Thin shell structure reinforced type artificial board

A thin-shell structure, enhanced technology, applied in the direction of manufacturing tools, planers, planers, etc., can solve the problems of large glue consumption, high plywood manufacturing cost, hindering popularization and use, etc., to improve the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Using moso bamboo as the raw material, the bamboo green strips of moso bamboo are woven with cotton thread alone to make bamboo curtains with a thickness of 0.8~1.5mm, after drying, use toluene diisocyanate as an adhesive to sizing; fast-growing poplar wood is peeled into 0.7~1.5mm Veneer, impregnated with phenolic resin after drying;

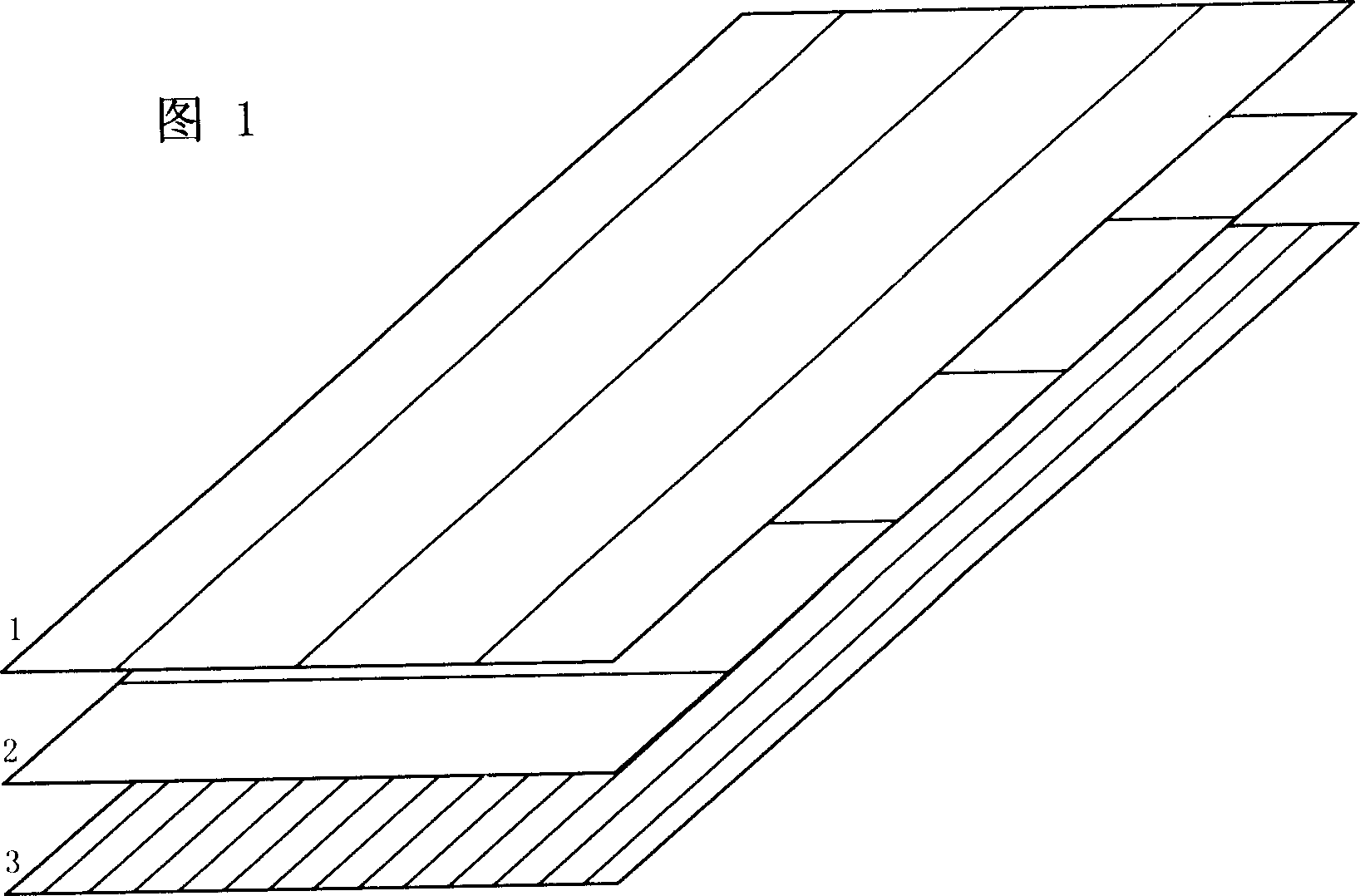

[0025] b. Using the billet structure shown in Figure 1, one layer of bamboo green curtain with isocyanate adhesive and two layers of phenolic resin impregnated poplar veneer under the conditions of temperature of 135~150℃ and pressure of 3.5~4.5MPa Hot-pressed into high-density poplar veneer and bamboo green curtain composite sheet for use;

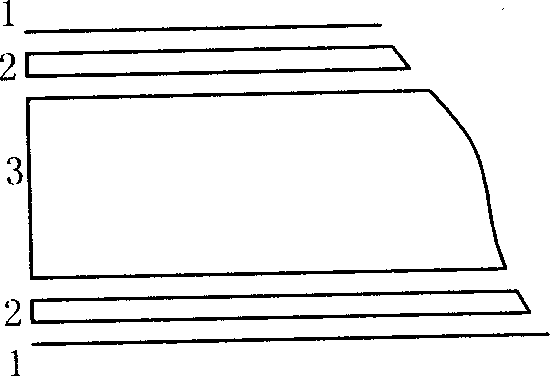

[0026] c. As attached figure 2 As shown, the surface layer (1) adopts birch decorative veneer impregnated with phenolic resin and plasticized at high temperature and high pressure, layer (2) is high-density poplar veneer and bamboo green curtain composite sheet, and the core layer (3) adopts 9 layers...

Embodiment 2

[0028] As attached figure 2 As shown, the surface layer (1) is made of melamine impregnated decorative paper, the layer (2) is a high-density poplar veneer and bamboo green curtain composite sheet, and the core layer (3) is made of 15mm-thick particle board, after sizing with ordinary phenolic resin adhesive The composite blank is hot-pressed into a thin-shell structure reinforced wood-based panel at a temperature of 135-145°C and a pressure of 0.8-1.2MPa.

[0029] The rest is the same as in Example 1.

[0030] Using the method and structure provided by the present invention, the main physical and mechanical properties of the thin-shell structure reinforced wood-based panel are as follows:

[0031] Density——0.6~0.75g / cm 3

[0032] Elastic modulus-6000~15000MPa

[0033] Static bending strength——50~120MPa

[0034] Impact toughness——60~100J / m 2

[0035] The purpose of the invention of effectively using bamboo green strip resources and reducing manufacturing costs is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com