Preparation method of functionalized adjustable amphiprotic polycarboxylates cement grinding aid

A technology of amphoteric polycarboxylic acid and cement grinding aid, applied in the field of building materials, can solve the problems of poor pertinence, poor adaptability, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 80g allyl polyoxyethylene ether, 6g sodium methacrylate and 100g water are placed in the reactor; 10g maleic anhydride, 0.2g copper bromide, 0.2g1, 10-phenanthroline and 20g Water was prepared as aqueous solution A, and 1 g of ammonium persulfate and 30 g of water were prepared as aqueous solution B. The reaction kettle began to heat up under nitrogen protection. When the temperature reaches 75-95°C, the aqueous solutions A and B are added dropwise at the same time, and the dropwise addition time is 3 hours; after the dropwise addition, the reaction is continued for 1 hour. After the reaction, 20 g of sodium hydroxide was added for neutralization, and 30 g of water was added to dilute to a concentration of 40% to obtain a finished product.

Embodiment 2

[0019] 90g methylalkenyl polyoxyethylene ether, 4g of 2-acrylamido 2-methylpropanesulfonic acid and 100g of water were placed in the reactor; 15g of acrylic acid, 0.15g of copper bromide, 0.15g of cuprous bromide were placed in the reactor; , 0.3 g of 2,2'-bipyridine and 20 g of water were configured as aqueous solution A, and 5 g of sodium persulfate and 30 g of water were configured as aqueous solution B. The reaction kettle began to heat up under nitrogen protection. When the temperature reached 75-95°C, aqueous solutions A and B were added dropwise at the same time, and the dropwise addition time was 5h; after the dropwise addition, the reaction was continued for 1h. After the reaction, 10 g of sodium hydroxide was added for neutralization, and 30 g of water was added to dilute to a concentration of 40% to obtain a finished product.

Embodiment 3

[0021] 100g methyl alkenyl polyoxyethylene ether, 5g sodium vinyl sulfonate and 100g water are placed in the reactor; 30g methacrylic acid, 0.1g cuprous bromide, 0.5g 4,4'-bis(5- Nonyl)-2,2'-bipyridine and 20 g of water were prepared as aqueous solution A, and 3 g of hydrogen peroxide and 30 g of water were prepared as aqueous solution B. The reaction kettle began to heat up under nitrogen protection. When the temperature reaches 75-95°C, the aqueous solutions A and B are added dropwise at the same time, and the dropwise addition time is 4 hours; after the dropwise addition, the reaction is continued for 1 hour. After the reaction, 5 g of sodium hydroxide was added for neutralization, and 60 g of water was added to dilute to a concentration of 40% to obtain a finished product.

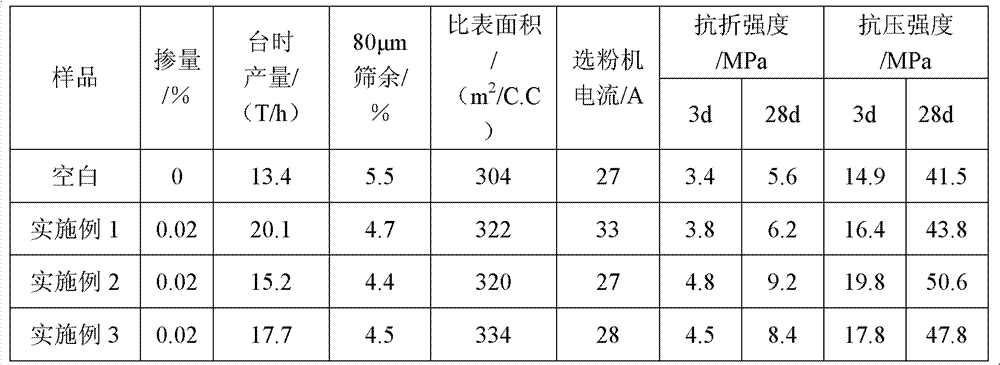

[0022] Refer to GB1345-2005 for cement fineness inspection method; refer to GB8074-87 for cement specific surface area inspection method; refer to JC / T667-2004 for concrete performance test, in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com