Bi-component sheath-core composite high-stretch fiber and preparation method thereof

A high-elastic fiber and two-component technology, applied in fiber processing, stretch spinning, filament/thread forming, etc., can solve the problems of low color fixing power, low color saturation, weak binding force, etc., and achieve good The effect of dyeing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing a two-component sheath-core composite high elastic fiber, comprising: melting the polyester component in a first screw extruder;

[0030] Melting the polyamide component in a second screw extruder;

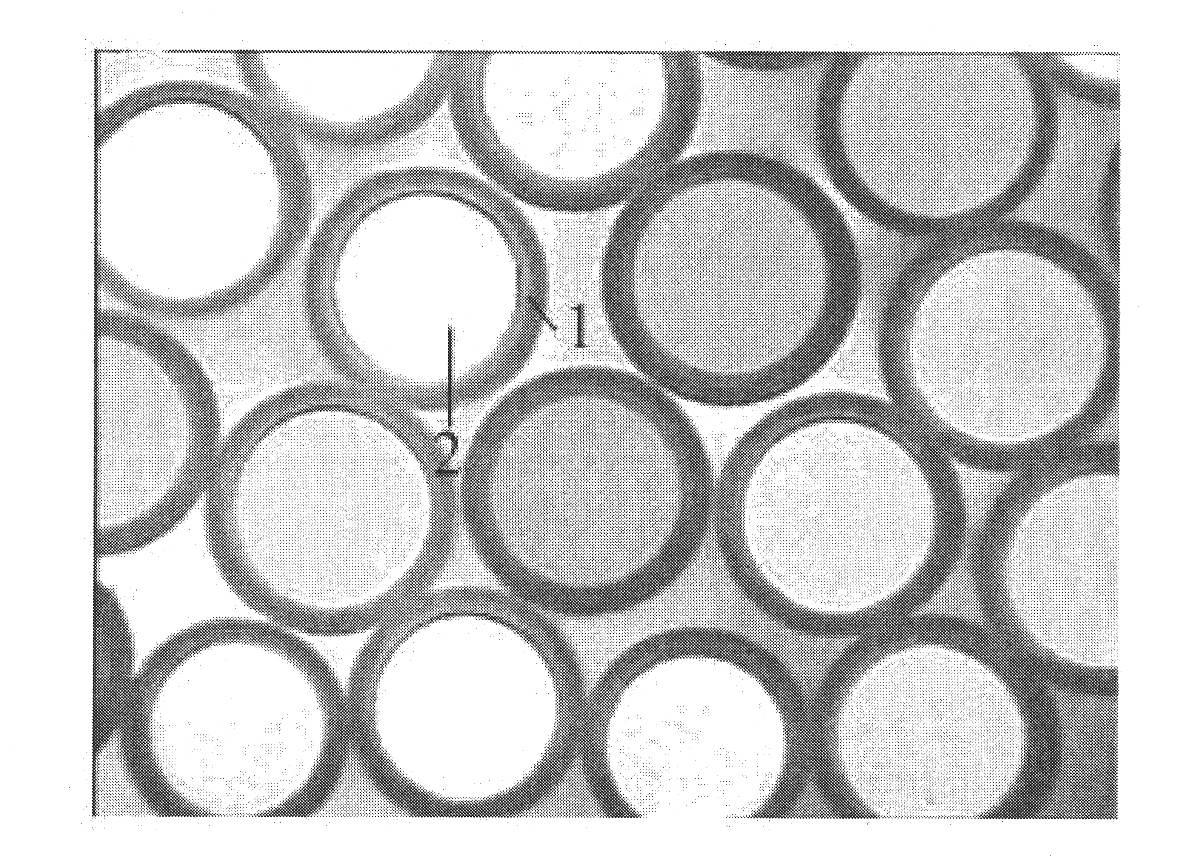

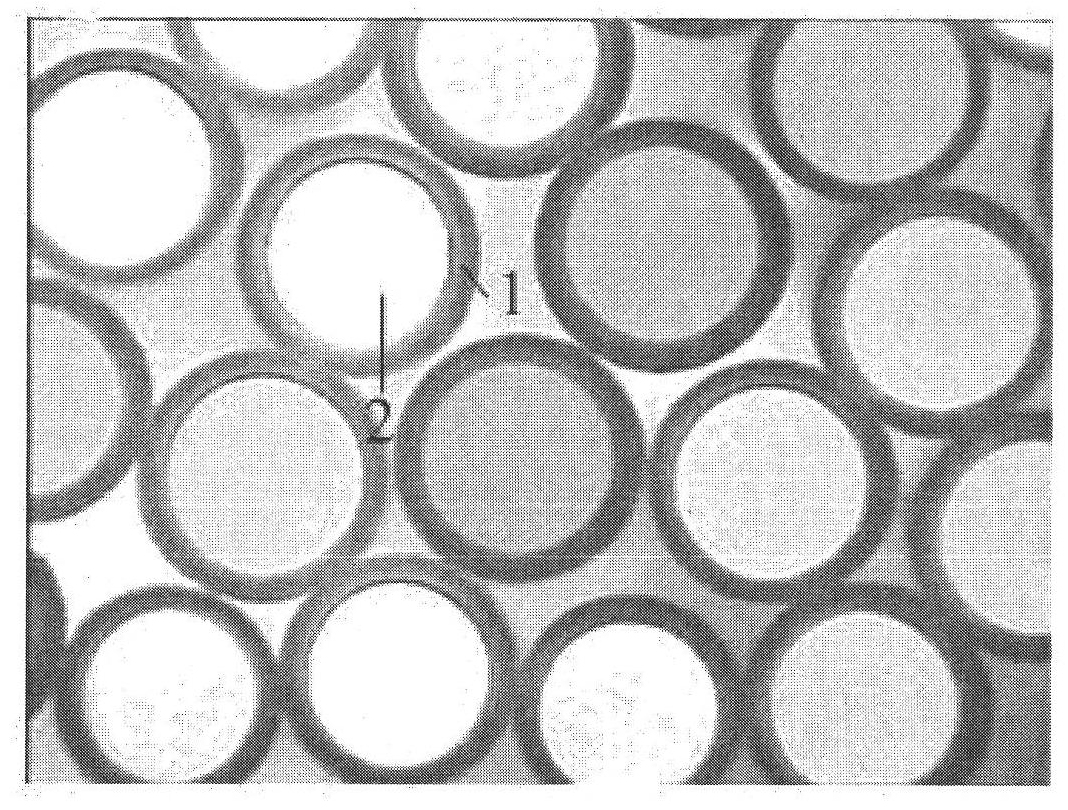

[0031] The molten product of the first screw extruder and the molten product of the second screw extruder are extruded through a spinneret to obtain nascent fibers; the polyester component is selected from cationic normal pressure dyeable polyester One or more of polytrimethylene terephthalate, polybutylene terephthalate; the polyamide component forms the sheath part of the as-spun fiber, and the polyester component forms the The inner core part of the as-spun fiber;

[0032] The as-spun fibers are cooled, oiled, drawn, and wound in sequence to obtain bicomponent sheath-core pre-oriented fibers;

[0033] The pre-oriented fiber is subjected to false-twist deformation treatment to obtain a bicomponent sheath-core co...

Embodiment 1

[0042] Take 35 pieces of PA6 slices and 65 pieces of ECDP slices and dry them in a dryer respectively. The drying temperature of ECDP slices is 135°C, and the drying temperature of PA6 slices is 80°C. The dried ECDP chips and PA6 chips were put into different extruders for melting and sprayed out through a tube-type spinneret to obtain primary fibers. The PA6 forms a sheath portion of the spun fiber, and the ECDP forms an inner core portion of the spun fiber. Then, the as-spun fiber is subjected to side blowing cooling and shaping through a cooling and blowing device, the cooling temperature is 23°C, and then oiled through an oil nozzle, the oil agent is 8wt% siloxane emulsion, and the oil content of the fiber after oiling is 1%. Then, after the fiber is drafted with a total draft ratio of 2.5, it enters the winding machine for mechanical winding and forming. The winding speed is 3200m / / min, and it is placed for 36 hours to remove the stress to obtain a two-component skin-core...

