Residual heat boiler of steel ball dedusting type ore heat furnace

A technology of waste heat boiler and submerged arc furnace, which is applied in the field of waste heat boiler to achieve the effect of light density, simple structure and super fine ash particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

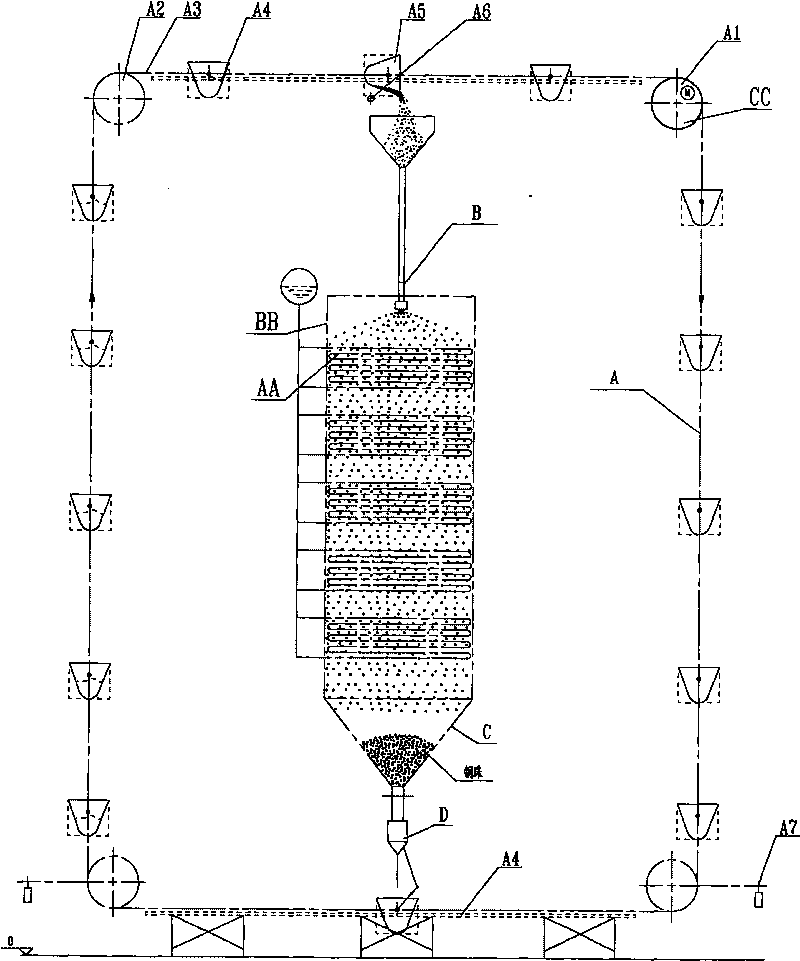

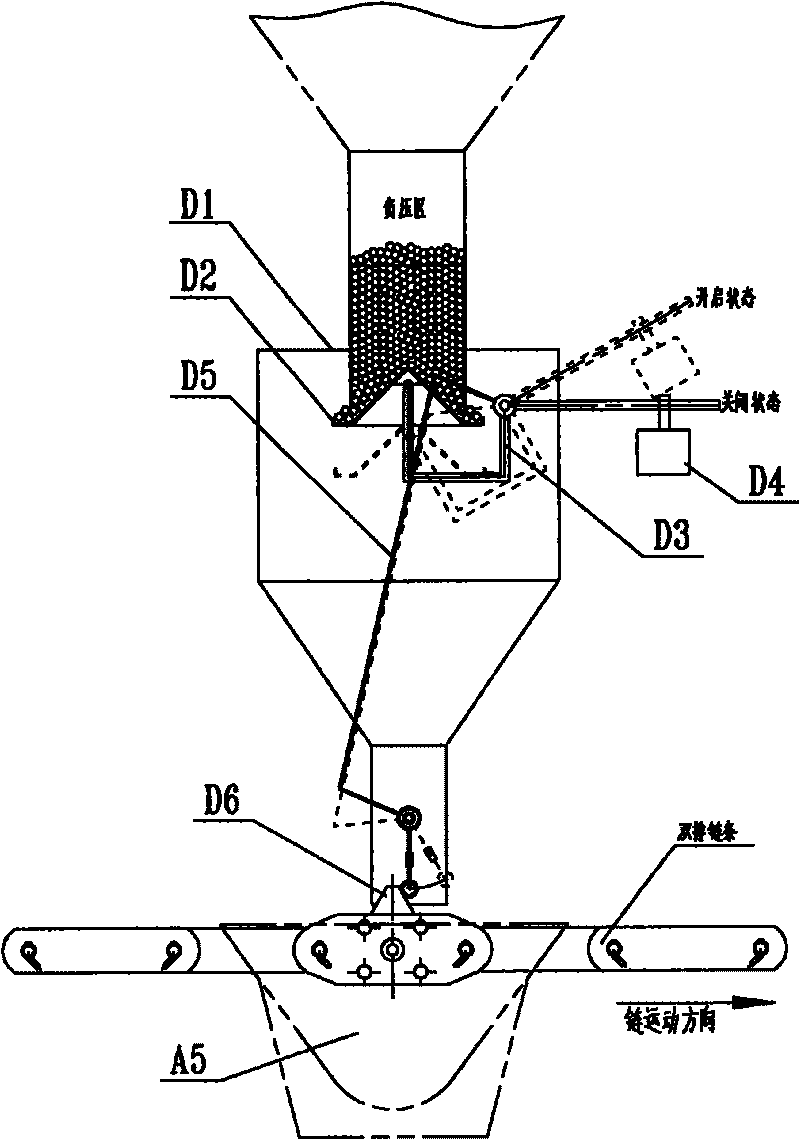

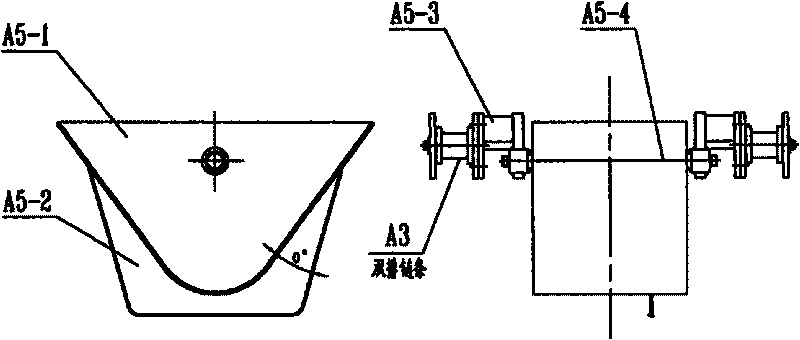

[0026] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention is mainly composed of three interrelated components: the boiler heating surface AA, the boiler flue gas channel BB, and the boiler dust removal device CC.

[0027] Boiler heating surface AA: It is composed of a serpentine tube group. The heated water or steam flows inside the tube, and the high-temperature ash-containing flue gas flows out of the tube. The function is to efficiently transfer the high-temperature physical heat on the flue gas side to the water or steam inside the tube. The thermal energy or potential energy that makes the water or steam in the pipe have a certain utilization value.

[0028] Boiler flue gas channel BB: A sealed channel is formed around the heating surface of the boiler, forcing the flue gas to pass through the heating surfaces of the boiler at all levels one by one, and form a furnace top and bottom at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com