Preparation method of hollow spherical barium-strontium-titanate powder material

A technology of barium strontium titanate and powder material is applied in the field of preparation of monodisperse hollow spherical barium strontium titanate powder, which can solve the problems of easy agglomeration of powder, complicated process and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

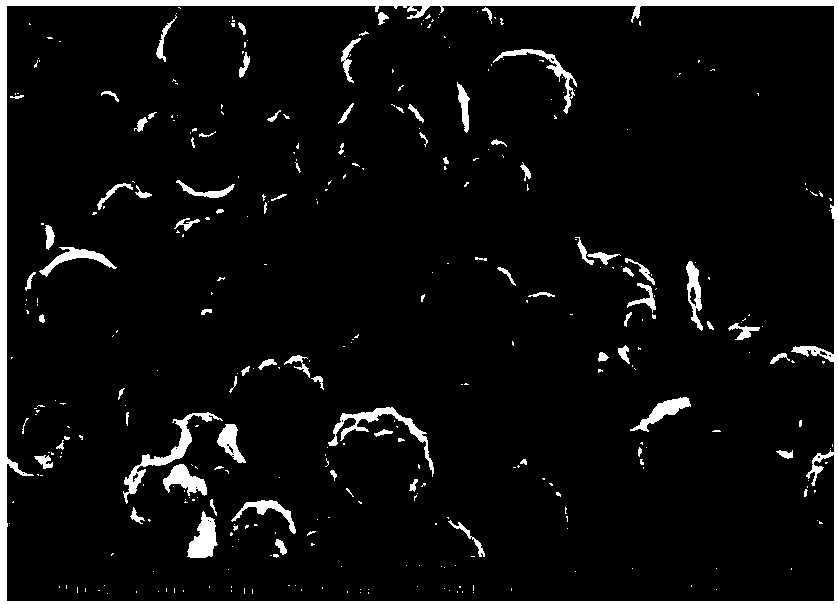

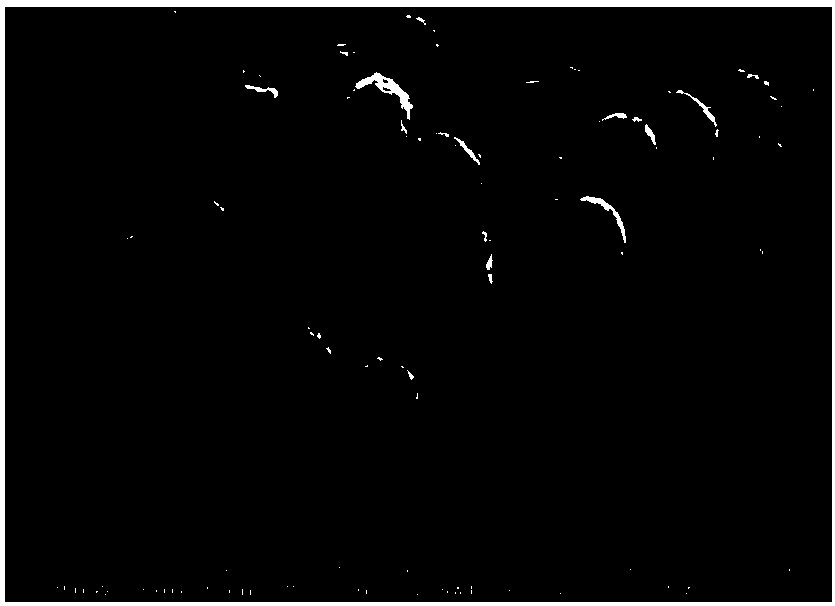

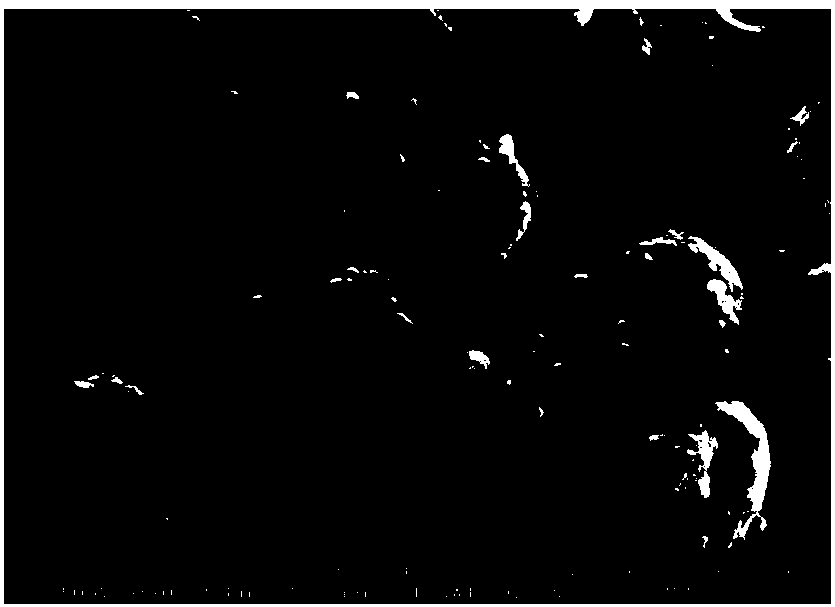

Image

Examples

Embodiment 1

[0033] This example is a method for preparing hollow spherical barium strontium titanate by using a hard template method. The atomic composition is Ba 0.6 Sr 0.4 TiO 3 Taking barium strontium titanate as an example, the spherical carbon sphere template is first prepared by hydrothermal method, and then the metal precursor solution containing Ti, Ba and Sr elements is added dropwise on the surface of the carbon sphere, and the C@BSTO composite is obtained by in situ hydrolysis reaction of the surface. microspheres, the central carbon core is removed by high-temperature calcination, and the hollow spherical Ba of cubic perovskite phase is obtained 0.6 Sr 0.4 TiO 3 Powder.

[0034] The specific implementation steps are as follows:

[0035] Step 1: Preparation of monodisperse carbon spheres by hydrothermal method. At room temperature, dissolve 9 g of analytically pure anhydrous glucose powder in 50 mL of deionized water, stir to form a glucose solution, and then add cetyl a...

Embodiment 2

