Biaxially oriented polyester matte precoat and preparation method thereof

A biaxially stretched polyester and pre-coated film technology, applied in polyurea/polyurethane coatings, chemical instruments and methods, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

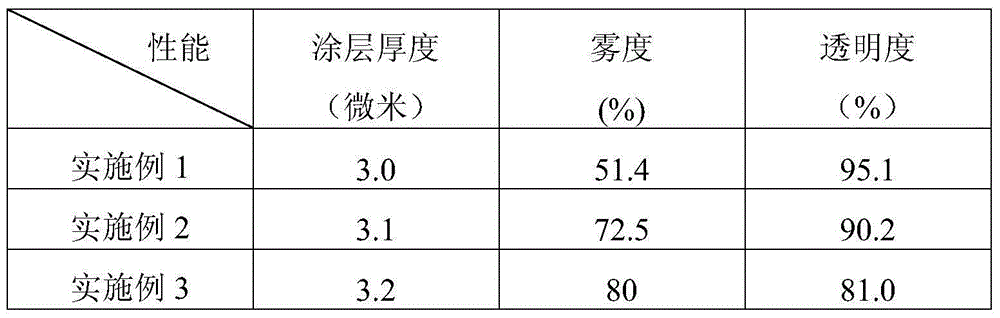

Embodiment 1

[0035] Take the biaxially oriented polyester (BOPET) matte pre-coating film with a width of 1300mm as an example to describe in detail.

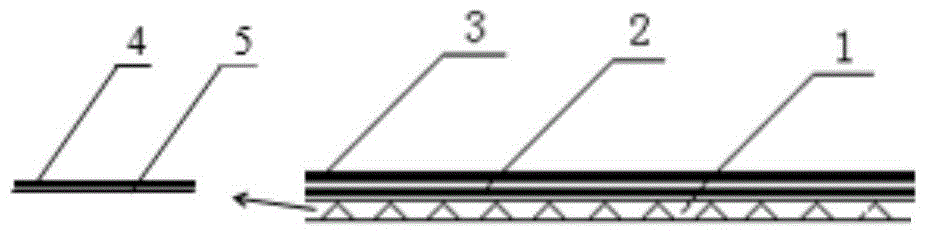

[0036] refer to figure 1 , first prepare the BOPET matt substrate (1). The substrate (1) consists of a polyester layer (4) and a matt coating (5). Wherein, the thickness of the polyester layer (4) is 12 microns, and the thickness of the matte coating (5) is 3 microns. Firstly, a biaxially oriented polyester film (4) is processed by using biaxially oriented polyester production equipment, and a layer of matte coating (5) is evenly coated on one surface thereof to obtain the substrate (1), the substrate (1) The thickness is 15 microns. 83.3 parts of aliphatic water-based polyurethane emulsion (U8001), 1.3 parts of lauryl alcohol ester, 0.3 part of polyoxypropylene glyceryl ether, 0.1 part of BYK-346, 3 parts of silica matting powder and 12 parts of HDI-IPDI composite trimer (XD803) After mixing evenly in a high-speed disperser and filterin...

Embodiment 2

[0049] Take the biaxially oriented polyester (BOPET) matte pre-coating film with a width of 1650mm as an example to describe in detail.

[0050] refer to figure 1 , first prepare the BOPET matt substrate (1). 83.2 parts of aliphatic water-based polyurethane emulsion (INCOREZ W2400), 1.2 parts of diethylene glycol monobutyl ether, 0.4 parts of ethanol, 0.2 parts of BYK-345, 5 parts of polymethylurea formaldehyde polymer powder and 10 parts of HDI trimer ( XM501) into a high-speed mixer, mixed evenly in a high-speed disperser and filtered, then coated on the surface of a commercially available bright BOPET film (specification 12μm*1670mm*12000m) by roller coating, and dried to form a BOPET matte base Material (1), its specification becomes 15μm*1670mm*12000m.

[0051] refer to figure 1 : Preparation of BOPET matte pre-coating film. The pre-coating film is formed by sequentially coating a 0.01 μm PEI intermediate layer (2) and a 25 μm composite hot-melt adhesive LDPE layer on...

Embodiment 3

[0053] Taking the biaxially oriented polyester (BOPET) matte pre-coating film with a width of 1650mm as an example, it will be described in detail.

[0054] refer to figure 1 , first prepare the BOPET matt substrate (1). 89.92 parts of solvent-based polycarbonate polyurethane dispersion (B01-7), 0.03 parts of defoamer (XPT-118), 0.05 parts of leveling agent polyether modified polydimethylsiloxane (BD-3308) , 6 parts of silica matting agent (OK520) and 4 parts of aliphatic polyisocyanate curing agent (Z4470SN) were mixed uniformly in a high-speed disperser and filtered, and then coated on a commercially available bright BOPET film (specification 12 μm) by roller coating *1670mm*12000m) surface, after drying to form a BOPET matt substrate (1), its specification becomes 15μm*1670mm*12000m.

[0055] refer to figure 1 : Preparation of BOPET matte pre-coating film. Its processing method is identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com