Cement external-circulation vertical milling preparation system capable of adjusting particle size distribution

A particle size distribution and preparation system technology, applied in cement production, etc., can solve problems such as short waiting time, narrow range of cement particle size distribution, and difficulty in over-grinding, so as to achieve low power consumption and good grinding performance. The effect of cement properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

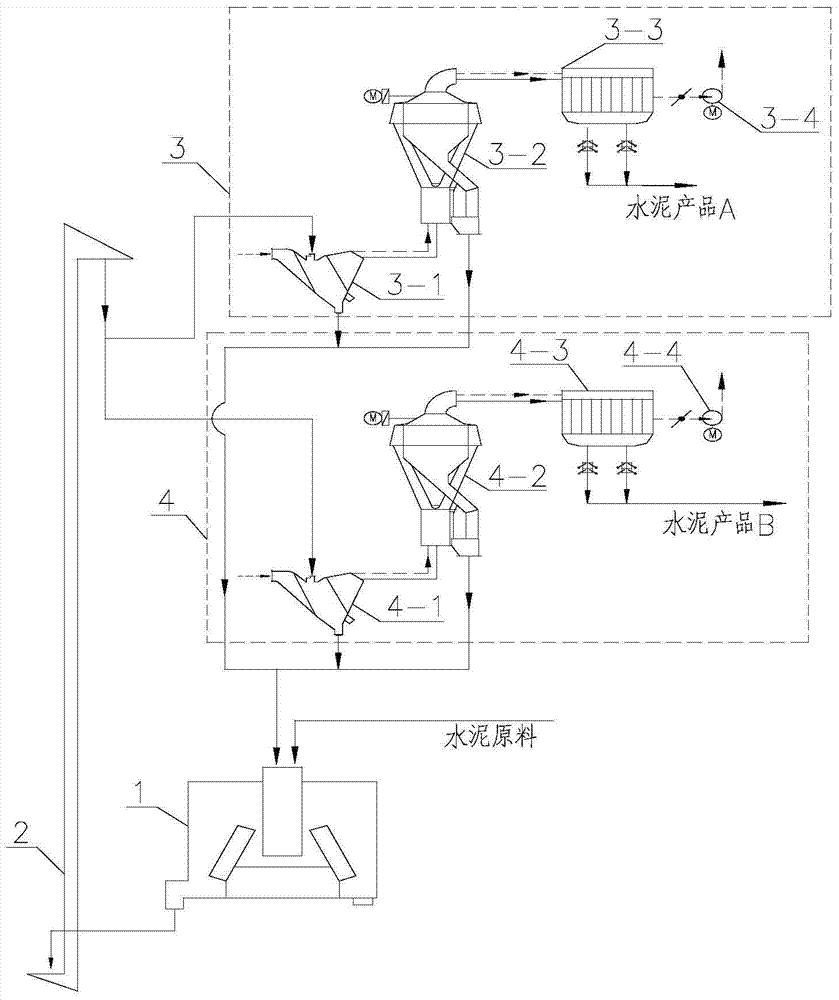

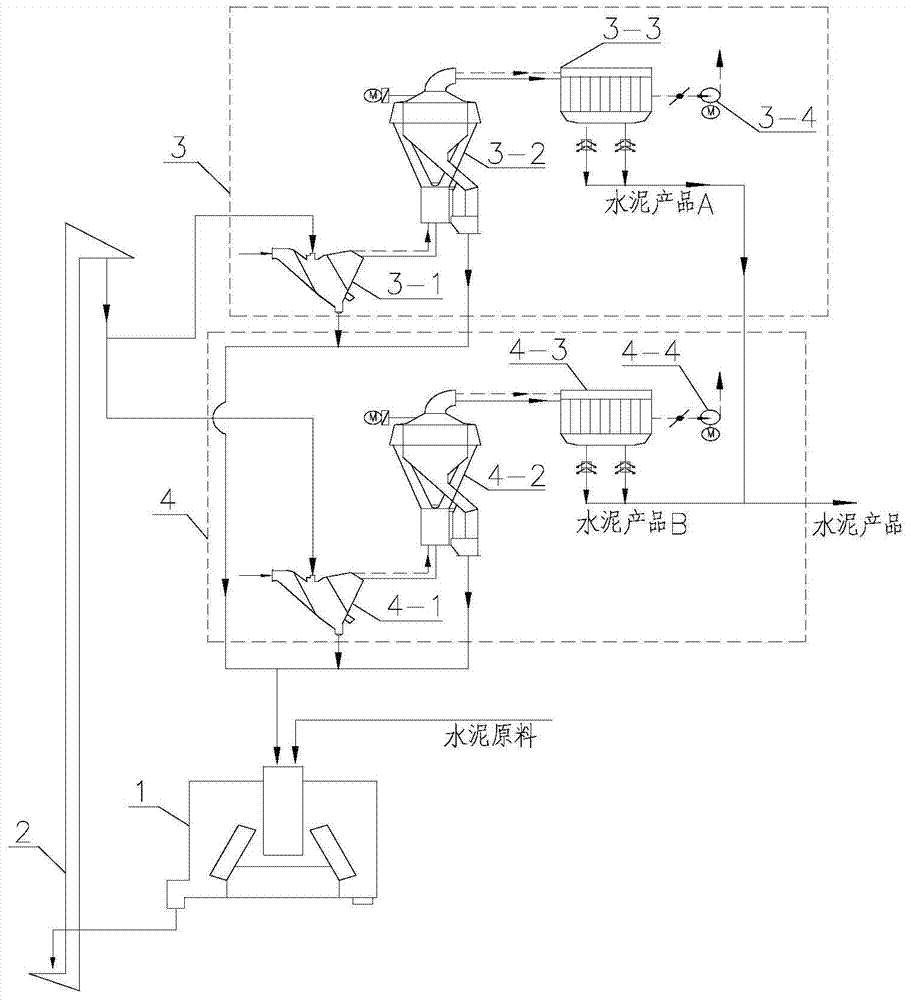

[0027] Another embodiment of the improvement of the present invention, such as figure 2 , the cement product A collected by the first dust collector 3-3 and the cement product B collected by the second dust collector 4-3 are mixed together in different proportions to obtain mixed cement with different particle size distribution ranges. Mix in any ratio.

