Magic glazed tile and production method thereof

A production method and technology of magic glaze, applied in the field of architectural ceramic materials, can solve the problems of high bending strength, weak three-dimensional effect of the pattern, and single decorative effect, and achieve the effect of strong three-dimensional effect, enhanced three-dimensional effect, and clear edges of the pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A kind of production method of magic glazed tile, the steps are as follows:

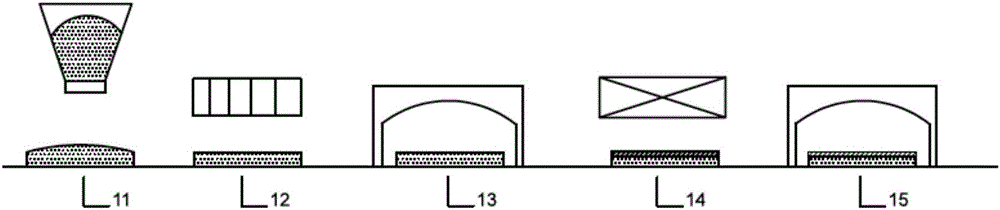

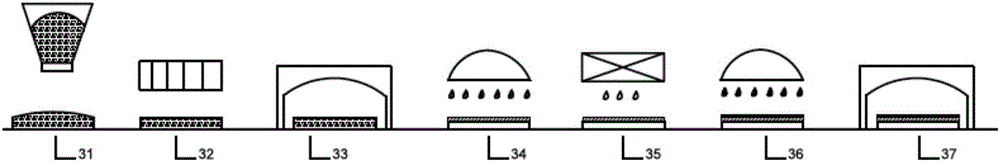

[0052] 1) Preparation of the ceramic tile body: choose ordinary glazed tile body powder, distribute the material through the material distribution device 11, press and form it through the press device 12, and form a powder base with a thickness of 10.0 mm, and send the powder base to the first firing In system 13, bisque firing is carried out at 1020° C., the firing cycle is 60 minutes, and the thickness of the ceramic tile body obtained after firing is 7.0 mm.

[0053] The chemical composition of the ordinary glazed brick body powder is: silicon dioxide 62wt%, aluminum oxide 17wt%, potassium oxide 0.5wt%, sodium oxide 0.5wt%, calcium oxide 6wt%, magnesium oxide 4wt%, trioxide Ferrous 1wt%, titanium oxide 2wt%, loss on ignition 7wt%;

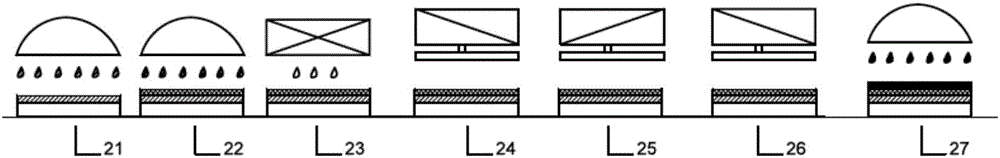

[0054] 2) Application of bottom glaze and top glaze: apply 110 g of bottom glaze on the ceramic body in step 1) through the first glaze pouring device 21 , and...

Embodiment 2

[0069] A kind of production method of magic glazed tile, the steps are as follows:

[0070] 1) Preparation of the ceramic tile body: choose ordinary glazed tile body powder, distribute the material through the material distribution device 11, press and form it through the press device 12, and form a powder base with a thickness of 15.0mm, and send the powder base to the first firing In system 13, bisque firing is carried out at 1150° C., the firing cycle is 45 minutes, and the thickness of the ceramic tile body obtained after firing is 12.0 mm.

[0071] The chemical composition of the ordinary glazed brick body powder is: silicon dioxide 55wt%, aluminum oxide 19wt%, potassium oxide 3wt%, sodium oxide 3wt%, calcium oxide 6wt%, magnesium oxide 4wt%, ferric oxide 1wt%, titanium oxide 1wt%, ignition loss 8wt%.

[0072] 2) Bottom glaze and top glaze application: 120g of bottom glaze is applied on the ceramic ceramic body through the first glazing device 21 , and 200g of top glaze ...

Embodiment 3

[0089] A kind of production method of magic glazed tile, the steps are as follows:

[0090] 1) Preparation of the ceramic tile body: choose ordinary glazed tile body powder, distribute the material through the material distribution device 11, press the press device 12 to form a powder base with a thickness of 12.0mm, and send the powder base to the firing system 13, Biscuit firing is carried out at 1030° C., the firing cycle is 58 minutes, and the thickness of the ceramic tile body obtained after firing is 9.0 mm.

[0091] 2) The raw materials used in the ordinary glazed brick body powder can be set as the powder in step 1) of Example 1.

[0092] 3) Bottom glaze and top glaze application: 114g of bottom glaze is applied on the ceramic body through the first glazing device 21 , and 196g of top glaze is applied on the bottom glaze through the second glazing device 22 .

[0093] 4) Inkjet printing: inkjet print two-dimensional planar patterns on the surface glaze in step 2) by i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com