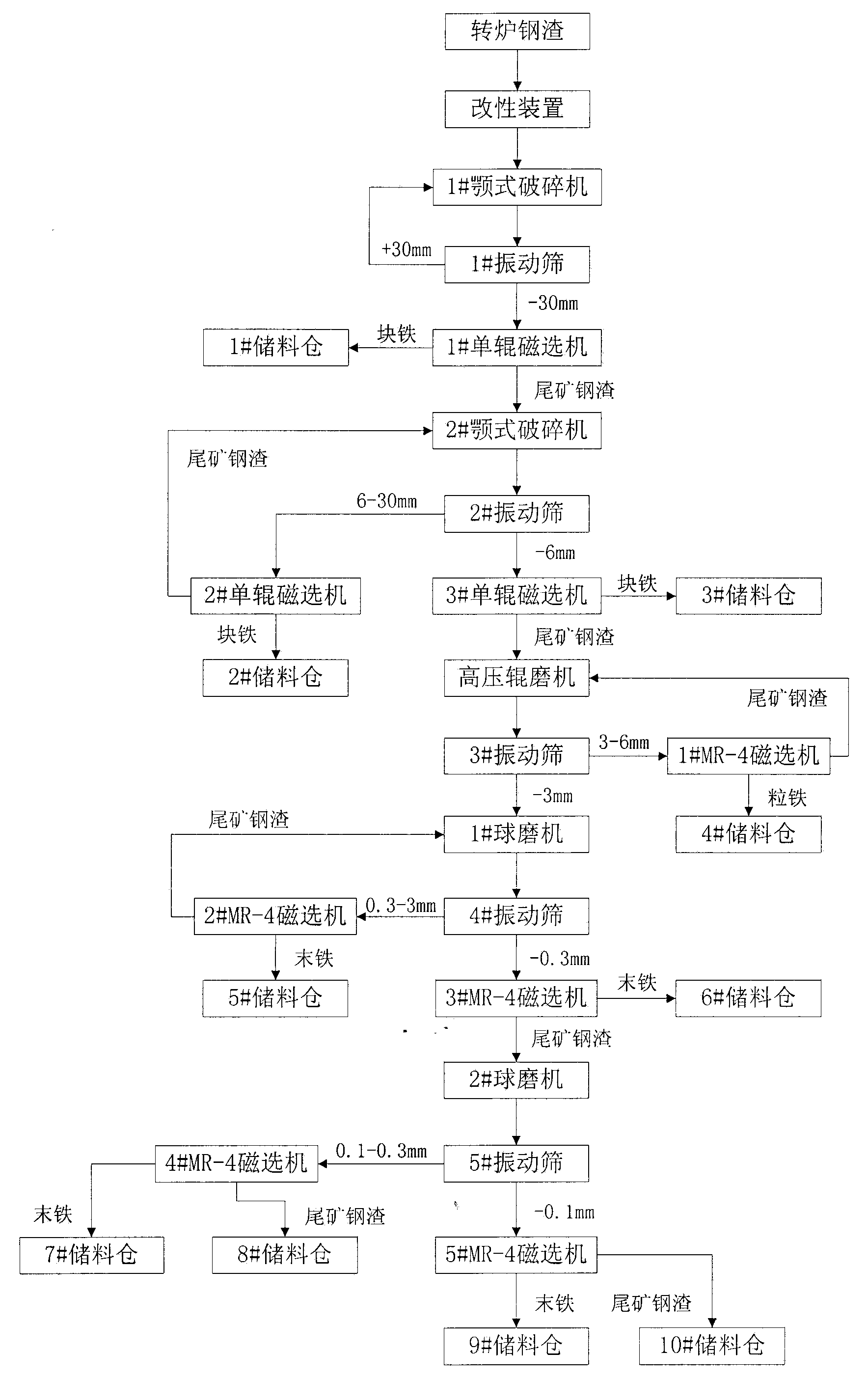

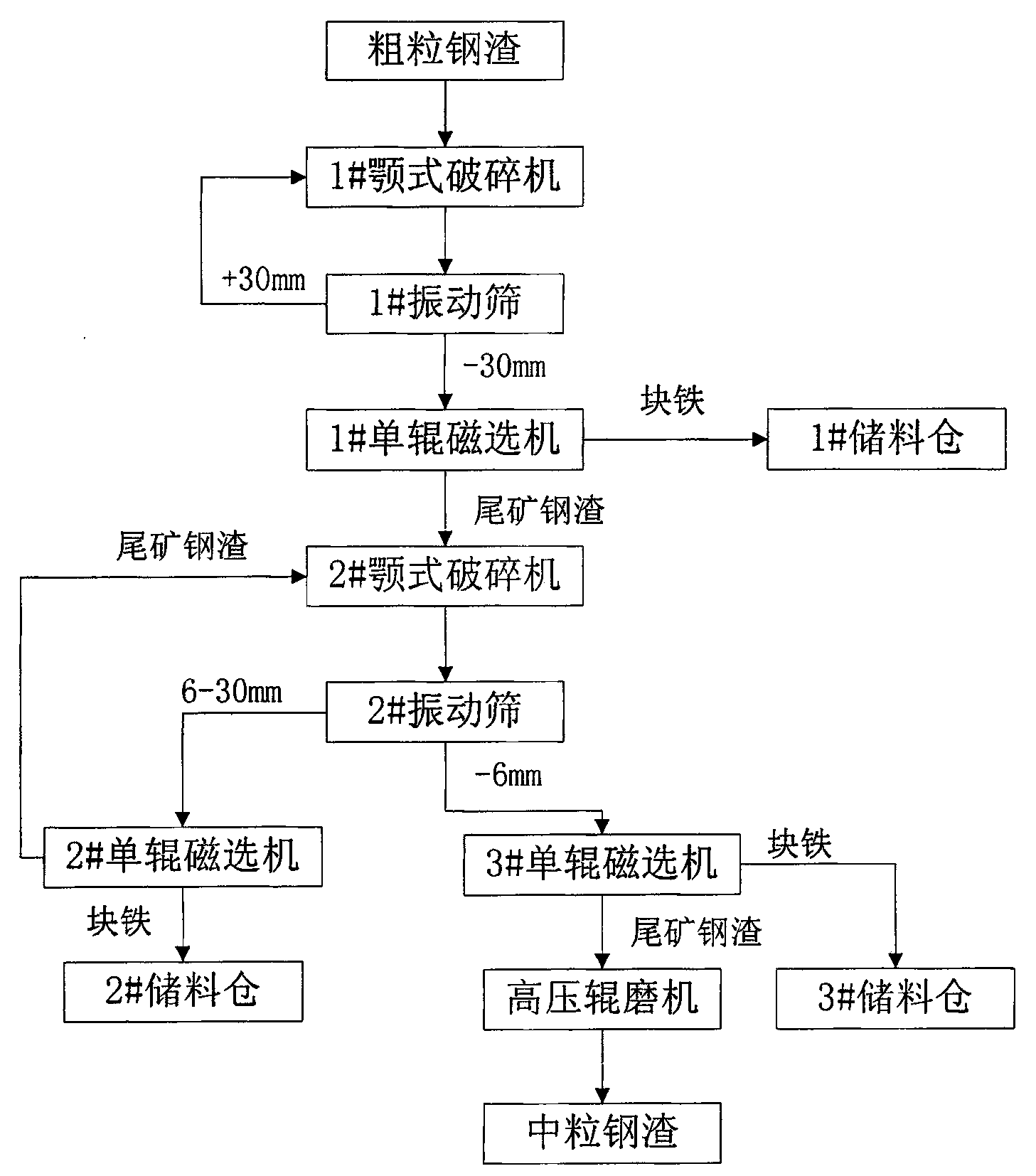

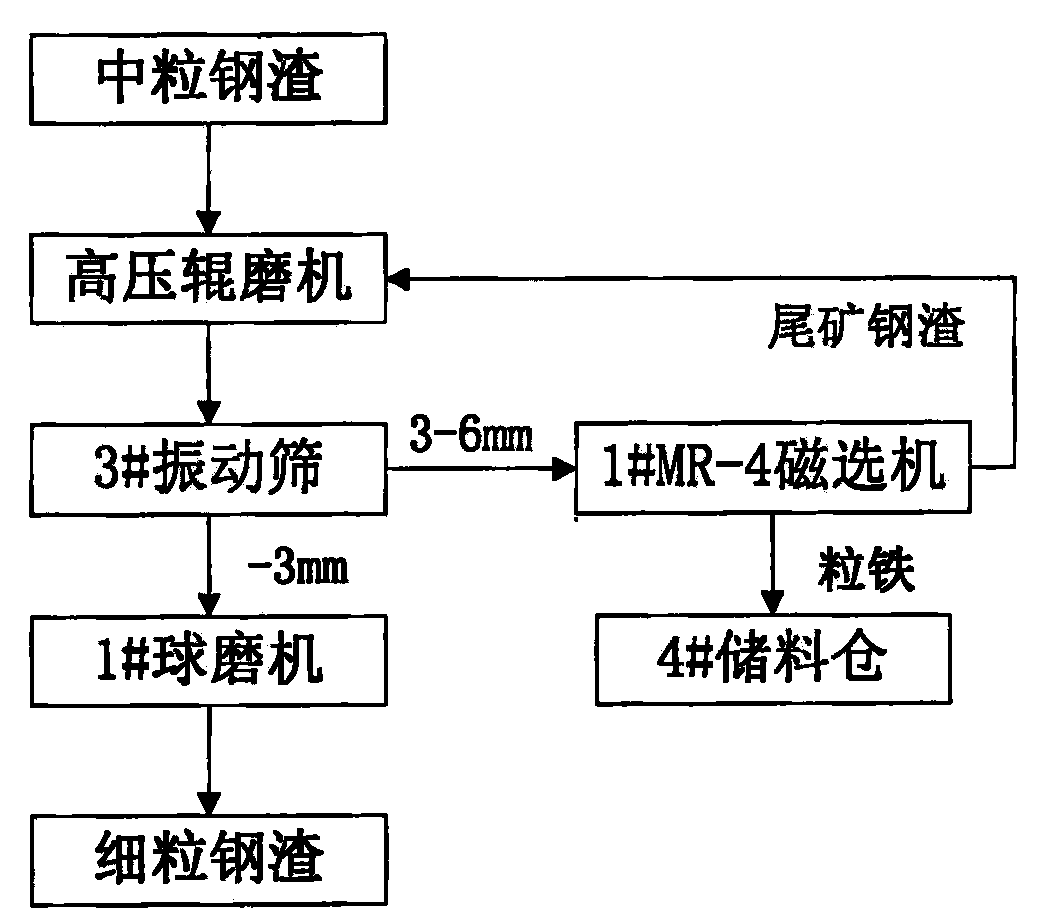

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the dry magnetic separation process of the present invention's embedded full-grain closed-circuit recovery of iron-containing minerals in steel slag mainly includes: modification of steel slag; treatment of coarse-grained steel slag; treatment of medium-grained steel slag; deal with.

[0029] Such as figure 1 As shown, the specific process flow of the embedded full-grain closed-circuit recovery steel slag iron dry magnetic separation process of the present invention is as follows:

[0030] When dumping steel slag in the steel furnace, add lignite as a reduction modifier, wherein the mass ratio of steel slag to reduction modifier is controlled at 8:0.75-1.4; the modified steel slag enters the 1# jaw crusher for crushing , the control particle size is 30mm; after the crushed steel slag is clas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com