Transflective liquid crystal display panel and liquid crystal display

A liquid crystal display panel, transflective technology, applied in instruments, nonlinear optics, optics, etc., can solve the cumbersome manufacturing process of the transflective liquid crystal display panel and increase the preparation process of the transflective liquid crystal display panel Difficulty and other issues to achieve the effect of reducing the difficulty of the preparation process and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

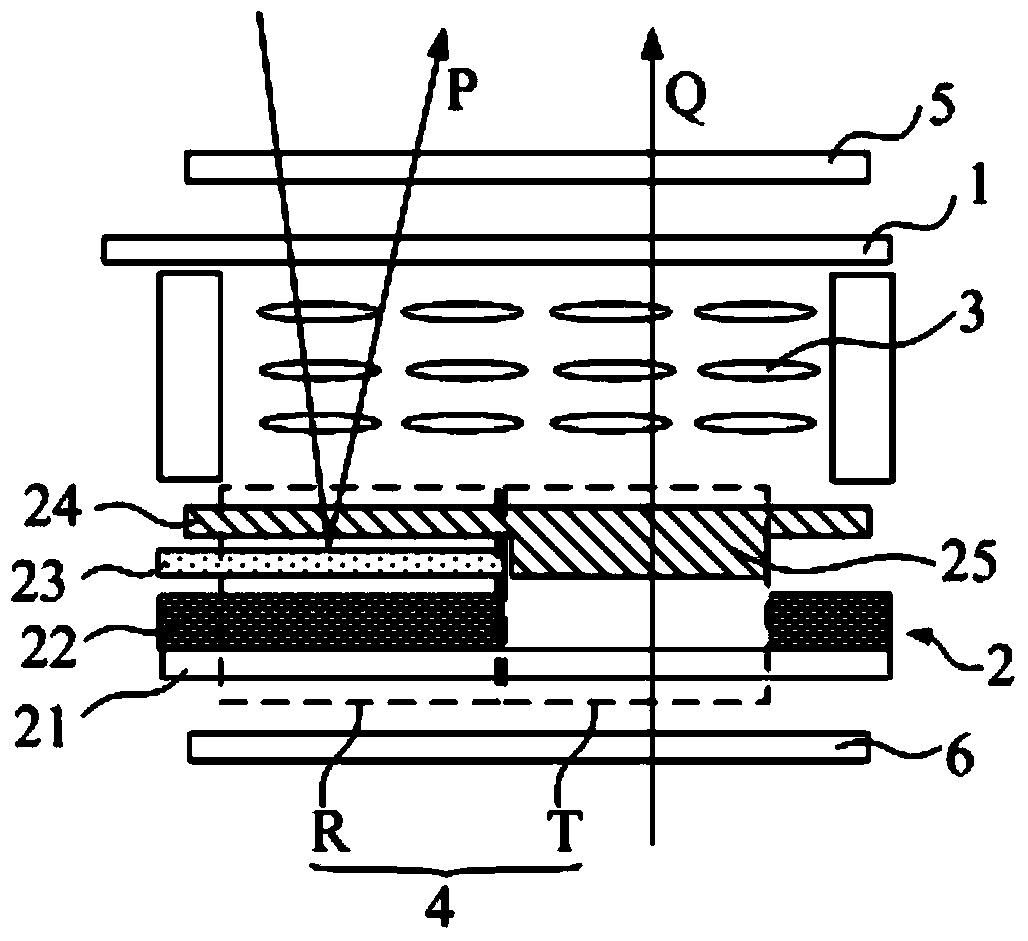

[0028] Please refer to figure 2 , the transflective liquid crystal display panel provided in this embodiment includes an upper substrate 1 and a lower substrate 2 connected to the cell, and a liquid crystal layer 3 filled between the upper substrate 1 and the lower substrate 2; wherein, the lower substrate 2 It includes a plurality of sub-pixel units 4 distributed in an array, and each sub-pixel unit 4 includes a reflective region R and a transmissive region T. Along the direction from the lower substrate 2 to the upper substrate 1, the reflective region R sequentially includes a base substrate 21 and a black matrix 22 , the reflective layer 23 and the first color filter layer 24, the transmissive region T includes the base substrate 21 and the second color filter layer 25 in sequence, and the thickness of the first color filter layer 24 is smaller than that of the second color filter layer 25 thickness. Wherein, the first color filter layer 24 and the second color filter la...

