Super-high-density LED display device and manufacturing method thereof

A display device, ultra-high-density technology, applied in the direction of electric solid-state devices, semiconductor devices, instruments, etc., can solve the problems of increased packaging costs, color drift, light decay and inconsistent voltage drift characteristics, to prevent light diffusion and improve resolution Effect of Ratio and Contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

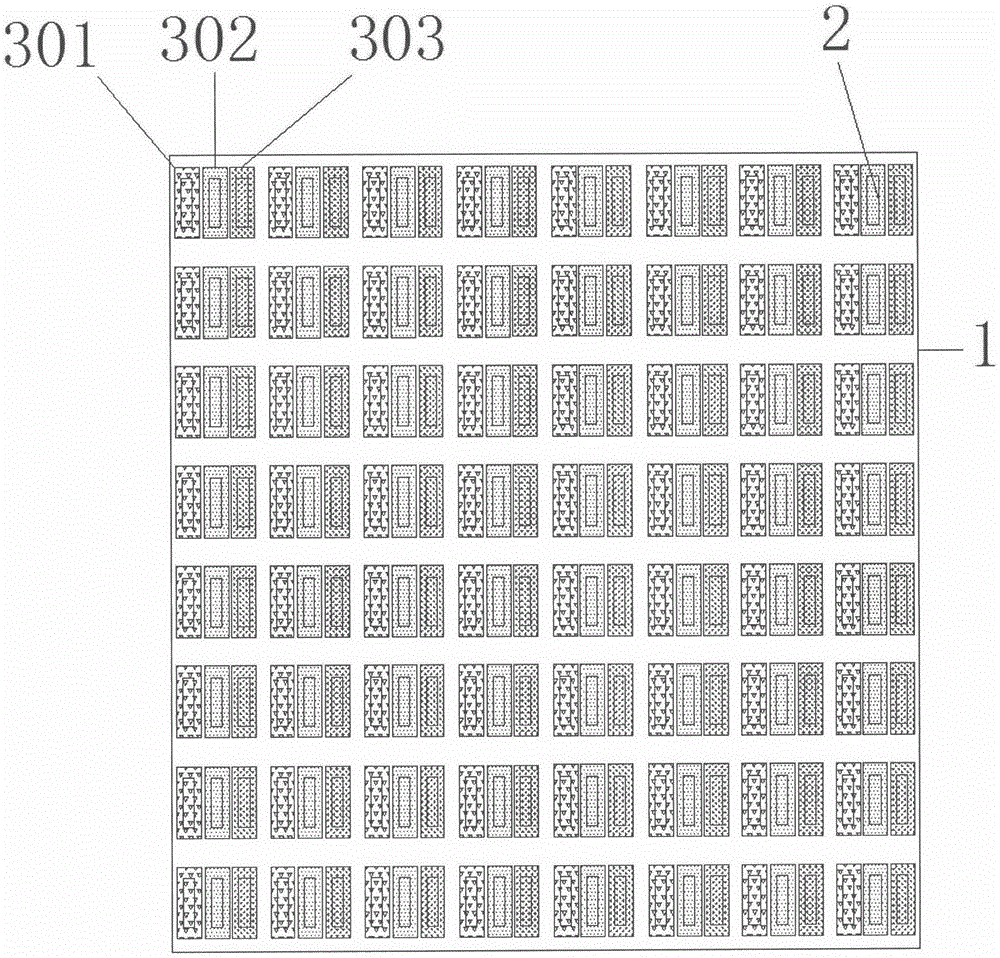

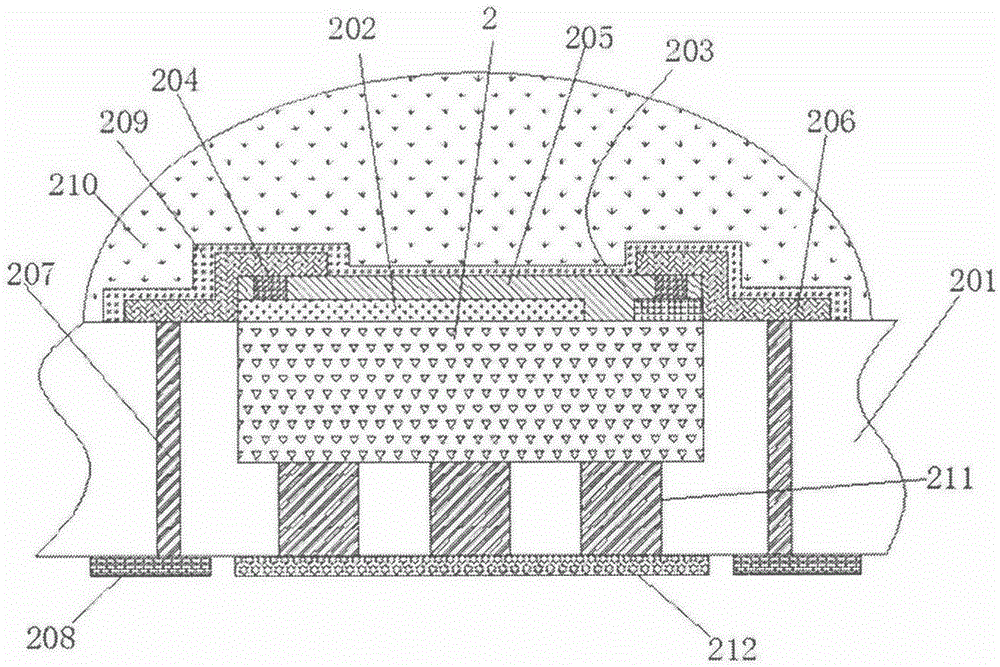

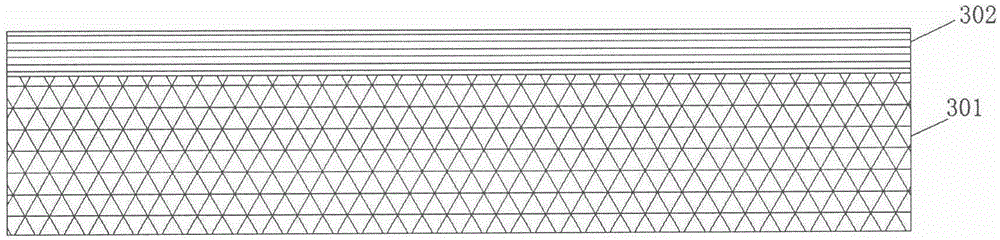

[0041] see figure 1 , which is a schematic diagram of the ultra-high-density LED display device of the present invention, including 8x8 pixels, and each pixel is composed of 3 units, wherein 1 is a substrate, 2 is an LED light-emitting chip, 301, 302 and 303 are red, 303, respectively. Green and blue light conversion materials. see figure 2 , figure 2 It is a schematic structural diagram of an LED chip in a unit in a single pixel according to Embodiment 1 of the present invention, and the LED chip array adopts a fan-out wafer-level packaging form. 201 is a molding compound, 2 is an LED chip, the surface of the LED chip is provided with a P-type ohmic contact layer 202 and an N-type ohmic contact layer 203, and the metal electrodes 204 are respectively arranged on the surfaces of the P-type ohmic contact layer 202 and the N-type ohmic contact layer 203, The passivation layer 205 is arranged between and next to the two electrodes to avoid the short circuit problem caused by...

Embodiment 2

