Preparation method of functionalized adjustable amphiprotic polycarboxylates cement grinding aid

A technology of amphoteric polycarboxylic acid and cement grinding aid, applied in the field of building materials, can solve the problems of poor stability, poor pertinence and poor adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 80g of allyl polyoxyethylene ether, 6g of sodium methacrylate and 100g of water were placed in the reactor; 10g of maleic anhydride, 0.2g of copper bromide, 0.2g of 1,10-phenanthroline and 20g of Water was configured as aqueous solution A, and 1 g of ammonium persulfate and 30 g of water were configured as aqueous solution B. The reaction kettle began to heat up under the protection of nitrogen gas. When the temperature reaches 75-95°C, add the aqueous solutions A and B dropwise at the same time for 3 hours; after the dropwise addition, continue the reaction for 1 hour. After the reaction, add 20g of sodium hydroxide for neutralization, and add 30g of water to dilute to 40% concentration to obtain the finished product.

Embodiment 2

[0019] 90g of methyl alkenyl polyoxyethylene ether, 4g of 2-acrylamido 2-methylpropanesulfonic acid and 100g of water are placed in the reaction kettle; 15g of acrylic acid, 0.15g of copper bromide, 0.15g of cuprous bromide , 0.3g of 2,2'-bipyridine and 20g of water are configured into aqueous solution A, and 5g of sodium persulfate and 30g of water are configured into aqueous solution B. The reaction kettle began to heat up under the protection of nitrogen gas. When the temperature reaches 75-95°C, add the aqueous solution A and B dropwise at the same time, and the dropwise addition time is 5h; after the dropwise addition, continue the reaction for 1h. After the reaction, add 10g of sodium hydroxide for neutralization, and add 30g of water to dilute to 40% concentration to obtain the finished product.

Embodiment 3

[0021] 100g of methyl alkenyl polyoxyethylene ether, 5g of sodium vinyl sulfonate and 100g of water are placed in a reactor; Nonyl)-2,2'-bipyridine and 20g of water are configured into aqueous solution A, and 3g of hydrogen peroxide and 30g of water are configured into aqueous solution B. The reaction kettle began to heat up under the protection of nitrogen gas. When the temperature reaches 75-95°C, add the aqueous solution A and B dropwise at the same time, and the dropwise addition time is 4h; after the dropwise addition, continue the reaction for 1h. After the reaction, add 5g of sodium hydroxide for neutralization, and add 60g of water to dilute to 40% concentration to obtain the finished product.

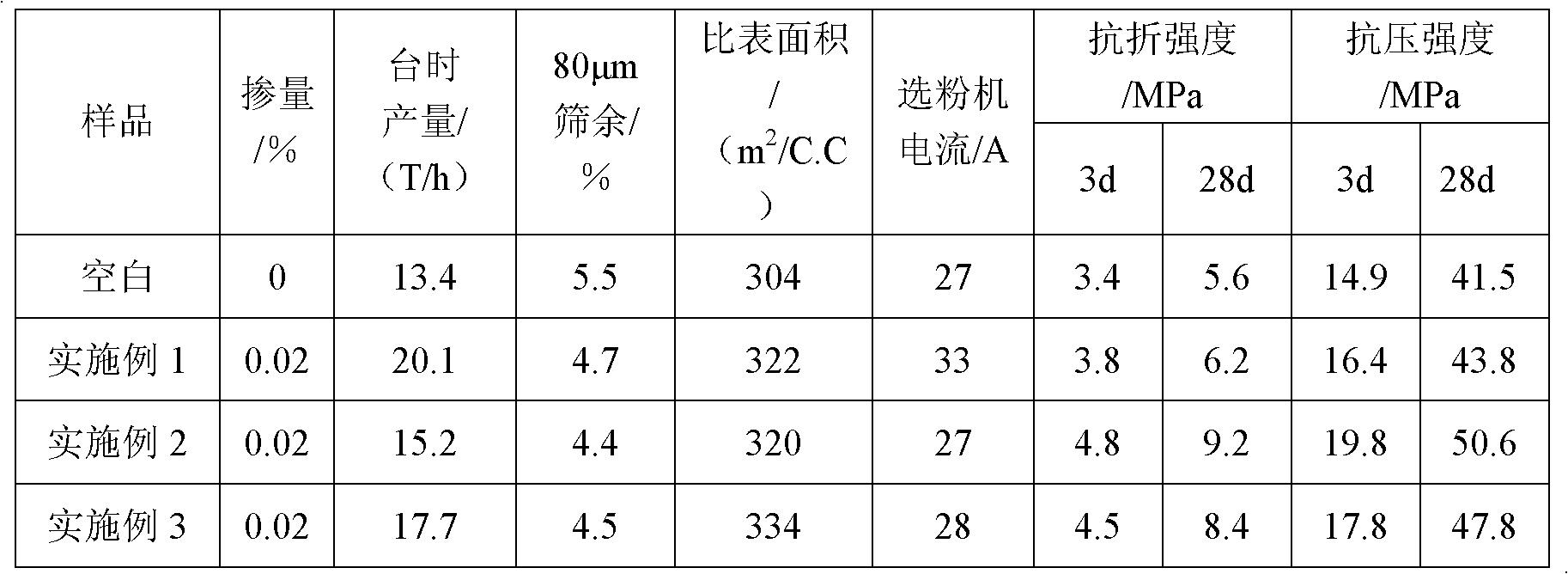

[0022] Refer to GB1345-2005 for the inspection method of cement fineness; refer to GB8074-87 for the inspection method of cement specific surface area; refer to JC / T667-2004 for concrete performance test, and the cement dosage is 307kg / m 3 , The sand rate is 45%, and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com