Colourful optical filter

A color filter, red light technology, applied in the field of color filters, can solve the problems of reducing the color saturation of liquid crystal displays, unsatisfactory red, green and blue spectral resolution, and low material utilization rate, etc., to improve the color The effect of saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

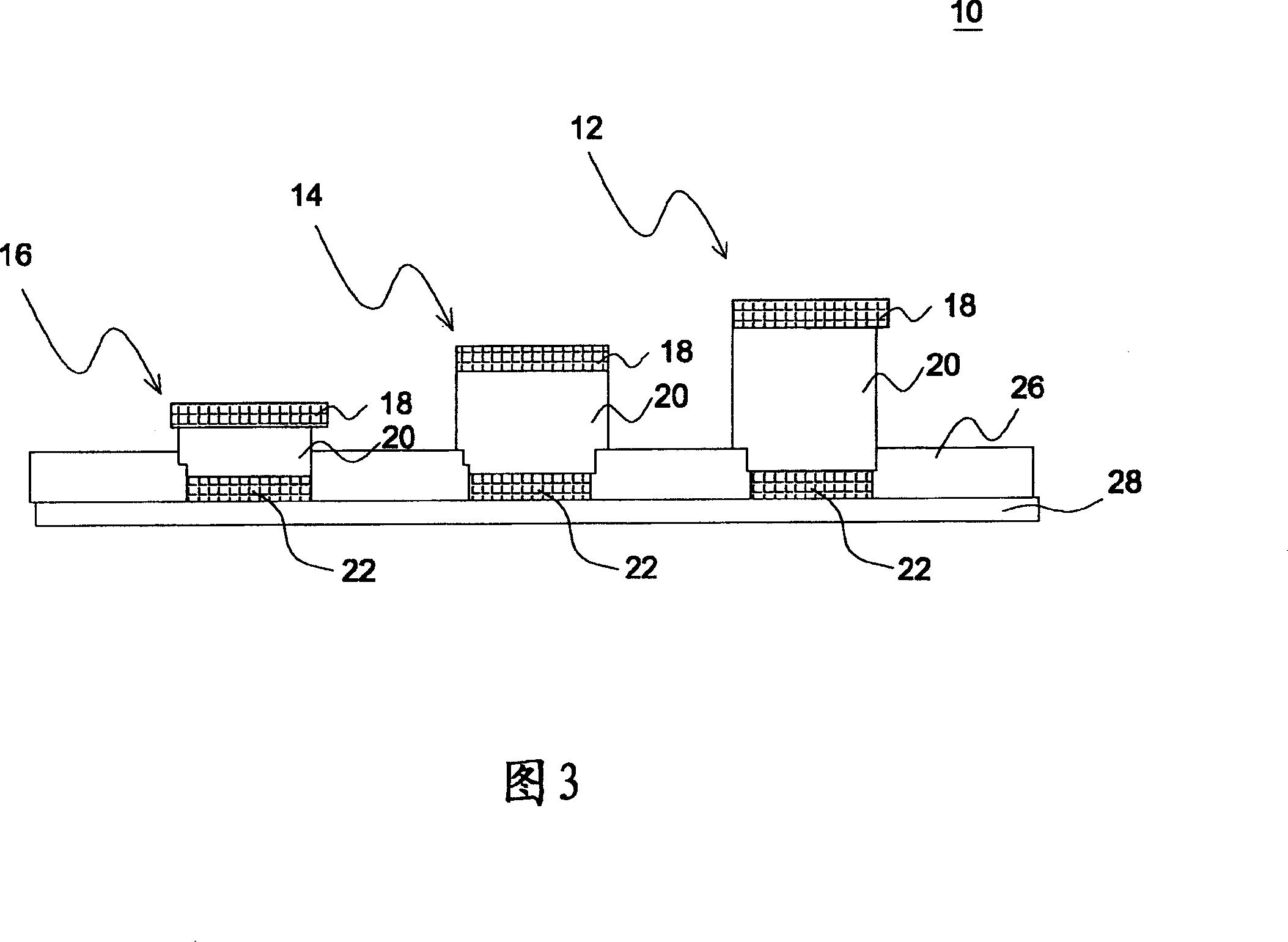

[0040] FIG. 3 is a cross-sectional structure diagram showing a color filter 10 according to an embodiment of the present invention. The color filter 10 has a red light (R) penetrating area 12, a green light (G) penetrating area 14 and a blue light (B) penetrating area 16 formed by a pixel unit corresponding to the liquid crystal display, and two adjacent penetrating areas The intervals are separated by the black matrix layer 26 formed on the transparent substrate 28 to prevent adjacent color lights from mixing with each other.

[0041] As shown in FIG. 3 , each penetrating region of the color filter 10 is composed of a three-layer film structure formed on a transparent substrate 28, including a first reflective layer 18, a gap layer 20 and a second reflective layer. 22, and the gap layer 20 is interposed between the first reflective layer 18 and the second reflective layer 22 arranged in parallel. The reflective layers 18 , 22 and the spacer layer 20 can be formed on the mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com