Detoxification graded resource utilization method for household garbage incineration fly ash

A technology for incineration and recycling of domestic waste, applied in the improvement of process efficiency, removal of solid waste, etc., can solve the problems of high cost, difficult recycling of useful resources, poor harmless effect of fly ash, etc. Solve the serious excess of heavy metals and waste of useful resources, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of permeable bricks after detoxification of fly ash

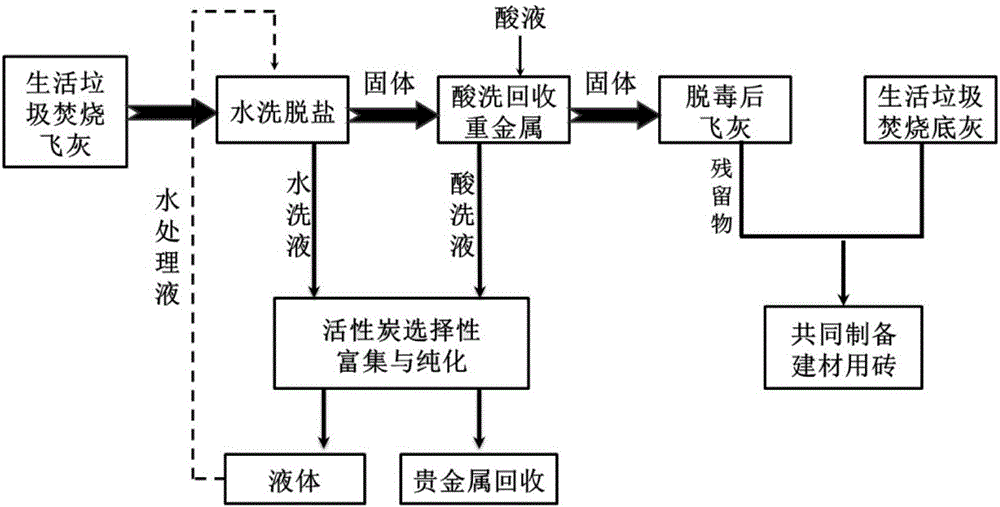

[0038] A method for detoxification and graded resource utilization of domestic waste incineration fly ash, such as figure 1 shown, including the following steps:

[0039] (1) Mix domestic waste incineration fly ash and water at a mass volume ratio of 1:10g / ml, and mix with mechanical stirring for 1 hour to ensure that soluble salts and chlorine are fully dissolved to form a mortar. After washing with water, the mass of soluble salt dissolved in water accounts for about 29% of the weight of the original fly ash, and the removal rate of chlorine in the original fly ash is as high as 87%;

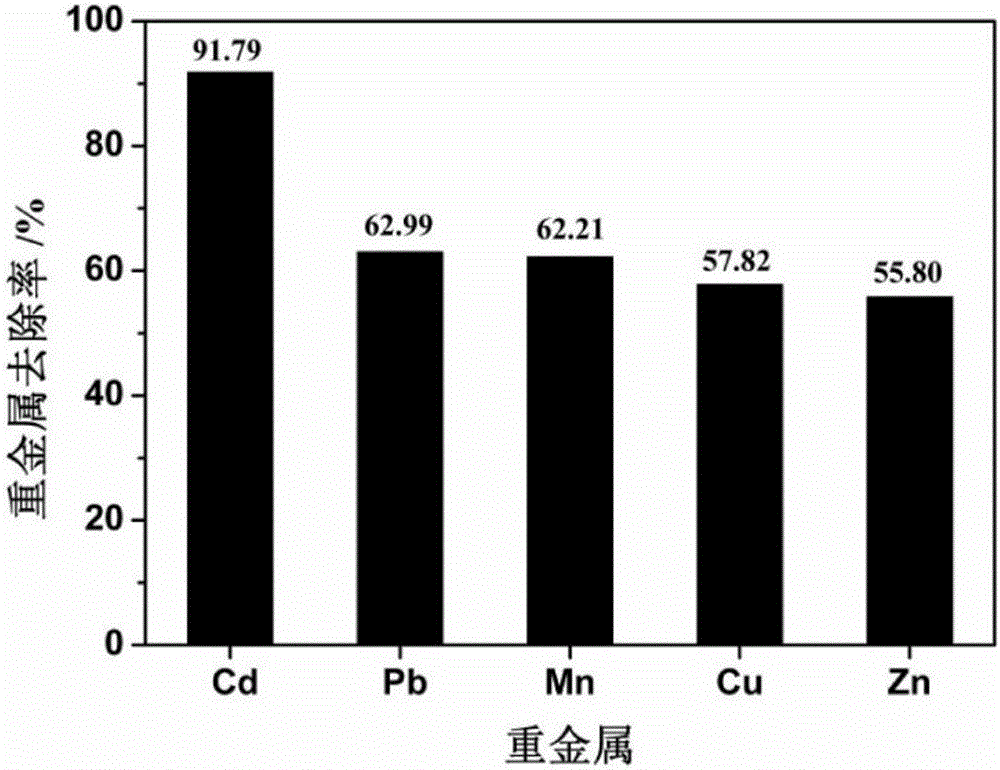

[0040] (2) Send the mortar obtained in step (1) into a centrifuge for dehydration, and separate the washing solution and the washed fly ash, wherein the washed fly ash and 1.5 mol / L nitric acid preparation solution are prepared according to the mass volume ratio of 1: Mix at a ratio of 10g / ml, pickle and remo...

Embodiment 2

[0048] Example 2: Recovery of precious metals in fly ash

[0049] This embodiment is the recovery of precious metals in the washing solution and pickling solution obtained in Example 1.

[0050] The washing liquid from the fly ash washed with the pickling liquid after the pickling of the fly ash is mixed directly, and left to settle for 1-3 hours. etc.), the activated carbon after enrichment and purification of precious metals can be used to recover precious metals, specifically: firstly, pickling is used to dissolve the precious metals adsorbed by activated carbon, and then separated from the solution (such as reduction precipitation method, solvent extraction method, etc.) and refining, Finally, pure products of precious metals are obtained. The recovery rate of precious metals is as high as 80%. Activated carbon after enrichment and purification of precious metals After recovery of precious metals, the activated carbon is activated at 600°C-1000°C under different atmosphe...

Embodiment 3

[0052] Example 3: Recovery of soluble salts in fly ash

[0053] This example is for the recovery of soluble salts in the remaining liquid phase after enrichment and purification of precious metals using activated carbon with selective adsorption function in Example 1.

[0054] In this embodiment, soluble salts are precipitated by evaporation and concentration of the solution. The evaporation concentration temperature is 80-100 ° C. The recoverable soluble salts are mainly sodium salts, magnesium salts and calcium oxides, etc. The recovery rate of soluble salts is as high as 90%. This achieves the purpose of recovering soluble salts in water samples. After the evaporated water is condensed, it can be recycled for washing the fly ash, and a certain volume of tap water is added again according to the mixing ratio of the fly ash and water during the washing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com