Mullite whisker-mullite composite coating and preparation process thereof

A mullite whisker and composite coating technology, applied in the field of non-metallic materials, can solve the problems of difficult to obtain a dense coating, low sol solid content, coating defects, etc., and achieve excellent high-temperature oxidation resistance and raw material source. Wide range of effects with low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

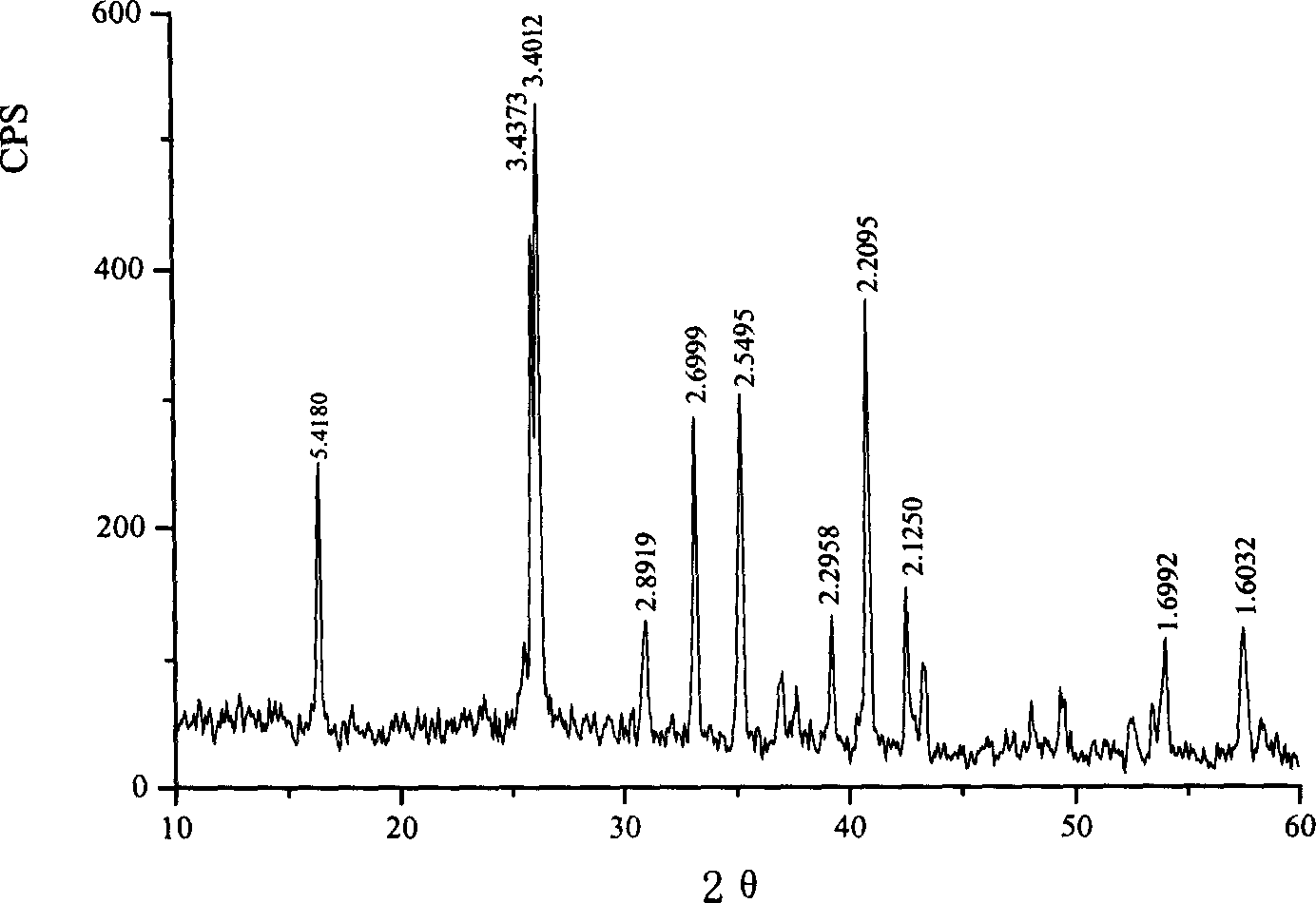

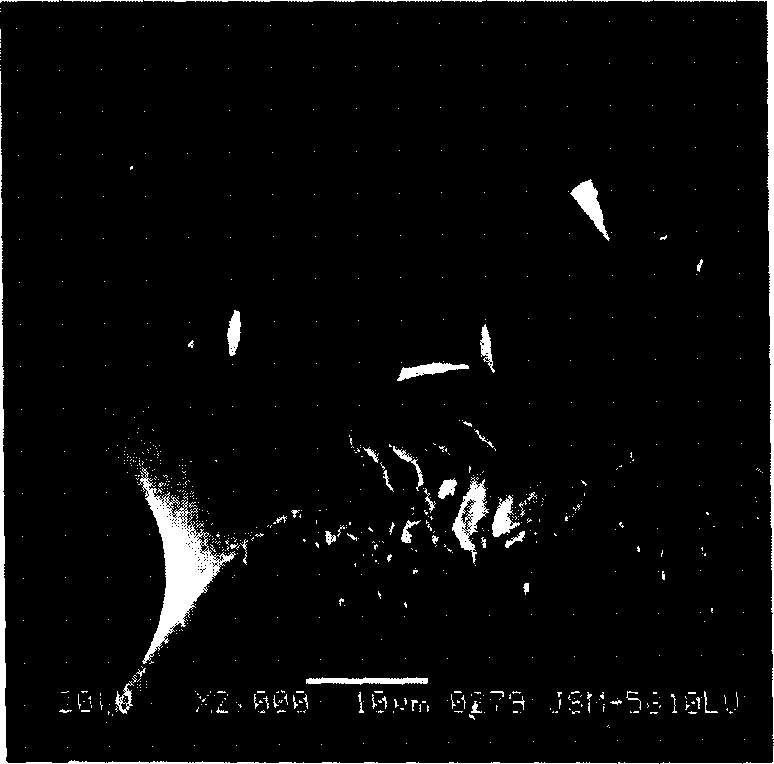

Image

Examples

Embodiment 1

[0042] (1) Preparation of mullite slurry: using ultra-fine industrial α-Al 2 o 3 Micropowder (AL 2 o 3 ≥99.6%, d 50 ≤1.0μm) and industrial quartz powder (SiO 2 ≥99.1%, d 50 ≤1.0μm) as raw material, add 5% alumina sol (pH: 6.7~7.3, Al 2 o 3 Concentration: 10±0.5%) and silica sol (pH: 6.5~8.0, SiO 2 Concentration: 30±1%) so that the proportion of alumina and silica conforms to the stoichiometric ratio of mullite (Al 2 o 3 : SiO 2 The mass ratio is 3:1), adding 6% BaF 2 (chemically pure), adjust the pH value to 7.0 to 8.0, ball mill for 10 to 24 hours according to the ratio of material: ball: water of 1:1:0.5, cast the green body into a green body, and keep the green body at 1400 to 1550°C for 1 hour ~3 hours to synthesize mullite. Crush the synthesized mullite to less than 2mm, put it into a planetary ball mill for 2 hours according to the material: ball: water ratio of 1:1.5:0.4, and make the particle size d 50 ≤1.5μm slurry.

[0043] (2) Coating coating: put recr...

Embodiment 2

