Prestressing method for installing large-span double-layer latticed shell structure

A prestressed, long-span technology, applied in the direction of building structure, building materials processing, construction, etc., can solve the problems of reducing construction efficiency and increasing construction costs, so as to reduce construction costs, improve work efficiency and ensure construction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

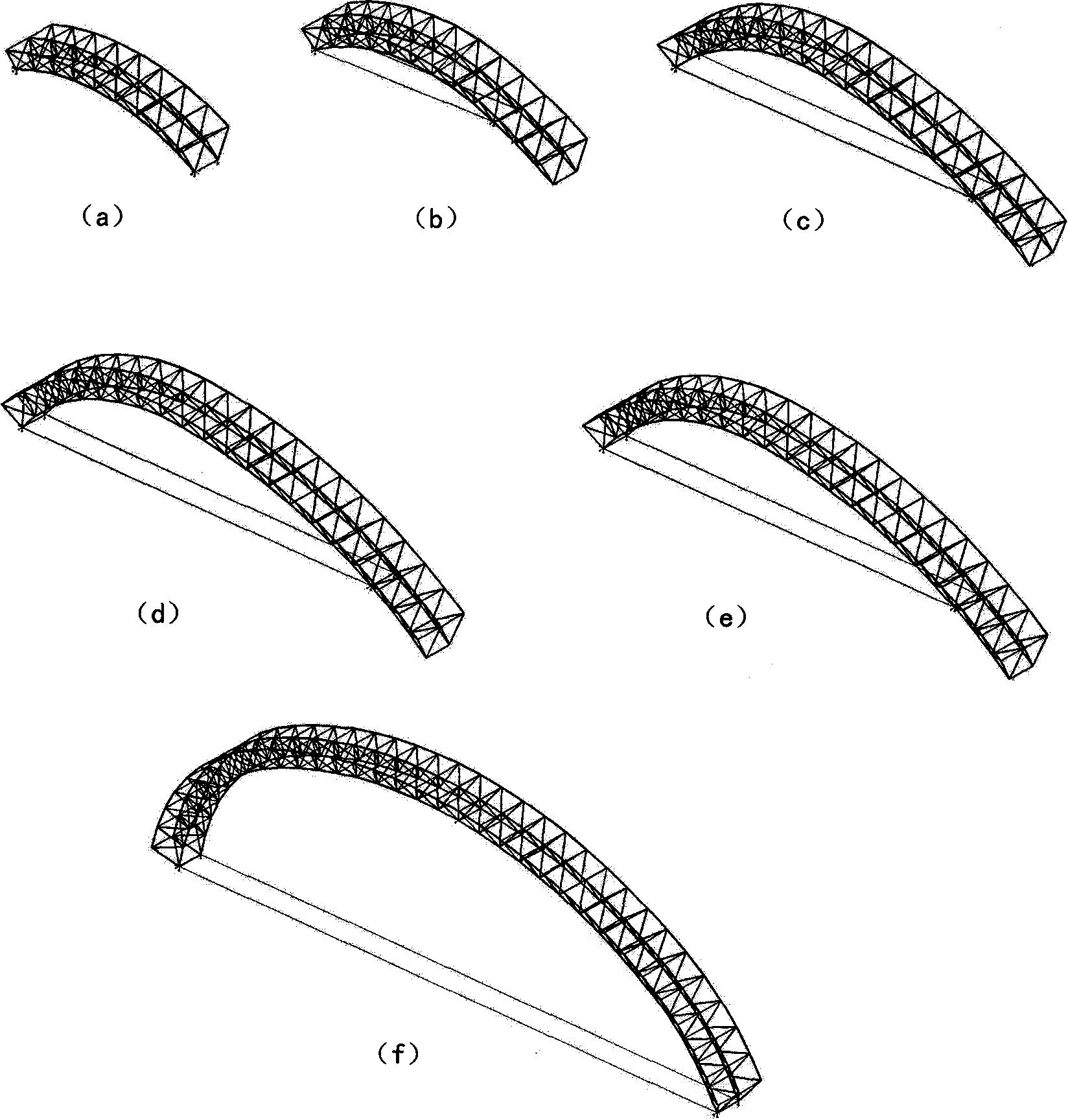

