Trilithic and/or twin shell dome type structures and method of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

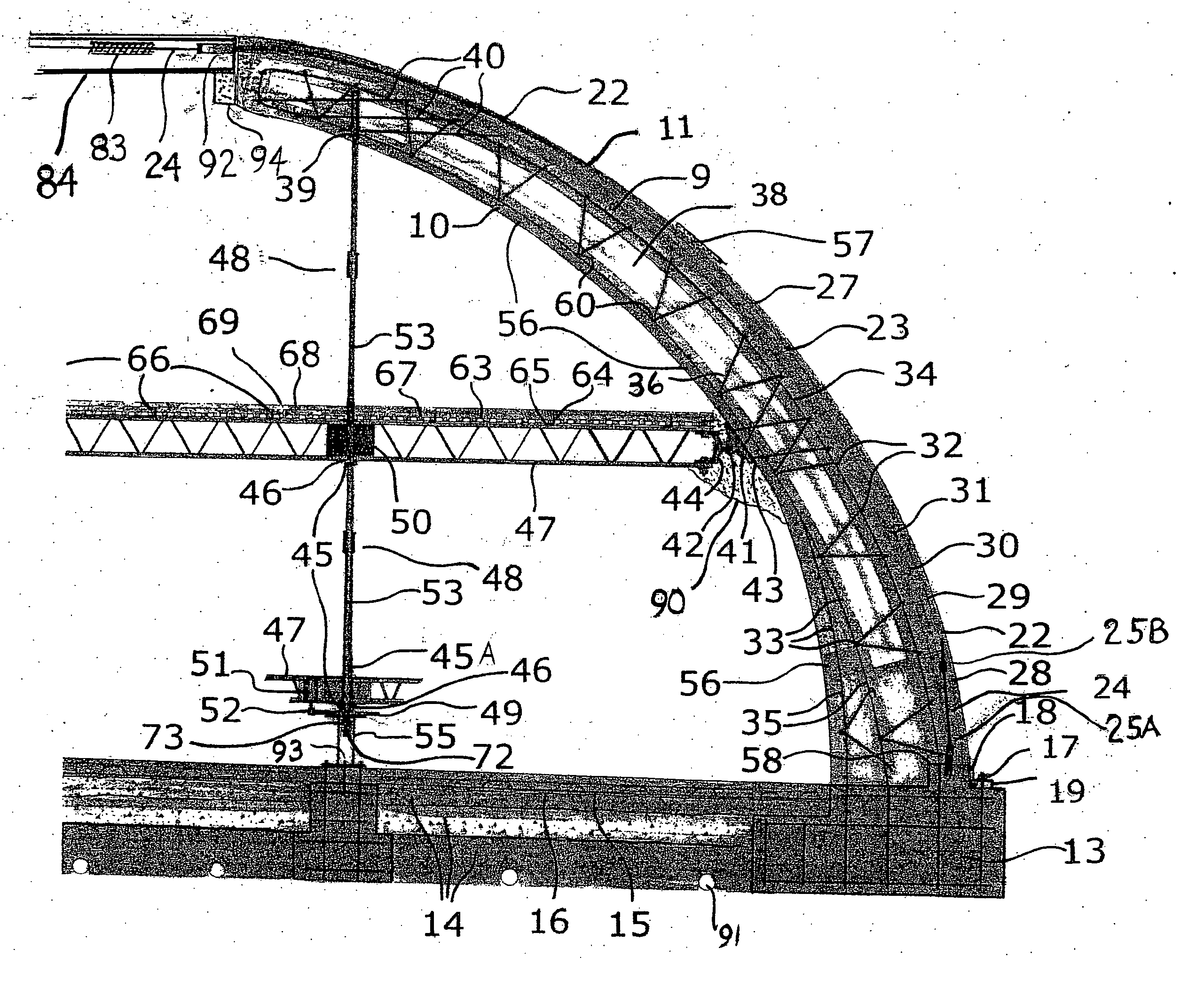

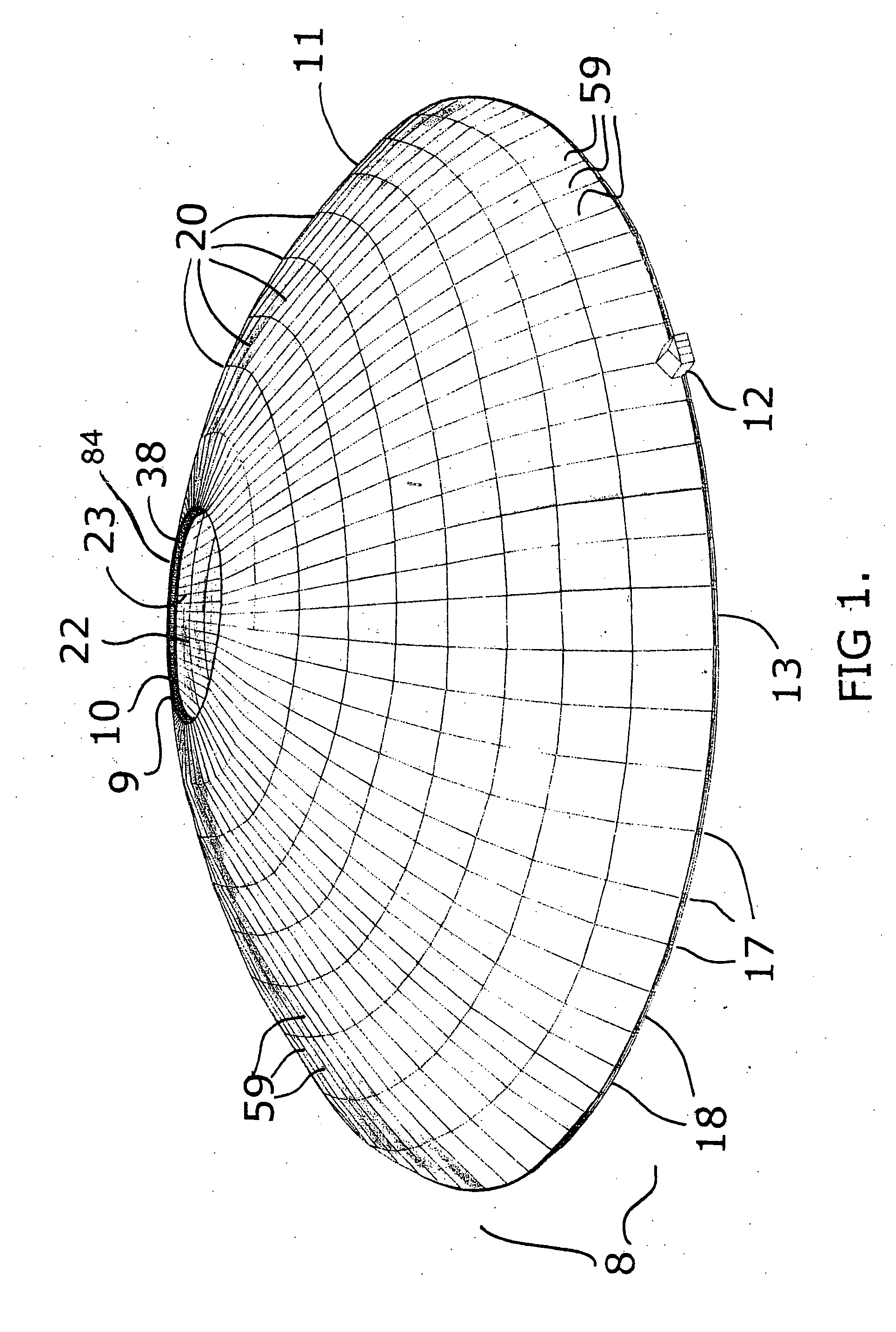

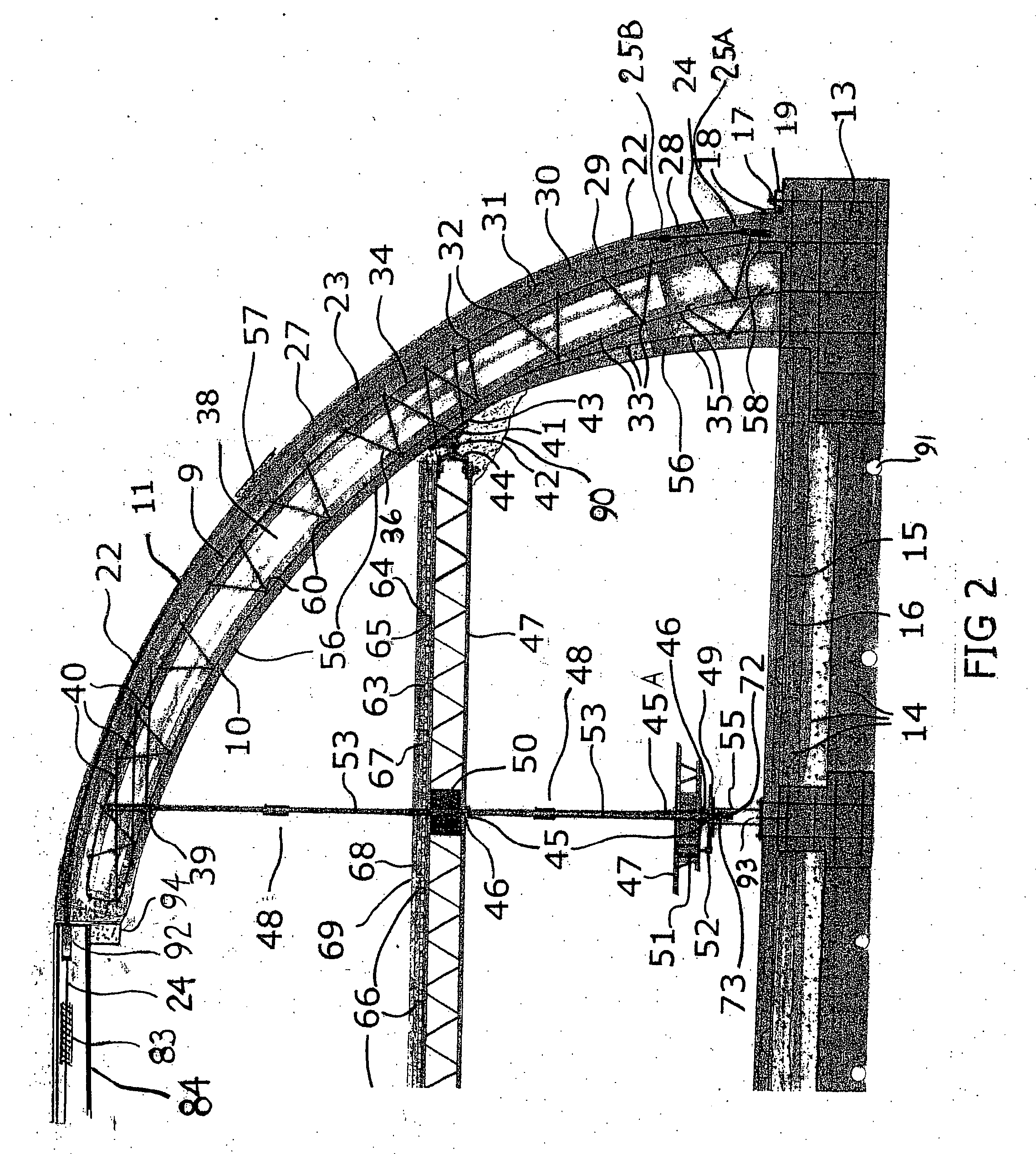

[0051] Referring now to the drawings, and in particular to FIGS. 1 and 2, a Twin Shell, Multiple Shell and / or Trilithic Dome Shell type structure constructed in accordance with one embodiment of the present invention is indicated generally in FIG. 1 and shall be herein after referred to in general as a Multiple Shell Type structure or (MST) structure.

[0052] The MST structure illustrated in FIG. 1, takes the form of a generally semi-spherical shaped dome building having a circular base defined by a footing or foundation 13 (FIGS. 1, 2, 4, 10, 11, 24) that is preferably formed from concrete to establish the desired base diameter and is sized to support the weight of the dome and to withstand various weather and environmental conditions to which such structures may be subjected.

[0053] Briefly the MST structure is constructed by first setting the foundation footing 13 (FIGS. 1, 2, 4, 10, 11, 24) after which a light weight and structurally reinforced air-impervious inflatable air-form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com