Self-supporting wire cable jacket extrusion mold

A self-supporting, cable technology, applied in the direction of conductor/cable insulation, etc., can solve the problems of poor cable appearance, loss of production enterprises, and difficulty in satisfying the use, etc., to achieve uniform thickness distribution of the sheath, durable molds, and matching proper effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

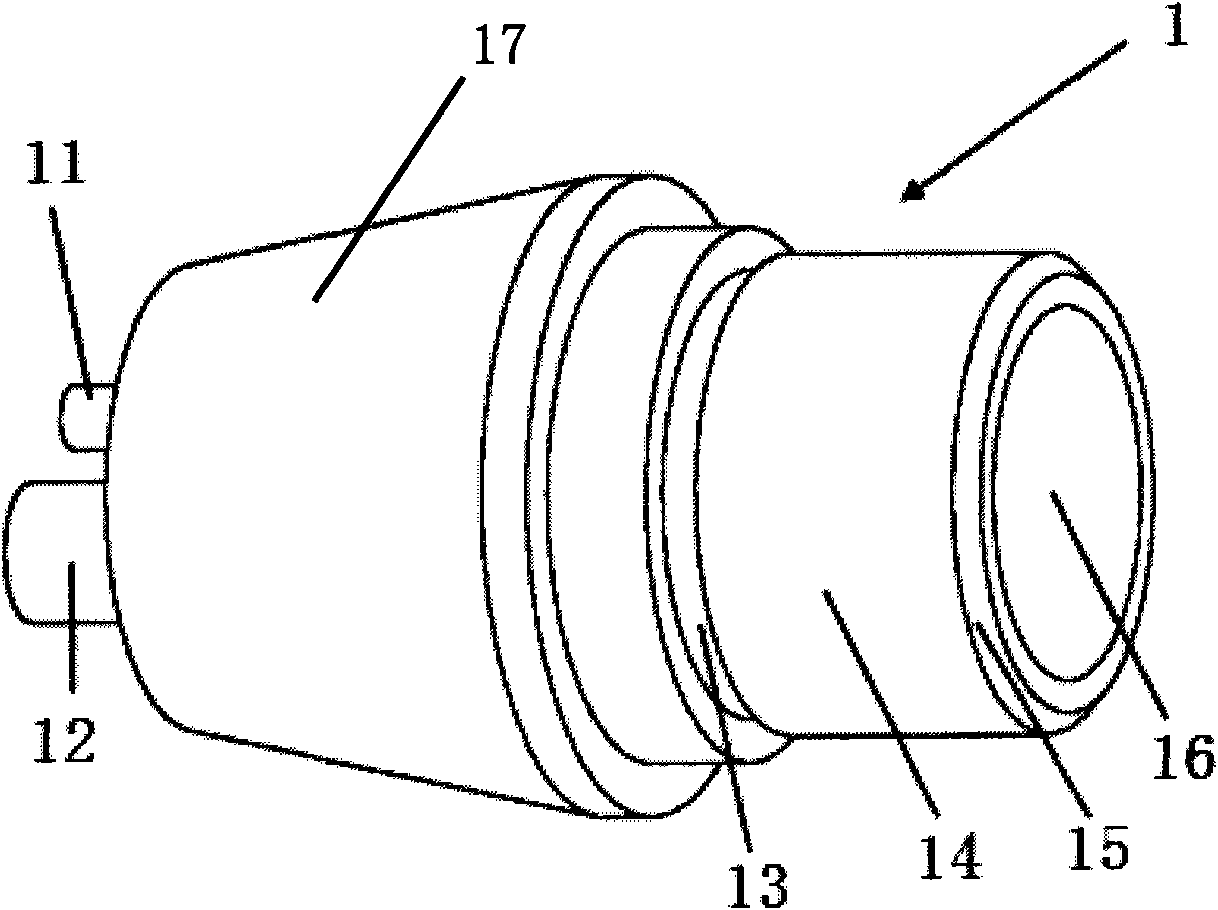

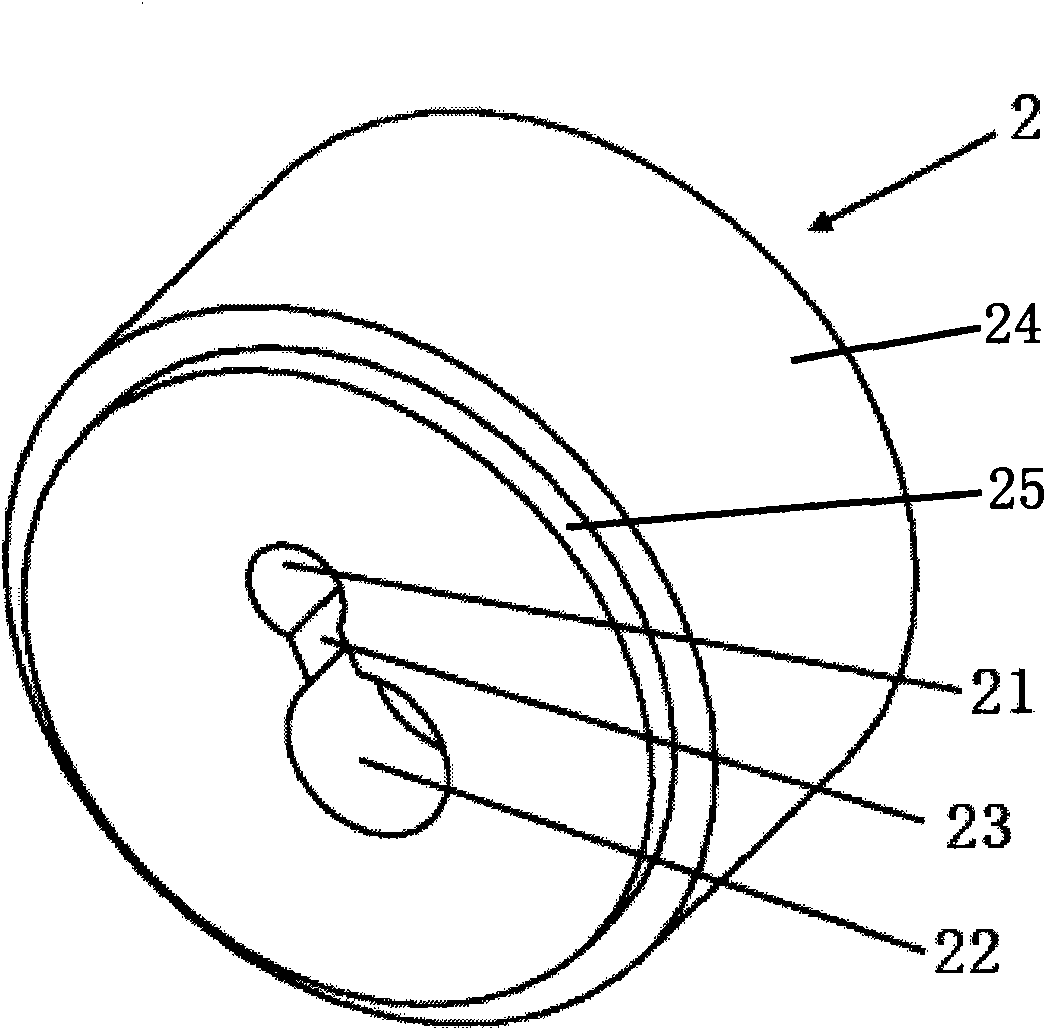

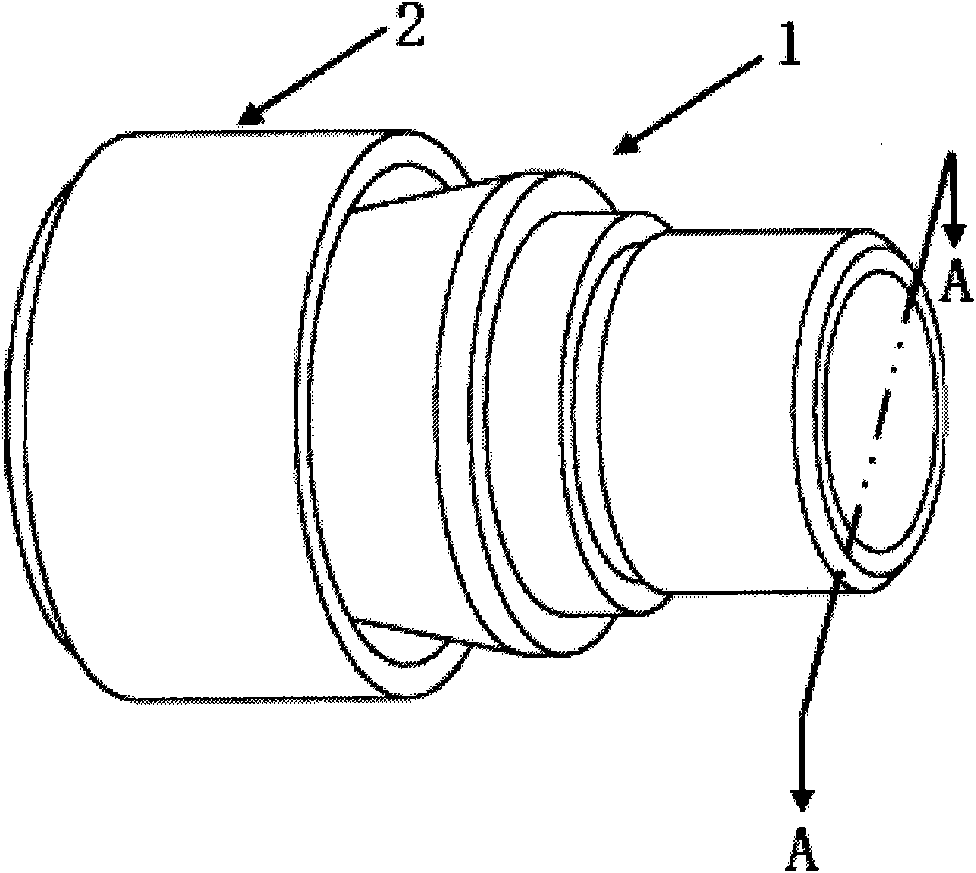

[0014] See Figure 1 to Figure 4 , Self-supporting cable sheath extrusion mold, which consists of mold core unit 1 and mold cover unit 2; 2. Fix the clamping part 13, the rear end has a fixing part 14, the fixing part 14 is provided with a thread, the end of the fixing part 14 has a chamfer 15, and the core unit 1 has a core cavity 16 inside; 11 is provided with a hanging wire hole 111, and the cable core mold core column 12 is provided with a mold core hole 121. The hanging wire hole 111 is in communication with the mold core cavity 16, and the mold core hole 121 is in communication with the mold core cavity 16. , the mold core unit has an integrated structure; the mold cover unit 2 is composed of a discharge end 25 located at the front end and a mold cover body 24 located at the rear end. There are hanging wire sheath discharge holes 21 , outer sheath discharge hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com