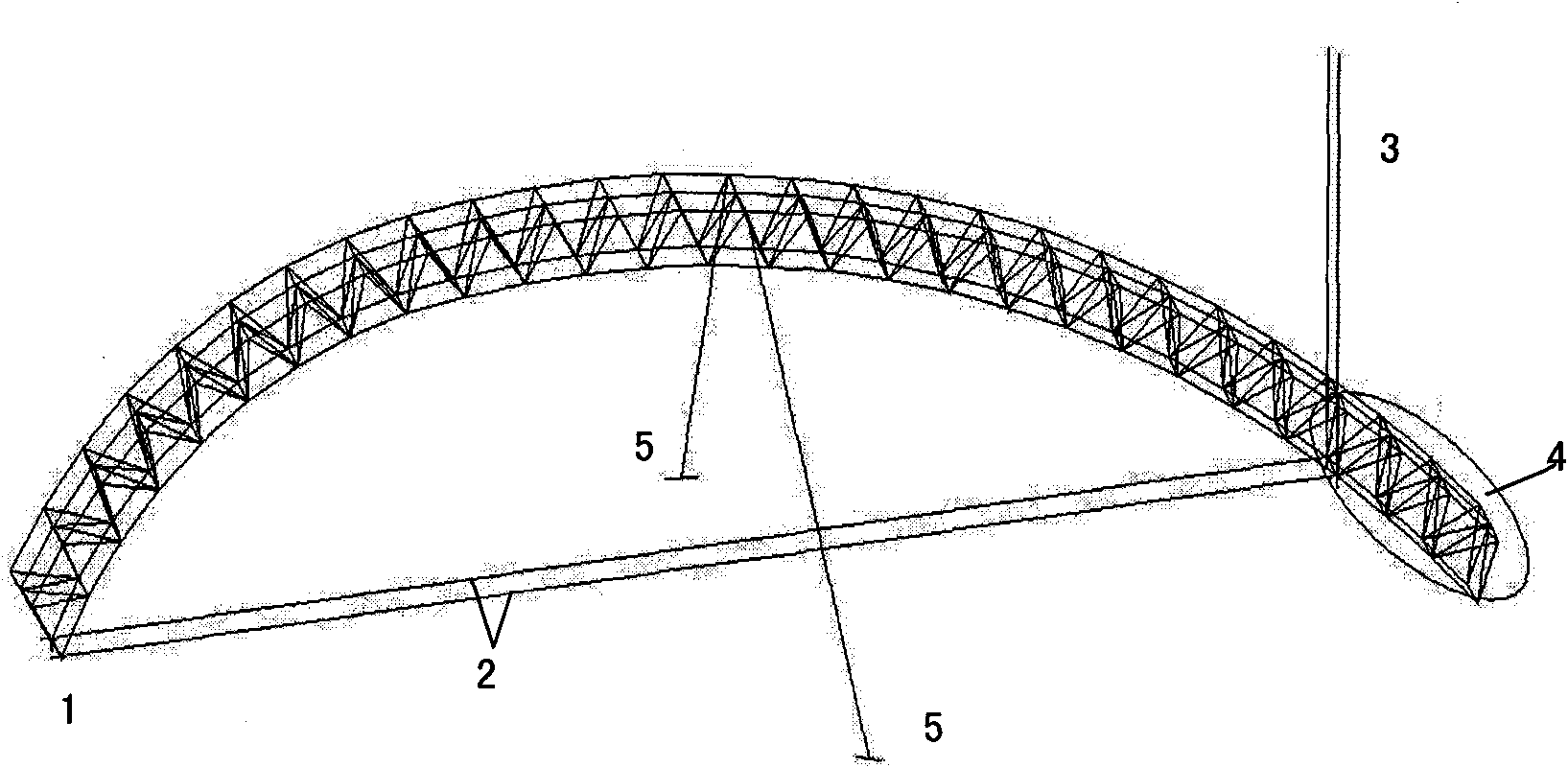

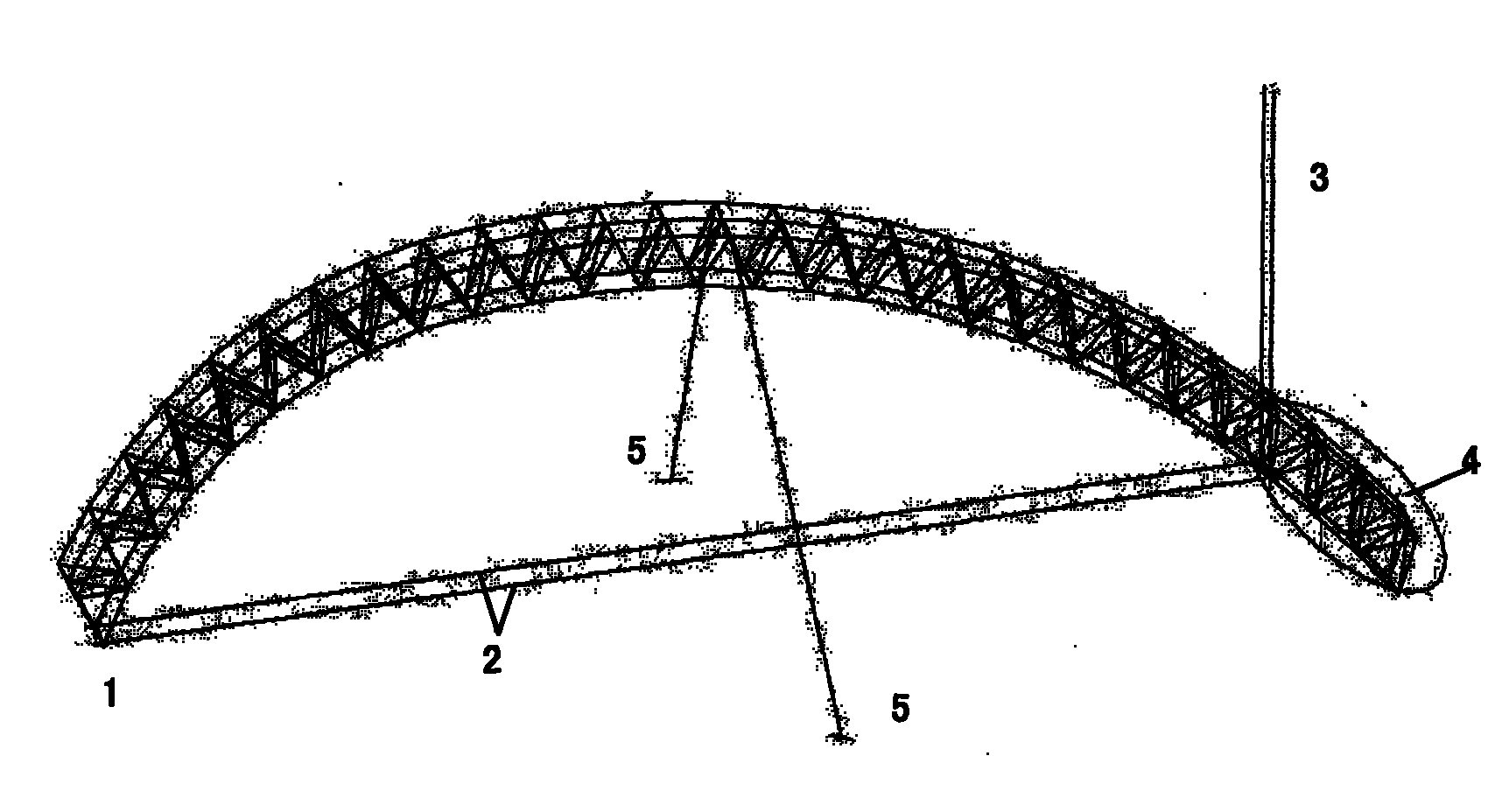

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The installation example is the dry coal shed project of a power plant in Suzhou City, Anhui Province; the total span of the project is 103m, the total depth is 80m, the arching height of the reticulated shell is 37M, and the projected area is about 8240m 2 . The lower chord is point-supported, and the square pyramid bolt ball net frame is placed upright, with a grid size of 4m. The specific installation steps are as follows:

[0015] 1. Reinforce the rotatable support at one end of the reticulated shell so that it can be rotated during the construction process, but it cannot be moved in any direction.

[0016] 2. Press figure 1 In the first step shown in (a), a section of reticulated shell is assembled on the ground, starting from the support at one end to a span of about 30 meters. Due to the short distance, the arching of the reticulated shell is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com