Pigment dispersion, pigment photoresistor and preparation thereof

A pigment dispersion and pigment technology, applied in pigment slurry, opto-mechanical equipment, optics, etc., can solve the problems of pigment dispersion particle size not meeting the requirements, wide particle size distribution range, complex process, etc., and achieve color display. Improved quality, narrow particle size distribution, good colorimetric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

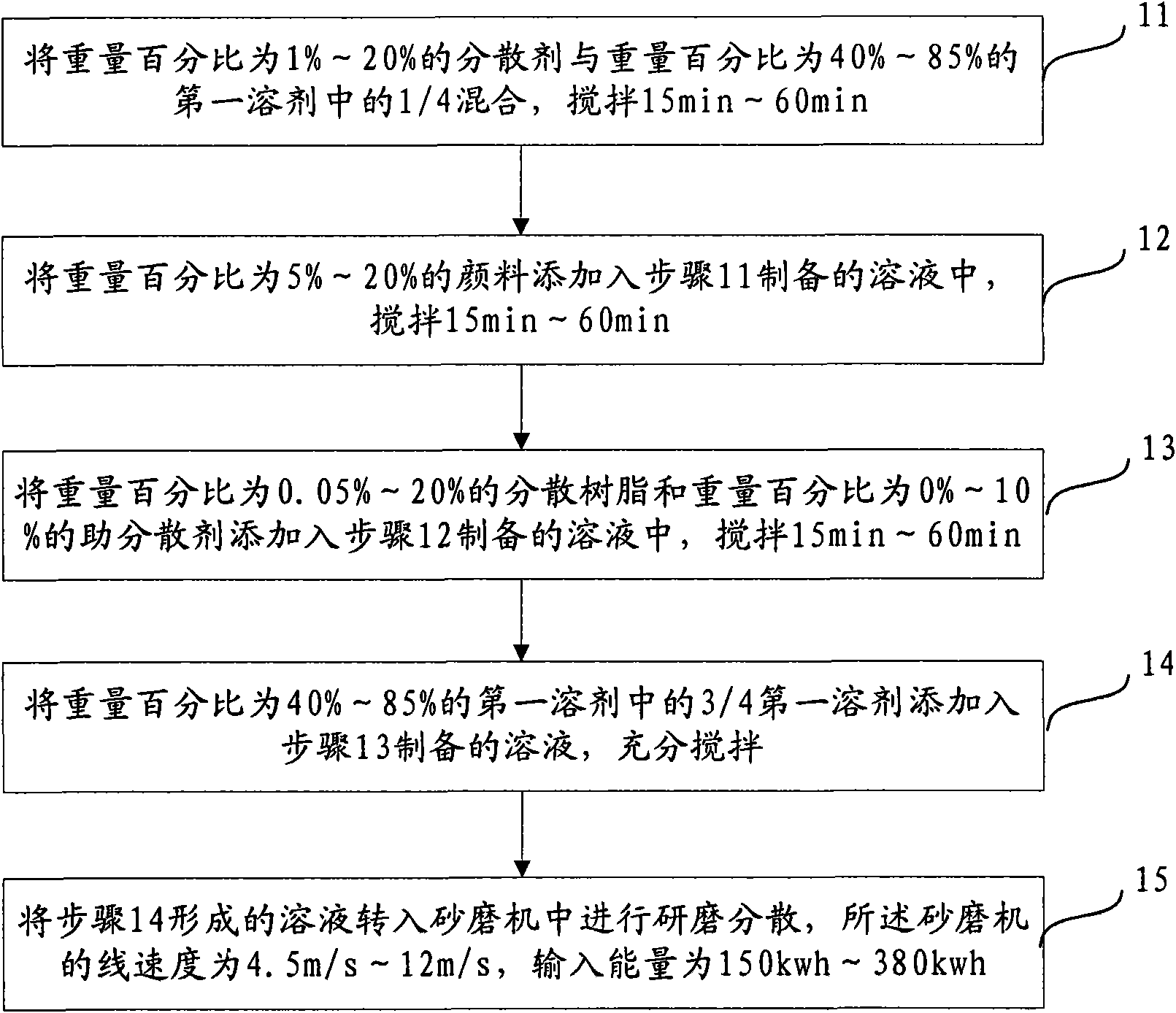

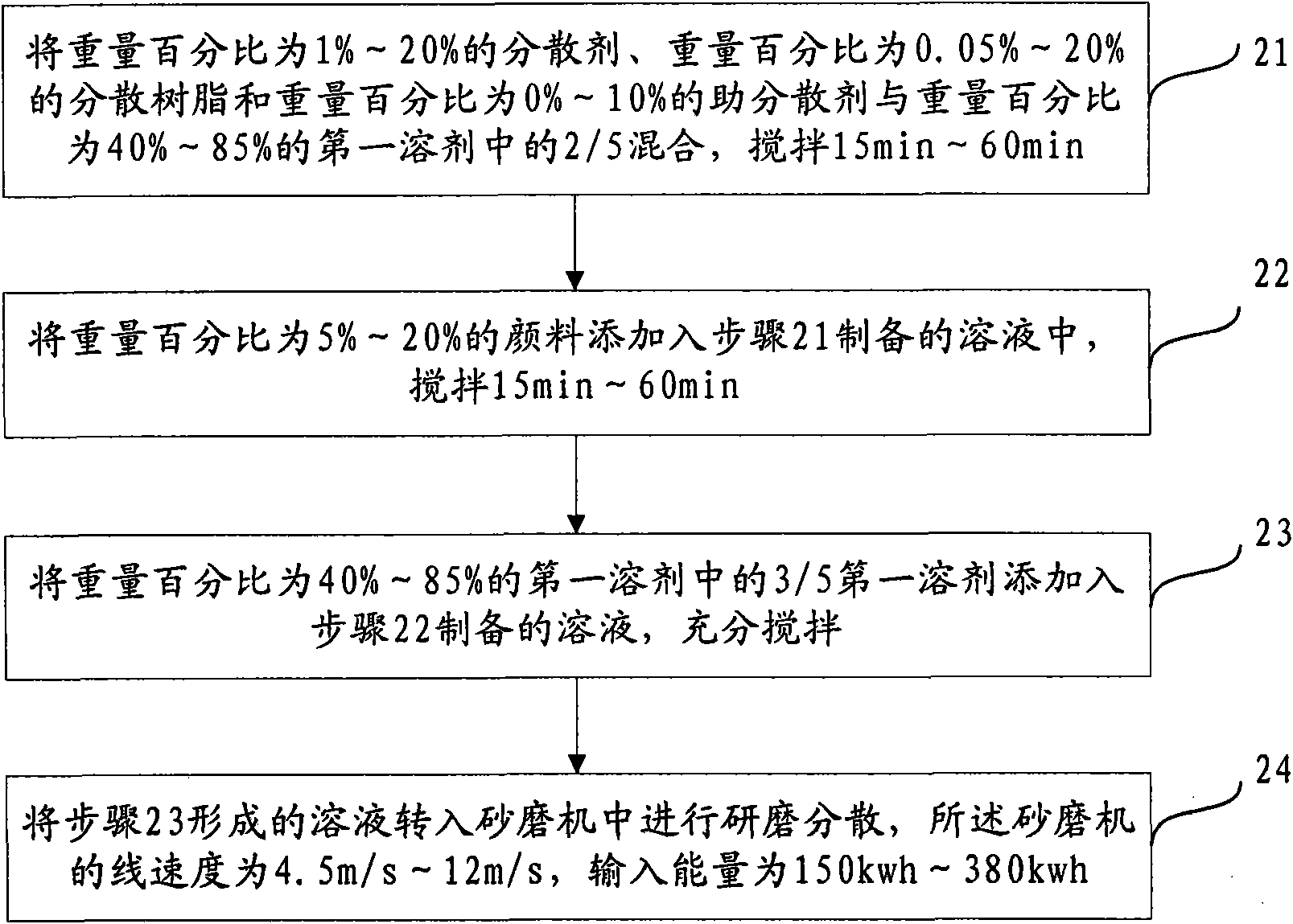

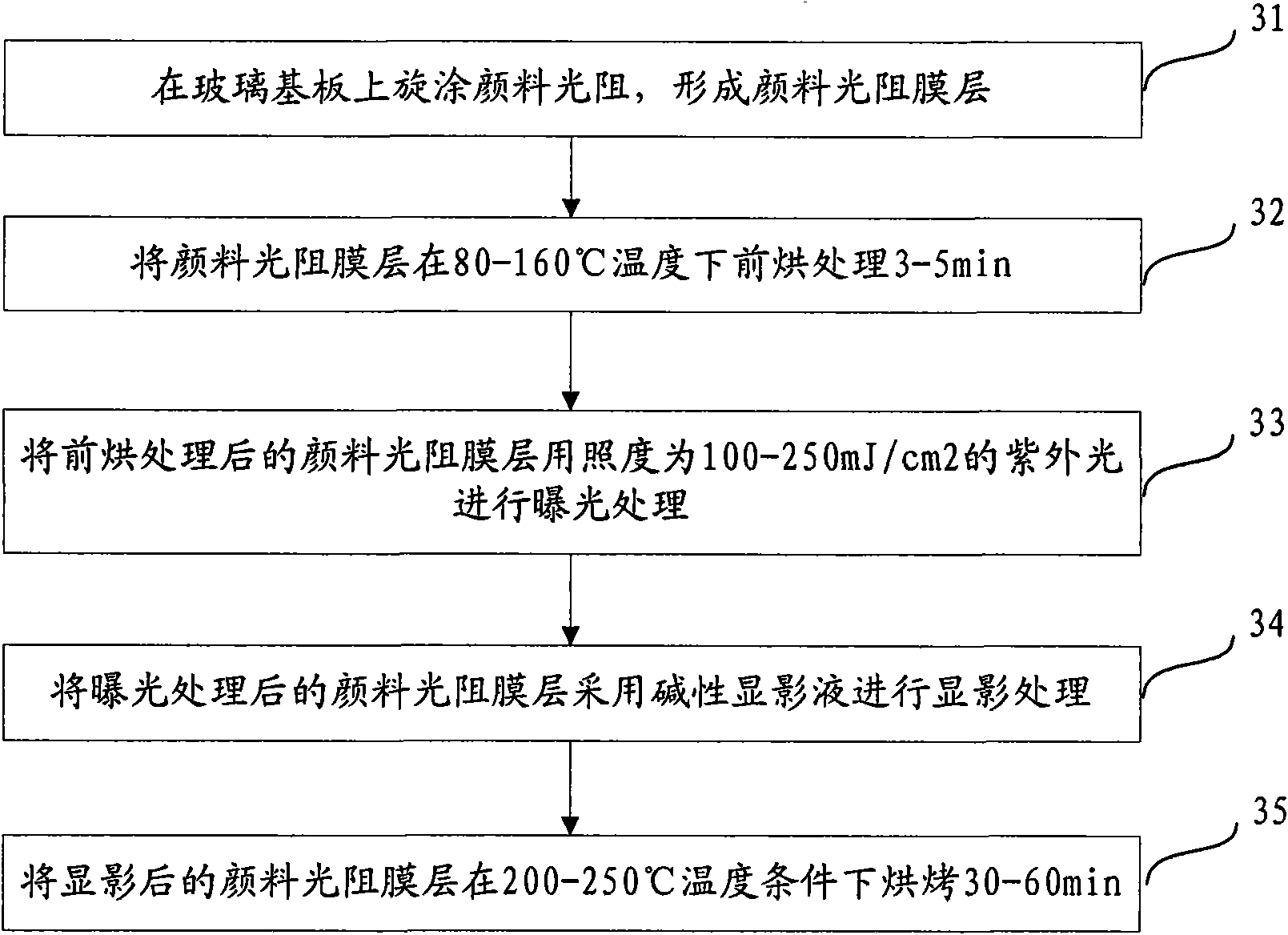

Method used

Image

Examples

no. 1 example

[0036] In this embodiment, the main components of the pigment dispersion are shown in column "1" of the embodiment in Table 1. The pigment dispersion of this embodiment comprises: the pigment that is the P.R.254 of 13.51% by weight and the P.Y.139 of 1.5% by weight, the BYK2000 dispersant that is 11.25% by weight, the SYNERGIST2105 auxiliary dispersant that is 1.2% by weight, A dispersion resin mixed with 6% by weight of ACAZ 200 and 3% by weight of CN2284, and a first solvent mixed with 60.54% by weight of PMA and 3% by weight of n-BuOH.