[0047] (1) Preparation of mullite slurry: using kaolin as the main raw material (SiO 2 : 52±0.5%, Al 2 o 3 : 45±0.5%, d 50 ≤2.0μm), add Al according to the clay composition 2 o 3 and SiO 2 (particle size, purity with embodiment 1), adjust the ratio of the two to make it meet the mullite proportioning (Al 2 o 3 : SiO 2 The mass ratio is 3:1), adding 8% BaF 2 Do mineralizers. The process of ball milling, molding, sintering and preparing mullite slurry is the same as in Example 1.

[0048] (2) Coating: Vacuum-coat recrystallized silicon carbide with SiO 2 Sol (pH: 6.5~8.0, SiO 2 Content: 10±1%) and Al 2 o 3 Sol (same as embodiment 1), repeat 3 times. Vacuum-coat mullite slurry and dry at 70-80°C. The two-step coating process can be repeated 3 times depending on the specific situation to ensure the thickness of the coating. The coated material is sintered in air at 1100-1400° C. (same as Example 1).

[0049] In this example, the steps of coating the sealing layer ...

Embodiment 3

[0051] (1) Preparation of mullite slurry: industrial fused mullite and its mass 5% BaF 2 , 5% AlF 3 In the planetary ball mill ball mill, prepared into mullite slurry (mullite particles d 50 = 1.5 μm).

[0052] (2) Coating coating: vacuum-coat SiO with a silicon nitride bonded silicon carbide material with a porosity of 11% 2 Sol, drying (same as embodiment 2). Vacuum coated Al 2 o 3 Sol, drying (with embodiment 1). Vacuum coating mullite slurry, drying (same as embodiment 2), ensures the compactness of coating. Sintering in air at 1100-1400°C (same as Example 1).

[0053] In this example, the steps of coating the sealing layer and densifying the coating are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com