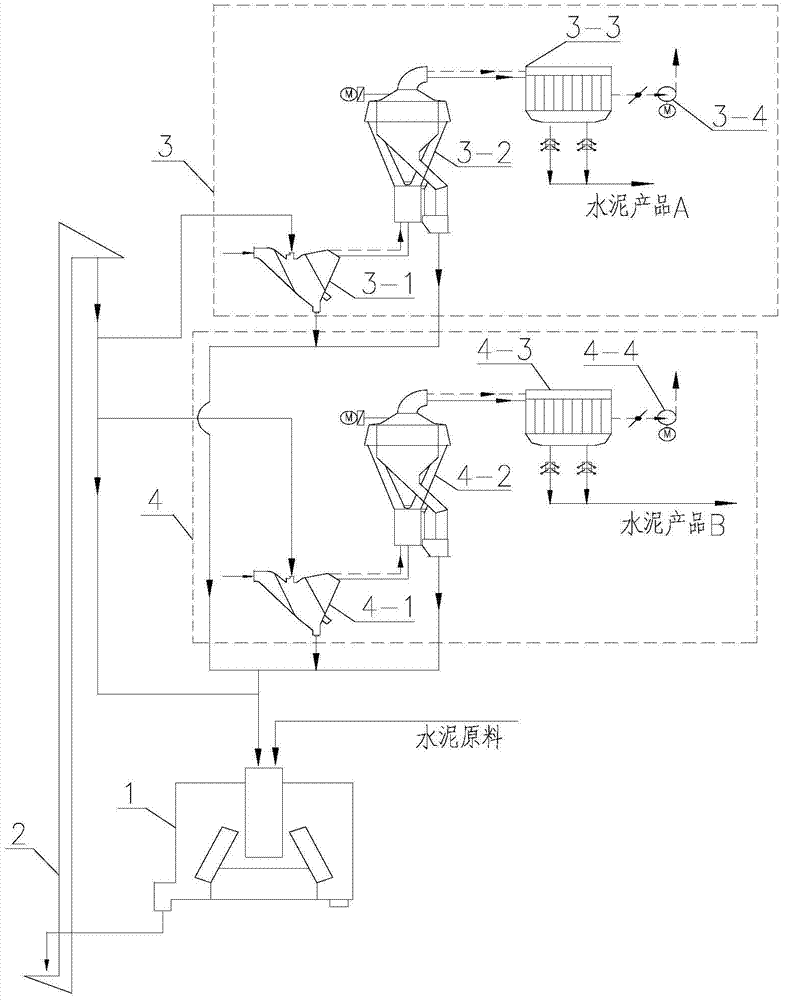

[0028] Another improved embodiment of the present invention, such as image 3 , the material behind the bucket elevator 2 is divided into two paths, the first path directly returns to the vertical mill 1, and the second path enters the various cement powder separation subsystems connected in parallel after the bucket elevator 2, and the material amount of the first path is controlled at 0-30% , to realize that a small part of the powder containing the fine powder of the finished cement product is returned to the vertical mill 1 for cyclic grinding, which is helpful for the stable operation of the vertical mill, and can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com