Activating agent for S75-grade high-titanium slag micro-powder

A technology of slag powder and activator, which is applied in the field of concrete materials, can solve the problems of low mixing amount, high grinding power consumption, low activity, etc., and achieve simple process, reduce grinding power consumption, accelerate hydration rate and hydration degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The raw materials used in this embodiment and their ratio are: 100% mixed slag, 75% of high-titanium blast furnace slag, and 25% of ordinary slag. The remaining components are calculated according to the mass percentage of mixed slag, including the following components and proportions: metakaolin 2.5%, fly ash 1.5%; water glass 0.3%, caustic soda 0.15%; ethylene glycol 0.02%, methyldiethanolamine 0.005% .

[0022] Pre-mix the water glass, caustic soda and metakaolin weighed in proportion, wherein the specific surface area of metakaolin is not less than 200m 2 / kg; Ethylene glycol and methyldiethanolamine are slowly and evenly added to the above mixture, after mixing evenly, let it stand and age for not less than 1 hour to obtain the activator.

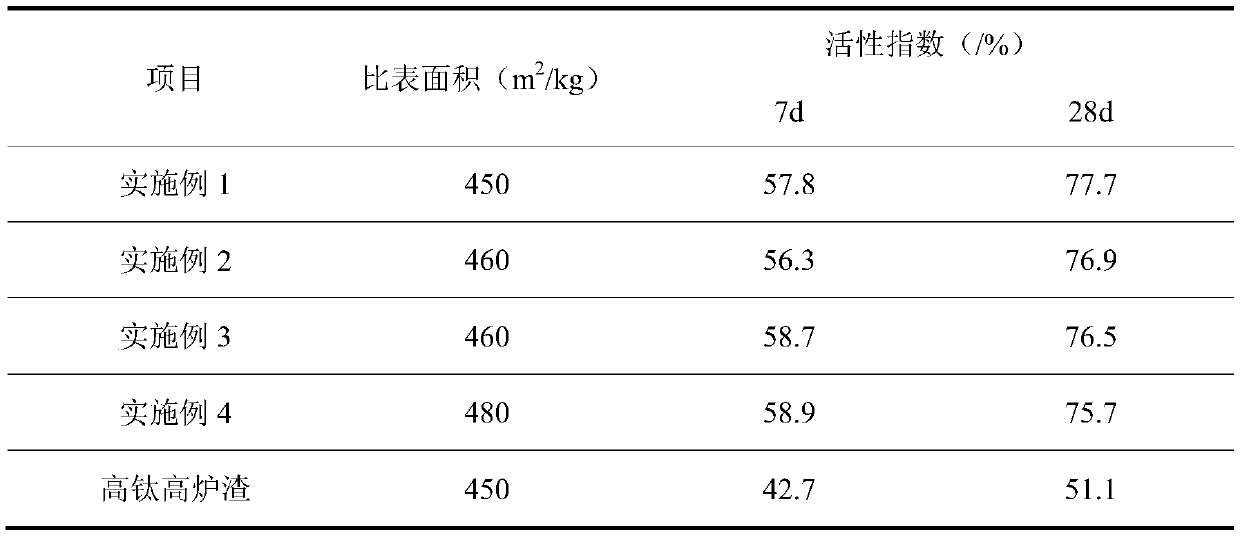

[0023] The samples were prepared according to the requirements of "Granulated Blast Furnace Slag Powder Used in Cement, Mortar and Concrete" (GB / T 18046-2017). After curing to the corresponding age, the test results are shown...

Embodiment 2

[0025] The specific implementation process is the same as in Example 1, the difference is that the proportion of mixed slag used is different, specifically, the high-titanium blast furnace slag is 83%, and the common slag is 17%;

Embodiment 3

[0027] The specific implementation process is the same as in Example 1, the difference is that the amount and proportion of the silicon-aluminum materials used are different, specifically, 4.8% of fly ash.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com