[0064] see Figure 4 , Figure 4 It is a structural schematic diagram of a flip-chip LED chip on a substrate according to Embodiment 2 of the present invention. Figure 4 It is a schematic structural diagram of an LED chip in a unit in a single pixel according to Embodiment 2 of the present invention, and the LED chip array adopts a flip-chip packaging form. 401 is the substrate, on the surface of the LED chip 2, a P extremely high reflective layer 402 and an N extremely high reflective layer 403 are set, metal electrodes 404 are respectively set on the surface of the high reflective layer, and a passivation layer 405 is set between and next to the two metal electrodes , to avoid the short-circuit problem caused by the direct contact of the two metal electrodes, the double wiring layers 408 and 410 are arranged on the surface of the substrate 401, and the under-bump metal layer 407 is arranged on the metal wiring layer 408, and the solder ball bump 406 is used for For connec...

Embodiment 3

[0088] see Figure 5 , Figure 5 It is a schematic structural diagram of an LED chip according to Embodiment 3 of the present invention, and the LED chip array adopts a fan-out wafer-level packaging form. 201 is a molding compound, 2 is an LED chip, the surface of the LED chip is provided with a P-type ohmic contact layer 202 and an N-type ohmic contact layer 203, and the metal electrodes 204 are respectively arranged on the surfaces of the P-type ohmic contact layer 202 and the N-type ohmic contact layer 203, The passivation layer 205 is arranged between the two electrodes to avoid the short circuit problem caused by the direct contact between the two electrodes, the metal wiring layer 206 is arranged on the surface of the metal electrode, and the through hole 207 is arranged inside the molding compound for the connection between the light-emitting chip and the external driving circuit. For connection, the other side of the molding compound opposite to the light-emitting chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com