Baffle wind power turbine generating equipment

A technology for wind power generation equipment and power generation equipment, which is applied in the direction of wind power generator components, wind power generation, wind power engines, etc., which can solve problems such as difficulties in manufacturing, installation and maintenance, cost restrictions on tower heights, and restrictions on wind energy utilization, so as to simplify equipment , Increase the power generation capacity of a single machine and improve the efficiency of wind power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

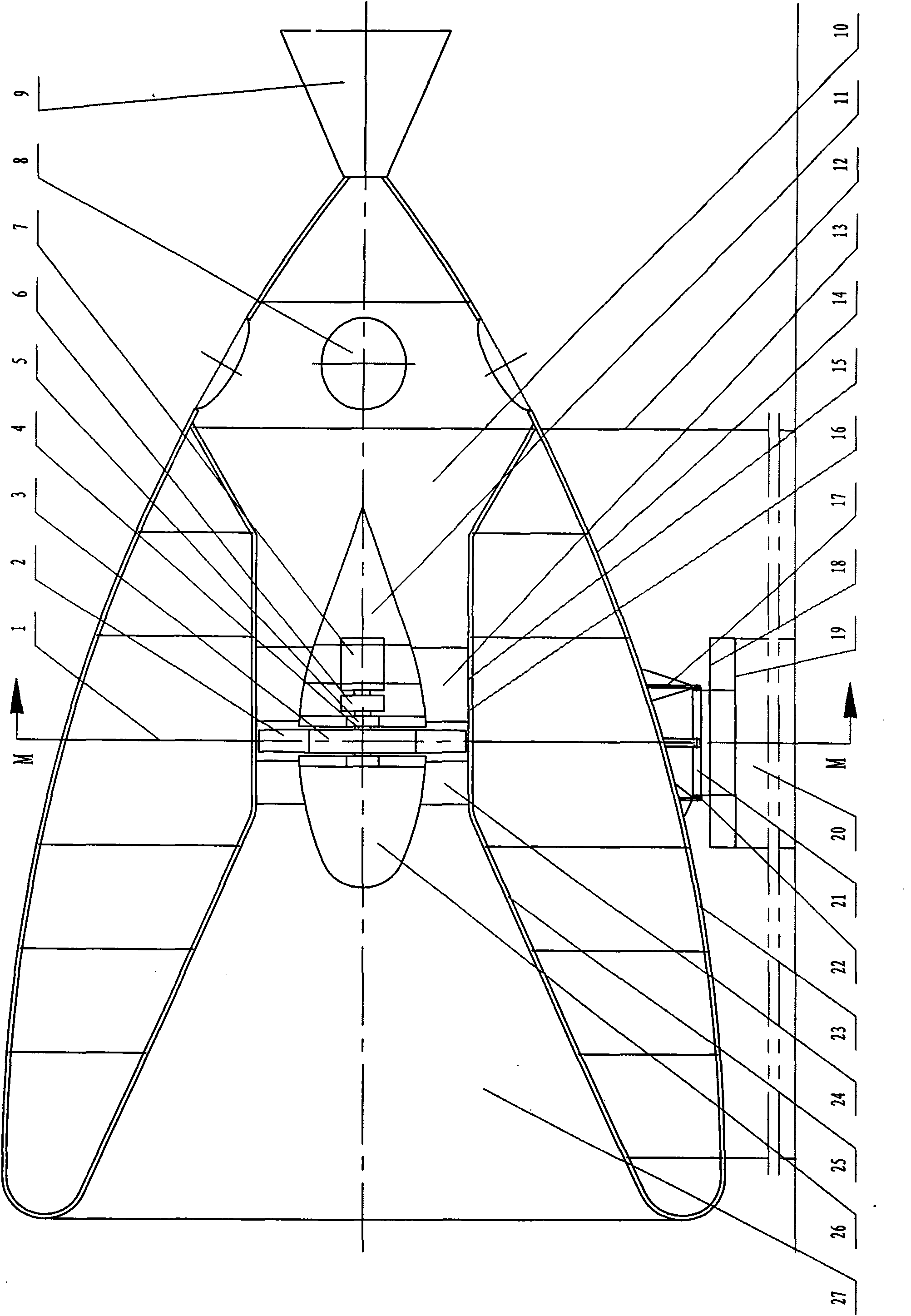

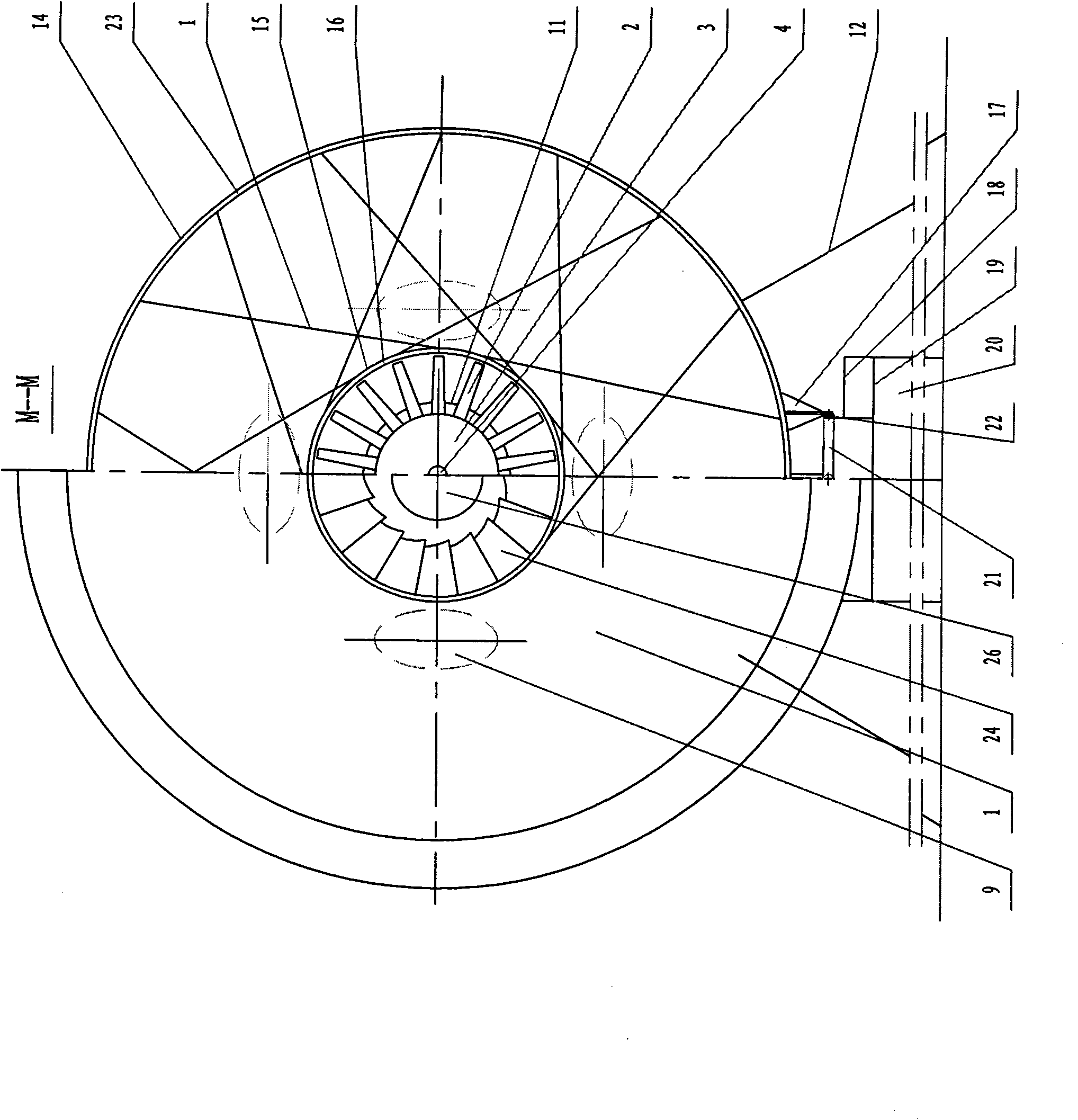

[0052] exist figure 1 , figure 2 Among them, the present invention discloses a deflector wind turbine power generation device, which replaces the bulky propeller wind power generation device.

[0053] The streamlined outer guide body 14 accommodates the main wind power generation equipment to reduce the wind resistance of the overall equipment.

[0054] The spoke suspension structure 1 is used to connect the shell structure of the outer guide body 14 with the thin shell structures such as the shrinkage guide air intake pipe 27, the linear guide pipe 15, and the diffusion guide exhaust pipe 10 to form a light-weight overall structure. The suspension spoke 1 realizes the connection between the above-mentioned shell structures 14 , 27 , 15 , 10 through the ribs 23 , 25 , 16 .

[0055] The turbine power generation equipment is arranged in the center of the outer guide body, inside the linear guide tube 15 .

[0056] The turbine power generation equipment has a contraction guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com