External-circulation cement finish grinding system for vertical mill

An external circulation, vertical mill technology, applied in cement production and other directions, can solve problems such as difficulty in adapting, loss of hot air drying function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

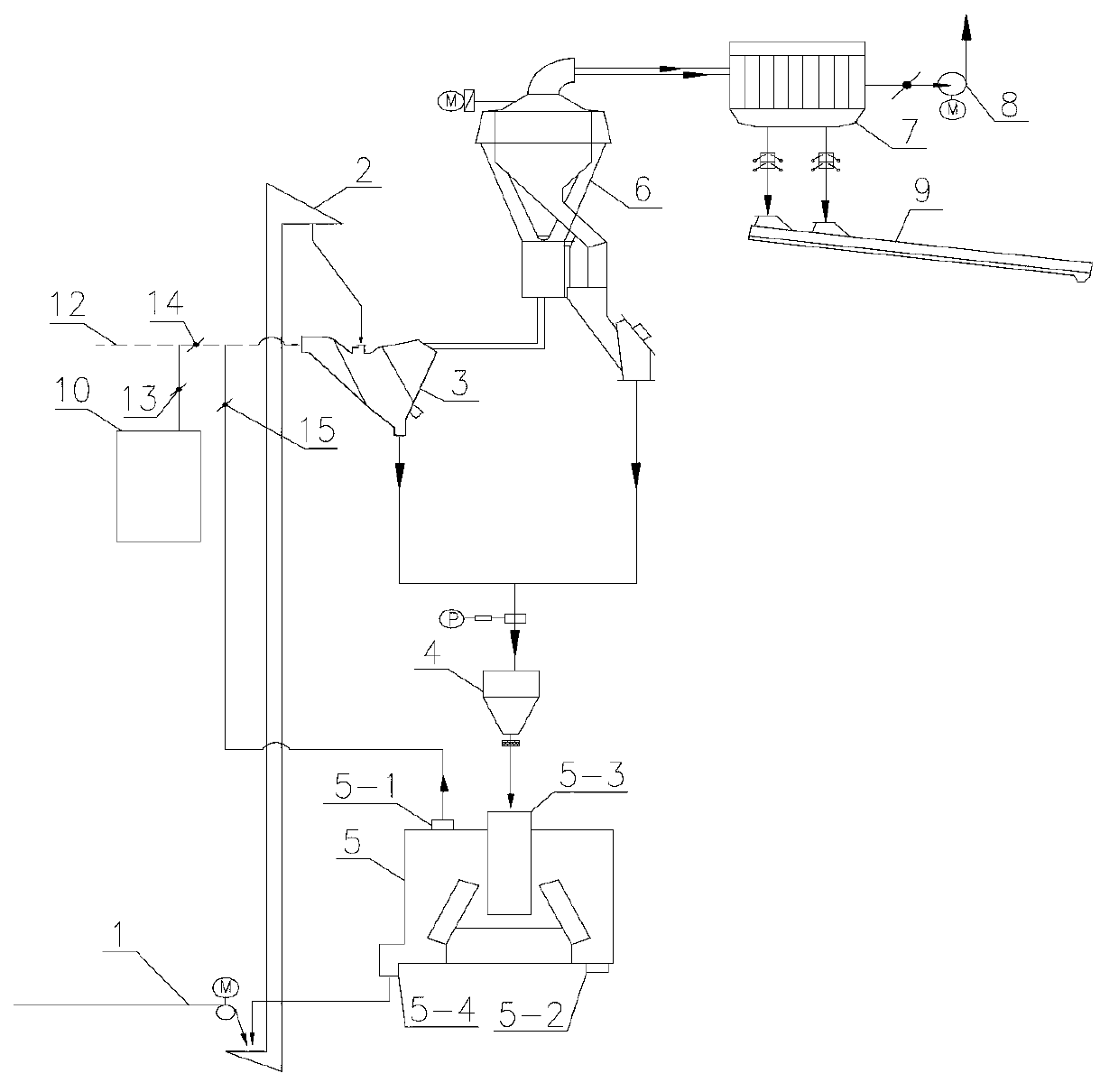

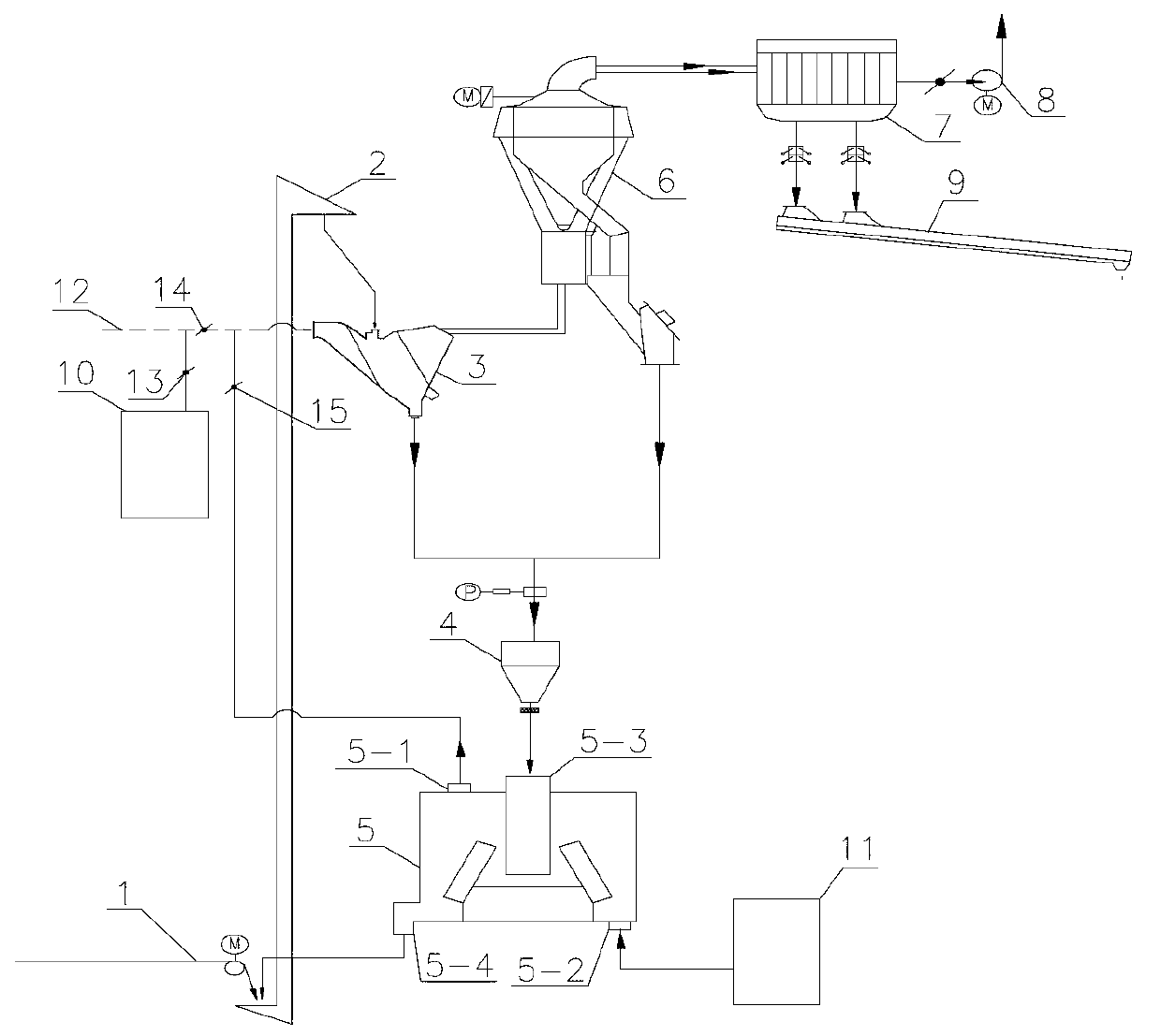

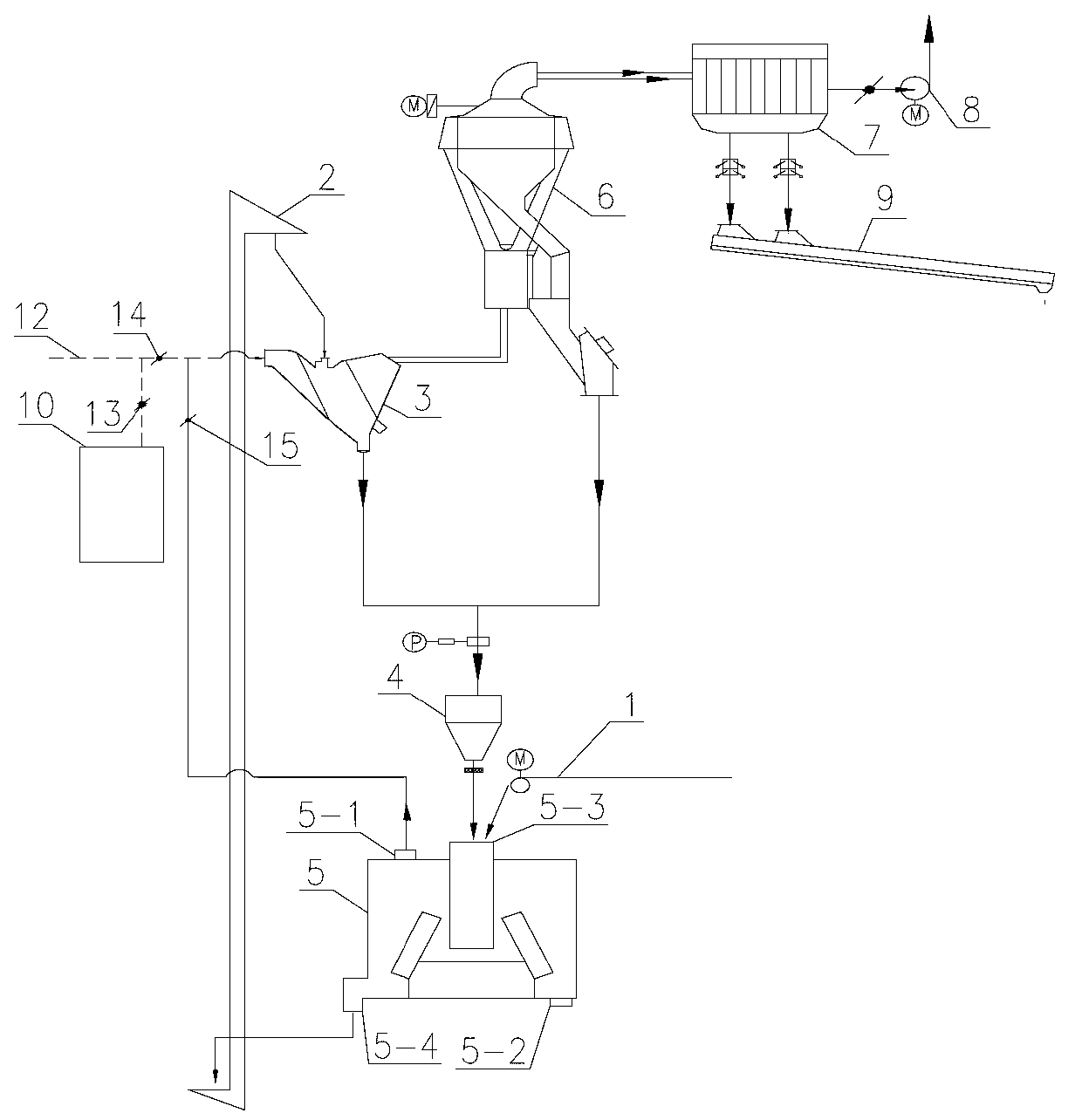

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as Figure 1 to Figure 4 As shown, the present invention provides an external circulation cement vertical mill final grinding system, including a belt conveyor 1, a bucket elevator 2, a steady flow bin 4, a vertical mill 5, a dust collector 7, a fan 8, and a chute 9; Belt conveyor 1 is used to transport materials, and chute 9 is used to transport fine powder materials; bucket elevator 2, coarse powder separator 3, steady flow bin 4, and vertical mill 5 are connected in sequence to form a circulation system; bucket elevator 2. Coarse powder separator 3, fine powder separator 6, steady flow bin 4, and vertical mill 5 are connected in sequence to form a circulation system; bucket elevator 2, coarse powder separator 3, fine powder separator 6, collection The duster 7 and the fan 8 are connected in sequence; the vertical mill 5 is provided with a feed inlet 5-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com