Embodiment 2~ Embodiment 4

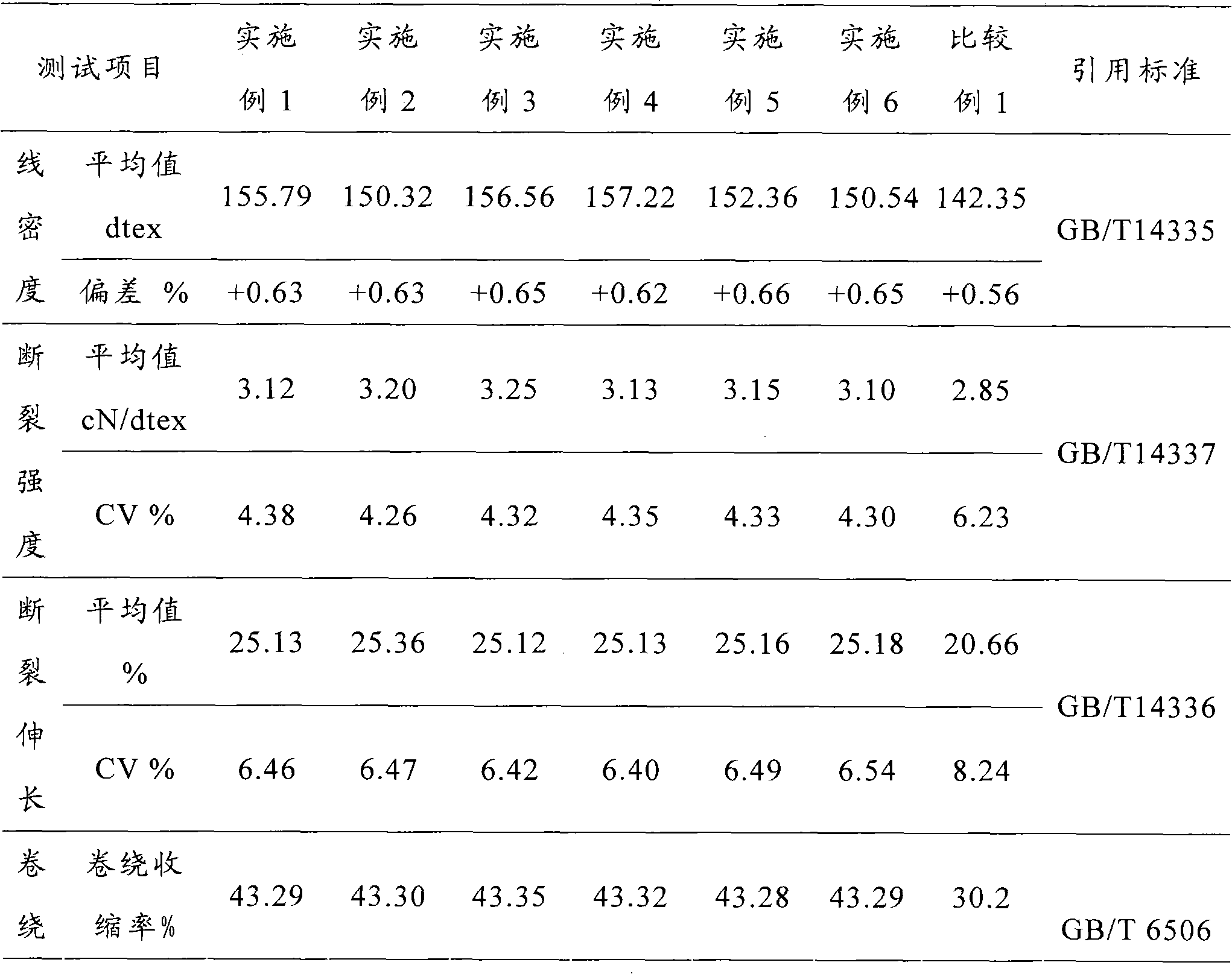

[0046] PA6 and ECDP are respectively 20: 80, 40: 60, 50: 50 by weight ratio in embodiment 2~embodiment 4, prepare two-component sheath-core type composite high-elastic fiber according to the method of embodiment 1, and use this fiber Preparation of fabrics and dyeing, measured fiber comprehensive properties and dyeing properties are shown in Examples 2 to 4 in Table 1 and Table 2, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com