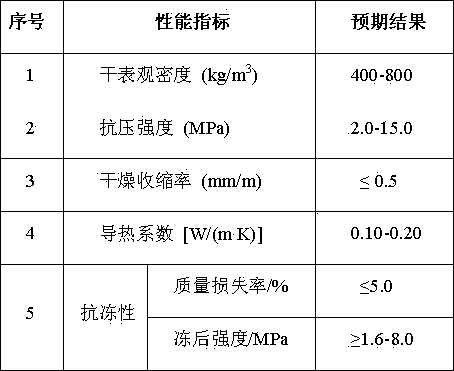

Autoclaved aerated concrete and preparation method thereof

An autoclaved aeration, concrete technology, applied in ceramic products, climate sustainability, other household appliances, etc., can solve the overall situation that is not conducive to the comprehensive utilization of solid waste, reduce the utilization of bulk solid waste, etc., and achieve cost Low, excellent performance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Another embodiment of the present invention provides the preparation method of the above-mentioned autoclaved aerated concrete, including:

[0058] (1) Preparation of basic activator

[0059] Choose sodium (potassium) water glass and NaOH / KOH as raw materials, dissolve NaOH / KOH in water, and control the molar concentration at 5~15mol / L; choose sodium (potassium) water glass, and control the modulus to 2~3.5; or mixed, control the overall modulus of the mixture at 1.0~2.0; stir for 1~10min, put in a plastic container, and let stand for 12~48h.

[0060] (2) Mix and stir

[0061] Mix mineral raw materials, alkaline activator, foam stabilizer and water, and then mix and stir with foaming agent and desulfurized gypsum. The stirring time is 1-10 minutes, and it can be stirred for 1, 3, 5, 7, 10 minutes, etc. until the stirring Uniform;

[0062] (3) Pouring

[0063] Pour the slurry into the mold, and adjust the pouring spread to about 15%;

[0064] (4) Rest

[0065] Afte...

Embodiment 1

[0073] Measure 350g of sodium water glass, with a modulus of 3.25 and a density of 1.38g / ml; weigh 40g of NaOH and 40g of water and mix evenly, then mix evenly with water glass and 0.27g of foam stabilizer, and place it for 24 hours to form a liquid alkaline stimulant.

[0074] Weigh 300g of Class I fly ash as mineral raw material, weigh 15g of H 2 o 2 Foaming agent, 6g desulfurized gypsum, added to the mineral raw materials, and mixed evenly.

[0075] Mix the liquid alkaline activator with the solid raw material, stir evenly, add foaming agent, and stir for 3 minutes.

[0076] Pouring the mixed material into steel or plastic moulds, sealed, 60 o C under rest for 60min.

[0077] The green body is turned over and demolded, and cut with a cutting machine to remove excess bottom material and top material.

[0078] Put the cut semi-finished product into the autoclave at a temperature of 90 o C, under the conditions of pressure 0.3MPa, curing humidity 90%, curing for 4 hours,...

Embodiment 2

[0082] Measure 240g of sodium water glass, with a modulus of 3.25 and a density of 1.38g / ml; weigh 37g of NaOH and 60g of water and mix evenly, then mix evenly with water glass and 0.16g of foam stabilizer, leave it for 24 hours, and use it as a liquid alkaline stimulant.

[0083] Weigh 240g of Class II fly ash, 60g of slag as mineral raw material, weigh 9g H 2 o 2 Foaming agent, 9g desulfurized gypsum, added to the mineral raw materials, and mixed evenly.

[0084] Mix the liquid alkaline activator with the solid raw material, stir evenly, add foaming agent, and stir for 1 min.

[0085] Pouring the mixed material into steel or plastic moulds, sealed, 60 o Rest at C for 30min.

[0086] The green body is turned over and demolded, and cut with a cutting machine to remove excess bottom material and top material.

[0087] Put the cut semi-finished product into the autoclave at a temperature of 100 o C, under the conditions of pressure 0.5MPa, curing humidity 70%, curing for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com