[0052] This example is a method for preparing hollow spherical barium strontium titanate by using a hard template method. The atomic composition is Ba 0.6 Sr 0.4 TiO 3 Take barium strontium titanate as an example. First, the spherical carbon sphere template is prepared by hydrothermal method, and then the metal precursor solution containing Ti, Ba and Sr elements is added dropwise on the surface of the carbon sphere, and the C@BSTO composite is obtained by in-situ hydrolysis reaction on the surface. microspheres, the central carbon core is removed by high-temperature calcination, and the hollow spherical Ba of cubic perovskite phase is obtained 0.6 Sr 0.4 TiO 3 Powder.

[0053] The specific implementation steps are as follows:

[0054] Step 1: Preparation of monodisperse carbon spheres by hydrothermal method. At room temperature, dissolve 9 g of analytically pure anhydrous glucose powder in 50 mL of deionized water, stir to form a glucose solution, and then add cetyl am...

Embodiment 3

[0067] This example is a method for preparing hollow spherical barium strontium titanate by using a hard template method. The atomic composition is Ba 0.6 Sr 0.4 TiO 3 The strontium barium titanate was taken as an example. First, the spherical carbon sphere template was prepared by hydrothermal method, and then the metal precursor solution containing Ti, Ba and Sr elements was added dropwise on the surface of the carbon sphere, and the C@BSTO composite was obtained by in situ hydrolysis reaction of the surface. microspheres, the central carbon core is removed by high-temperature calcination, and the hollow spherical Ba of cubic perovskite phase is obtained 1-x Sr x TiO 3 Powder.

[0068] The specific implementation steps are as follows:

[0069] Step 1: Preparation of monodisperse carbon spheres by hydrothermal method. At room temperature, dissolve 9 g of analytically pure anhydrous glucose powder in 50 mL of deionized water, stir to form a glucose solution, and then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com