Backlight module of display device and white light LED

The technology of a backlight module and a display device is applied to the backlight module and white LED. field, it can solve the problems such as the reduction of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

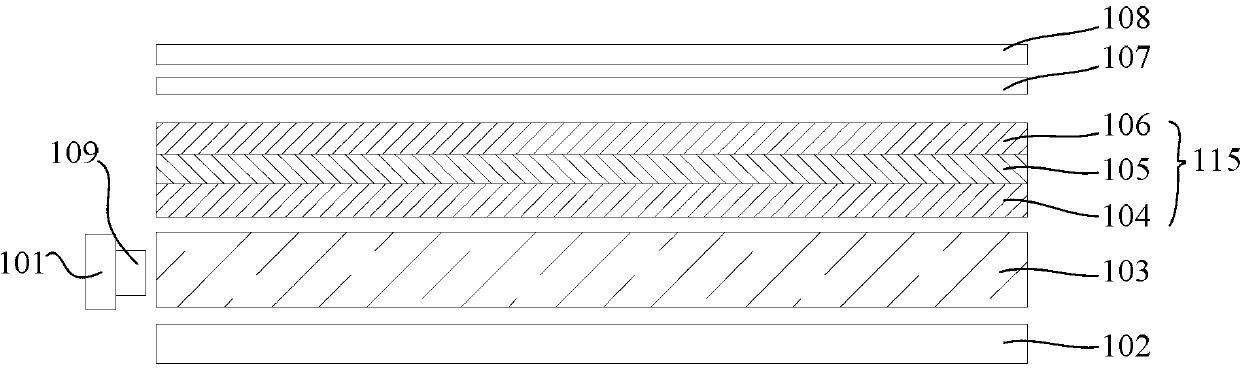

[0029] Such as figure 1 As shown, this embodiment provides a backlight module for a display device, the backlight module includes: a light bar 101 and a light guide plate 103; the light bar 101 is provided with a plurality of ultraviolet LEDs 109, and the The light incident surface is arranged opposite to the ultraviolet light LED 109; the light emitted by the ultraviolet light LED 109 includes an RGB quantum dot phosphor layer 115 in the path of the light emitted from the light exit surface of the light guide plate 103; the RGB The quantum dot phosphor layer 115 includes a red light quantum dot fluorescent film 104 , a green light quantum dot fluorescent film 105 and a blue light quantum dot fluorescent film 106 arranged in sequence. The RGB quantum dot phosphor layer 115 produces white light under the excitation of ultraviolet light emitted by the ultraviolet light LED 109, which improves the color saturation of the backlight module, and because the RGB quantum dot phosphor ...

Embodiment 2

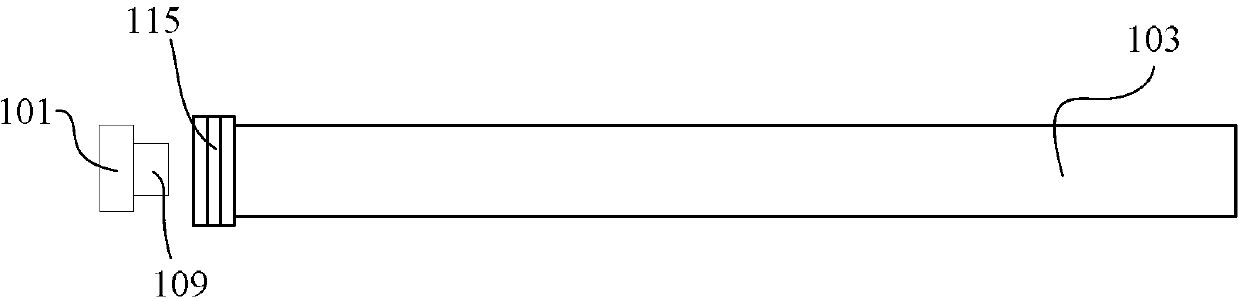

[0033] Such as figure 2 As shown, the difference from Embodiment 1 is that the RGB quantum dot phosphor layer 115 is arranged on the light incident surface of the light guide plate 103, and the light of the ultraviolet light LED 109 of the backlight module mainly enters from the light incident surface of the light guide plate 103 and then It is emitted from the light-emitting surface, so the RGB quantum dot phosphor layer 115 is provided on the light-incident surface to ensure that the light emitted from the light-emitting surface of the light guide plate is also white light. The RGB quantum dot phosphor layer is also formed by sequentially setting the red light quantum dot fluorescent film 104 , the green light quantum dot fluorescent film 105 and the blue light quantum dot fluorescent film 106 in the light irradiation direction.

Embodiment 3

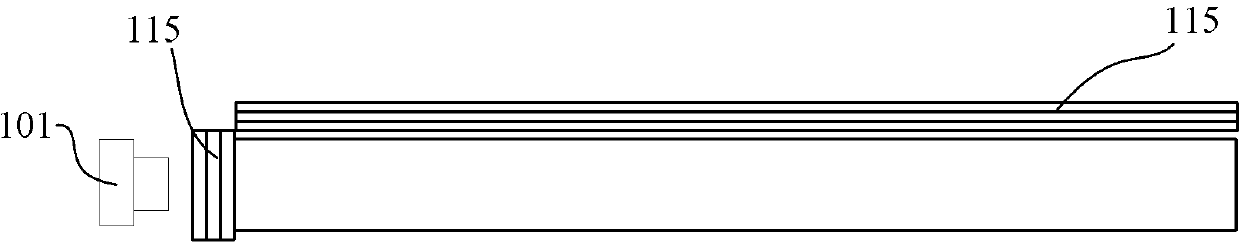

[0035] Such as image 3 As shown, the difference from Embodiment 1 and Embodiment 2 is that RGB quantum dot phosphor layers 115 are provided on both the light incident surface and the light exit surface of the light guide plate 103, thus ensuring that the light emitted from the light guide plate 103 is pure white light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com