[0037] After testing, the particle size (average particle diameter) of the pigment dispersion in this embodiment is 16.14nm, the viscosity is 4.9cP, and the storage stability is high.

[0038] The second embodiment of pigment dispersion

[0039] In this embodiment, the main components of the pigment dispersion are shown in the "two" column of the embodiment in Table 1. The pigment dispersion of this embodiment comprises: the pigment that ...

no. 4 example

[0045] In this embodiment, the main components of the pigment dispersion are shown in column "Four" of the embodiment in Table 1. The pigment dispersion of this embodiment comprises: the P.R.254 that is 13.51% by weight and the P.Y.139 mixed pigment that is 1.5% by weight, the BYK2000 dispersant that is 11.25% by weight, the SYNERGIST2105 auxiliary dispersant that is 1.27% by weight, 4.5% by weight of Joncry1611 dispersion resin, and 67.97% by weight of PMA first solvent.

[0046] After testing, the particle size (average particle diameter) of the pigment dispersion in this embodiment is 17.5nm, the viscosity is 5.0cP, and the storage stability is high.

no. 5 example

[0048] In this embodiment, the main components of the pigment dispersion are shown in column "V" of the embodiment in Table 1. The pigment dispersion of this embodiment comprises: the P.R.254 that is 13.51% by weight and the P.Y.139 mixed pigment that is 1.5% by weight, the BYK2000 dispersant that is 11.25% by weight, the SYNERGIST2105 auxiliary dispersant that is 1.27% by weight, A dispersion resin mixed with 6% by weight of ACAZ 200 and 1.5% by weight of CN2284, and 64.97% by weight of the first PMA solvent.

[0049] After testing, the particle size (average particle diameter) of the pigment dispersion in this embodiment is 16.5nm, the viscosity is 5.0cP, and the storage stability is high.

[0050] Further, in each embodiment of the above-mentioned pigment dispersion, the pigment may include: a red pigment or a plurality of red pigment compositions, a combination of red pigment and yellow pigment, a combination of red pigment and orange pigment, a yellow pigment and Combina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com