Alcohol soluble notch board paper box preprinting ink

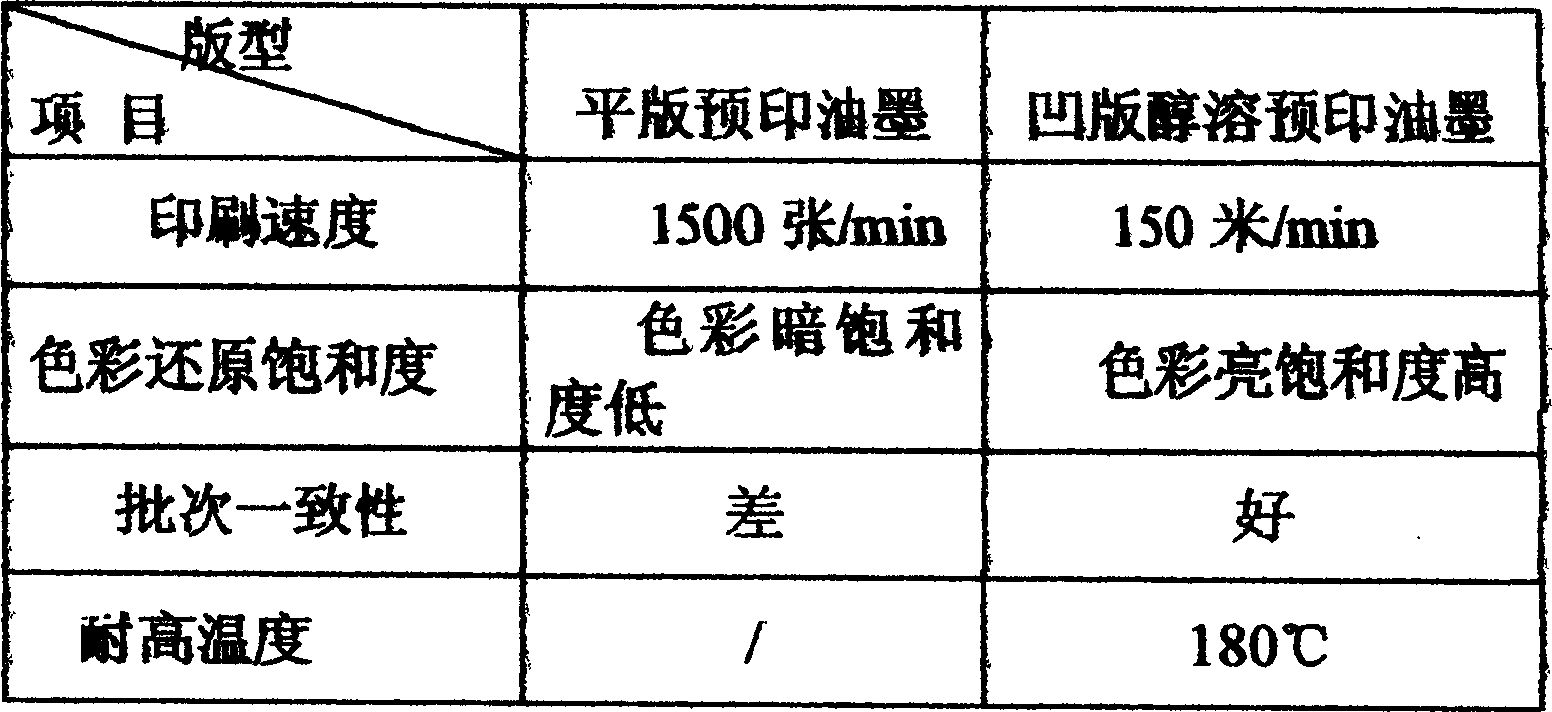

An alcohol-soluble type, carton technology, applied in the field of ink, can solve the problems of inability to guarantee batch-to-batch stability, insufficient carton patterns, and insufficient bright colors, etc., achieve excellent dot reproducibility, ensure corrugated composite and use performance, and excellent The effect of gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Nitrocellulose 7%

[0020] Thermoplastic methyl methacrylate resin 12%

[0021] Propylene Glycol Methyl Ether Acetate 8%

[0022] Dioctyl phthalate 2%

[0023] Pigment Preforms 15%

[0024] Ethyl acetate 15%

[0025] Absolute Ethanol 41%

[0026] The pigment preform is composed of 35% nitrocellulose, 5% dioctyl phthalate and 60% organic pigment powder. Organic pigment powder selects the product of the model IBXL produced by Swiss Ciba Company for use. A preparation method of alcohol-soluble gravure carton pre-printing ink, pre-dissolving nitrocellulose, thermoplastic methyl methacrylate resin and pigment preforms with ethyl acetate and absolute ethanol mixed solvent, and then adding the remaining components to fully Stir evenly, and the temperature during operation does not exceed 60°C.

Embodiment 2

[0028] Nitrocellulose 10%

[0029] Thermoplastic Acrylic 13%

[0030] Propylene Glycol Methyl Ether Acetate 4%

[0031] Dioctyl phthalate 4%

[0032] Organic pigment powder 20%

[0033] Butyl acetate 14%

[0034] Isopropanol 35%

[0035] A method for preparing alcohol-soluble gravure carton pre-printing ink. Pre-dissolve nitrocellulose, thermoplastic acrylic resin and organic pigment powder in a mixed solvent of butyl acetate and isopropanol, then add the remaining components and stir well, and operate The temperature in the process does not exceed 60°C.

Embodiment 3

[0037] Nitrocellulose 6%

[0038] Modified rosin resin 8%

[0039] Propylene glycol methyl ether acetate 6%

[0040] Dioctyl phthalate 5%

[0041] Inorganic pigment powder 18%

[0042] Isopropyl ester 20%

[0043] n-Propanol 37%

[0044] A preparation method of alcohol-soluble gravure carton pre-printing ink, pre-dissolving nitrocellulose, modified rosin resin and inorganic pigment powder with a mixed solvent of isopropyl ester and n-propanol, then adding the remaining components and fully stirring, The temperature during operation does not exceed 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com