Embodiment 2

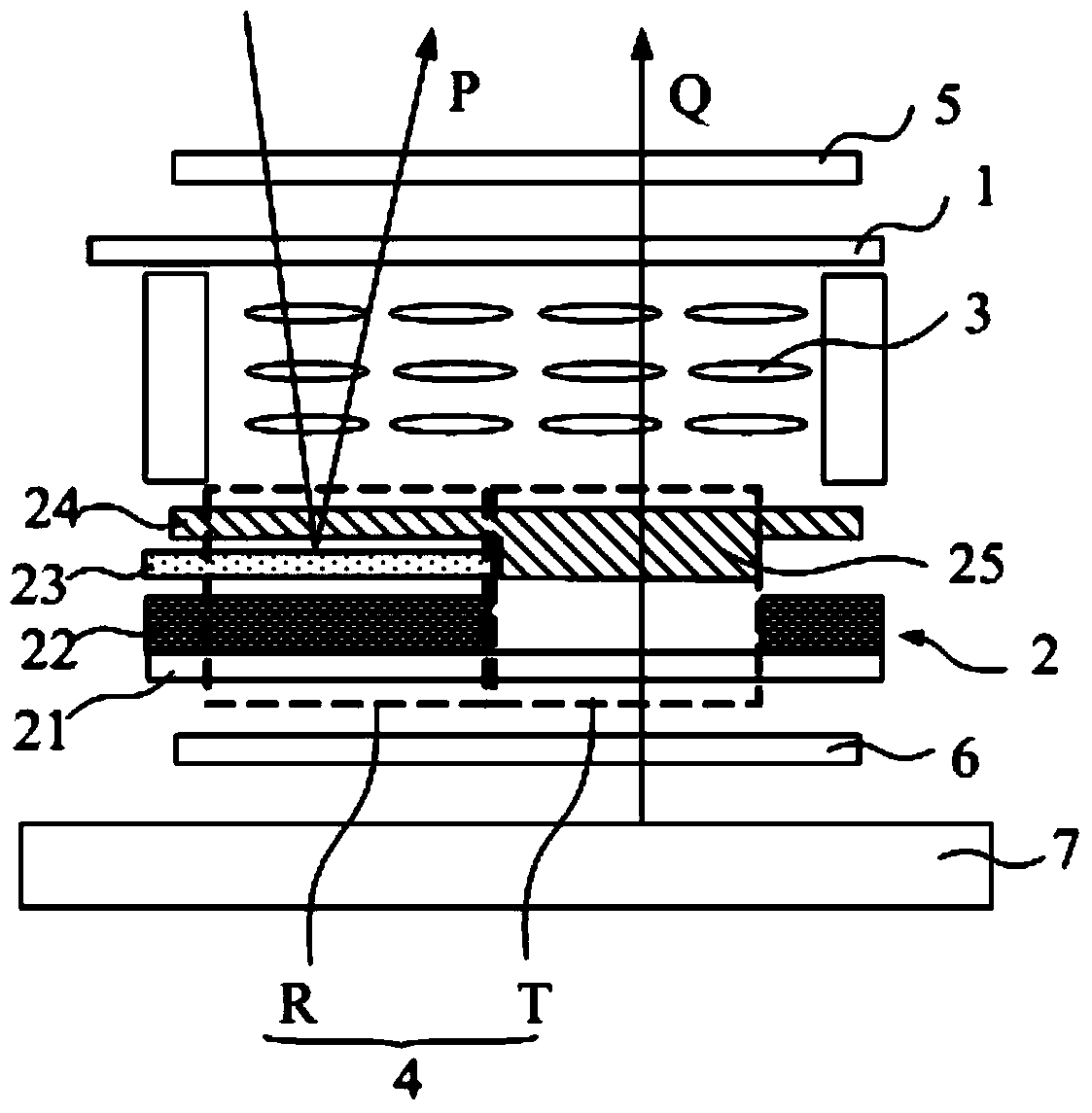

[0041] Please refer to image 3 , this embodiment provides a transflective liquid crystal display, including a backlight source 7 and the transflective liquid crystal display panel provided in the first embodiment above, wherein the backlight source 7 is located in the liquid crystal display panel and the lower substrate 2 is away from One side of the upper substrate 1.

[0042] In the transflective liquid crystal display panel provided by the first embodiment above, there is no need to set openings and transparent filters in the reflective region R of each sub-pixel unit 4, so that the color saturation of the reflective region R and the transmissive region can be improved. The color saturation of T tends to be consistent, so that the preparation process of the transflective liquid crystal display panel omits the process of setting openings and transparent filters in the reflection region R of the sub-pixel unit 4. Therefore, in the transflective liquid crystal display with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com