Design method of two-sided different effect digital jacquard dress fabric

A design method and fabric technology, applied in pattern design devices, textiles, textiles and papermaking, etc., can solve problems such as poor comfort and aesthetics, complex processing procedures, and detachment of fabrics, and achieve unique product styles, rich varieties, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

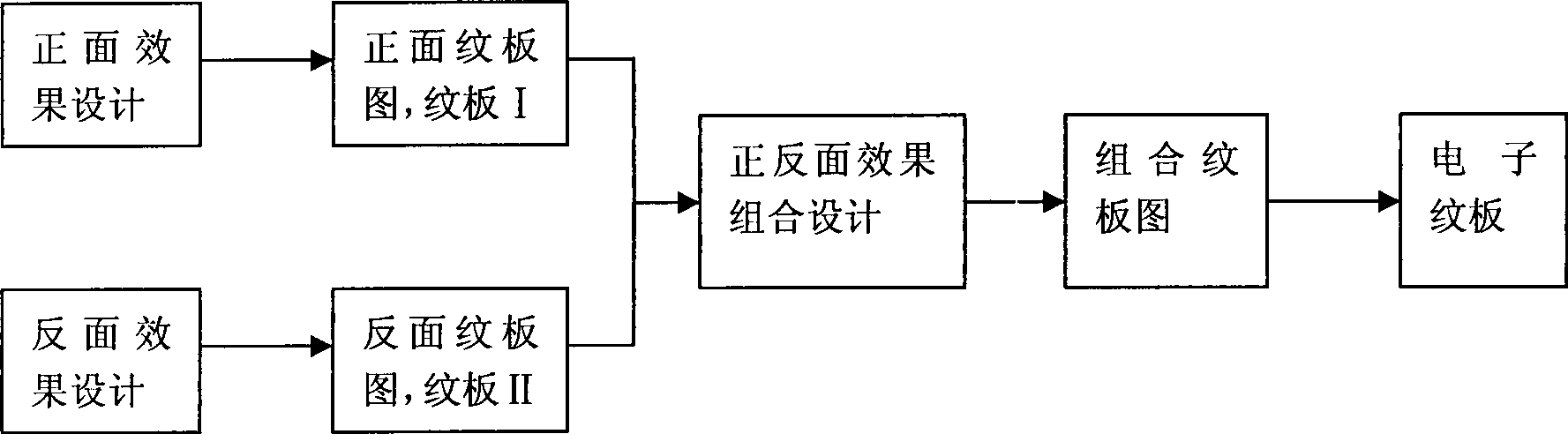

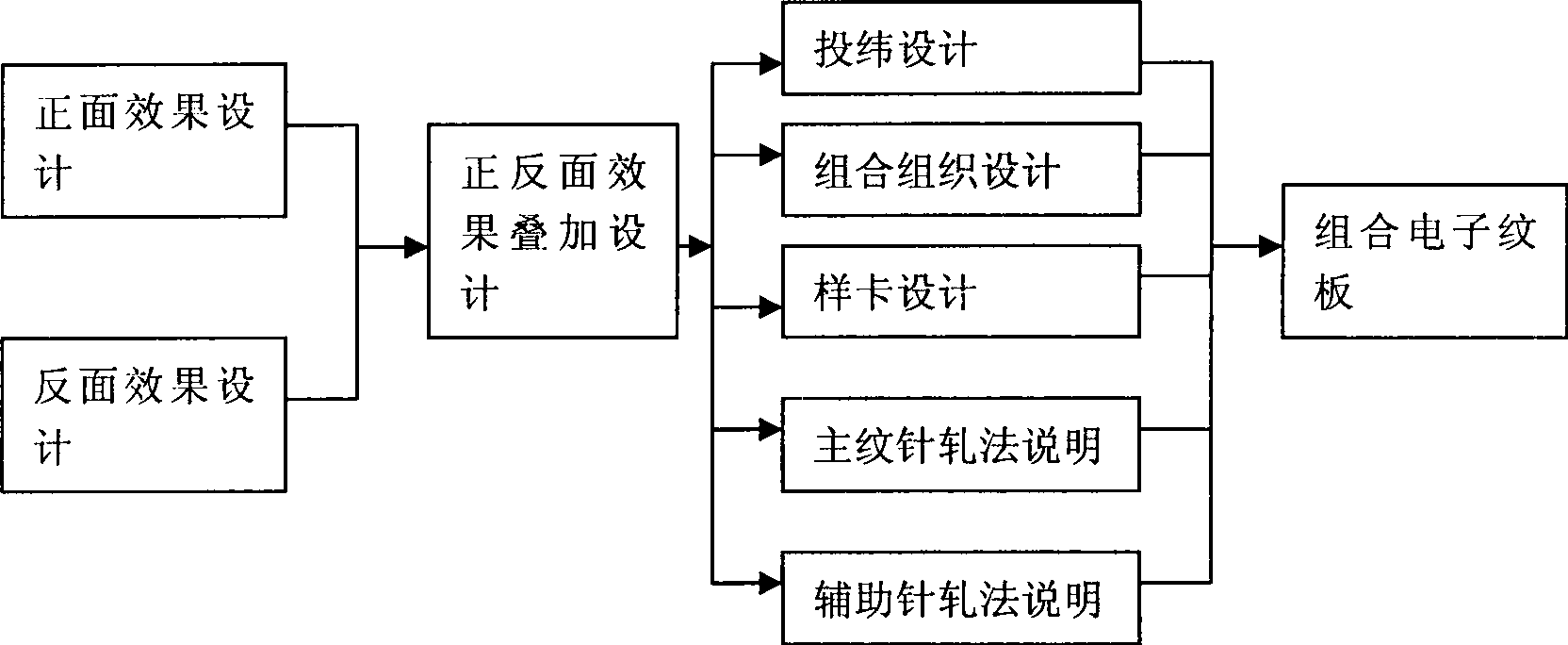

Method used

Image

Examples

Embodiment 1

[0039] Two sets of wefts of combed JC40S cotton and 150D polyester filament are interwoven with the same two sets of 120D glossy polyester warp, where surface weft: inner weft = 1:1.

[0040] In the choice of patterns, two completely different styles of patterns were selected, and geometric figures were used on the front (see image 3 ); the reverse adopts a delicate, relaxed and comfortable small flower pattern style (see Figure 4 ). See Table 1-1 for fabric specifications:

[0041] Table 1 Example 1 fabric specification table

[0042]

[0043] ①Pattern overlay design

[0044] According to the pattern superposition principle mentioned above, the image 3 and Figure 4 Carry out superposition of pattern, see the superimposed image Figure 5 .

[0045] front pattern ( image 3 ) corresponding to the artisan colors are 1, 2, 3, and the reverse pattern ( Figure 4 ) corresponding to 4, 5, 6, and 11 ( Figure 5 ) corresponds to the superposition of Italian color 1 in...

Embodiment 2

[0068] The warp arrangement ratio is 1:1, while the weft arrangement ratio is 2:1, and the two sets of weft raw materials for the surface weft have a strong contrast. The first weft is gold and silver silk, and the second weft is 75D / 24F glossy rayon. , the inner weft uses C-weft 21s cotton yarn. The fabric surface effect of the design is that A-weft flowers and B-weft flowers show each other, which increases the fabric surface effect of the fabric and also forms a greater contrast with the cotton yarn surface.

[0069] In terms of pattern selection, the front pattern uses an irregular peach-shaped pattern (see Figure 10 ), the reverse pattern linear pattern (see Figure 11 ). See Table 5 for fabric specifications.

[0070] Table 5 Example 2 fabric specification table

[0071]

[0072] ① Pattern superposition

[0073] Applying the principle of pattern superposition, the Figure 10 and Figure 11 Superimpose, the superimposed pattern see Figure 12 . Wherein the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com