LED white lamp and encapsulation method thereof

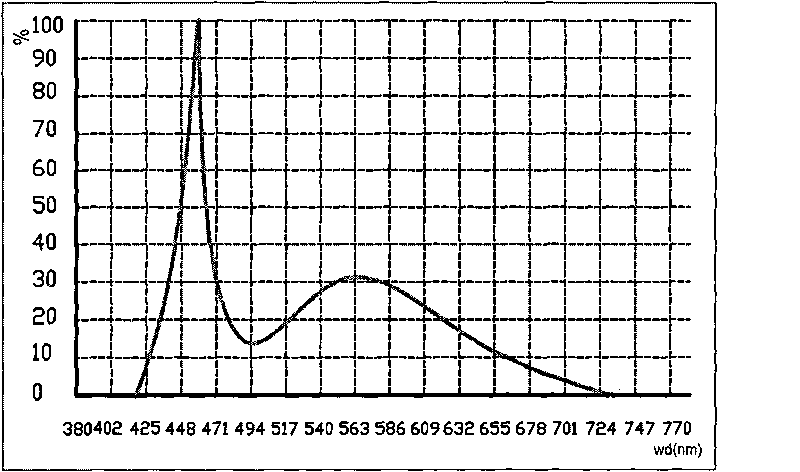

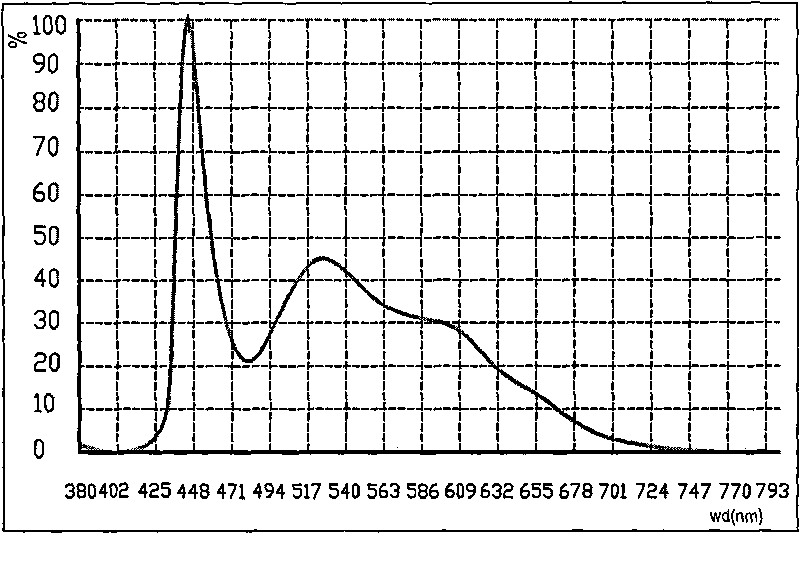

An encapsulation method and white light technology, which are applied to lighting devices, lighting device parts, lighting and heating equipment, etc., can solve the problems of insufficient color saturation, unreasonable matching, and unbalanced proportions of the picture, and achieve the color saturation of the picture. The effect of high degree and strong picture layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

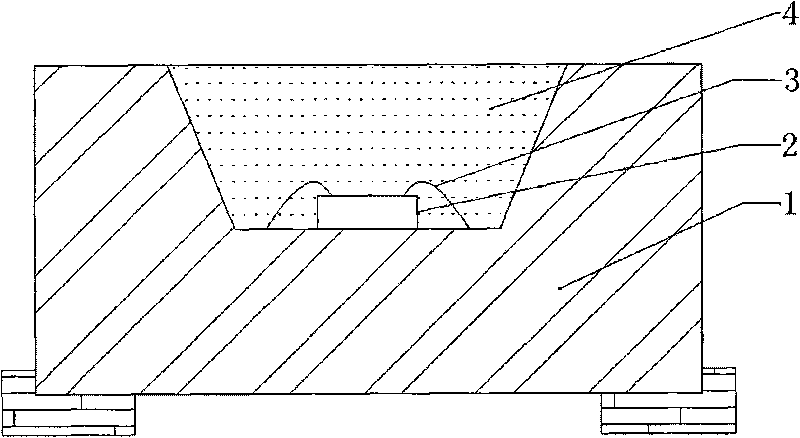

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0020] see image 3 , Figure 4 as well as Figure 5 , The LED white lamp of the present invention includes a concave receiving seat 1 and an LED blue light chip 2, and the LED blue light chip 2 is fixed in the concave receiving seat 1 by silver glue or insulating glue. The blue LED chip 2 has positive and negative electrodes, and the concave socket 1 has positive and negative electrodes. The positive and negative electrodes of the LED blue chip 2 are respectively welded to the positive and negative electrodes of the concave socket 1 with wires 3 . The surface of the LED blue chip 2 in the concave socket 1 is encapsulated with fluorescent glue 4 .

[0021] The present invention provides a LED white light packaging method comprising the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com