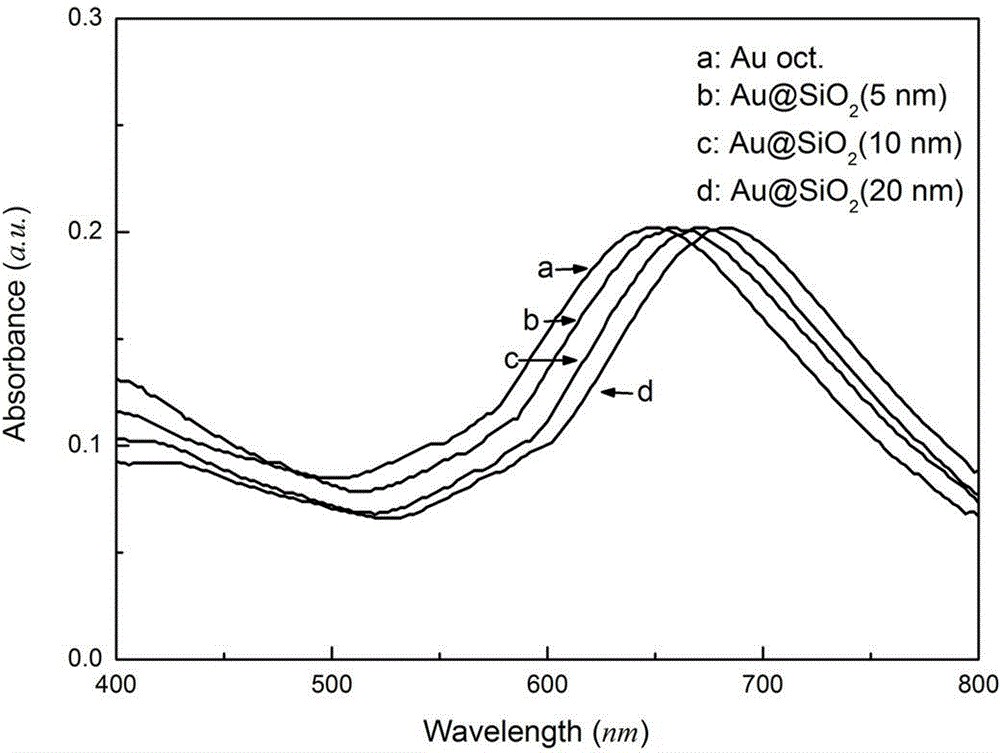

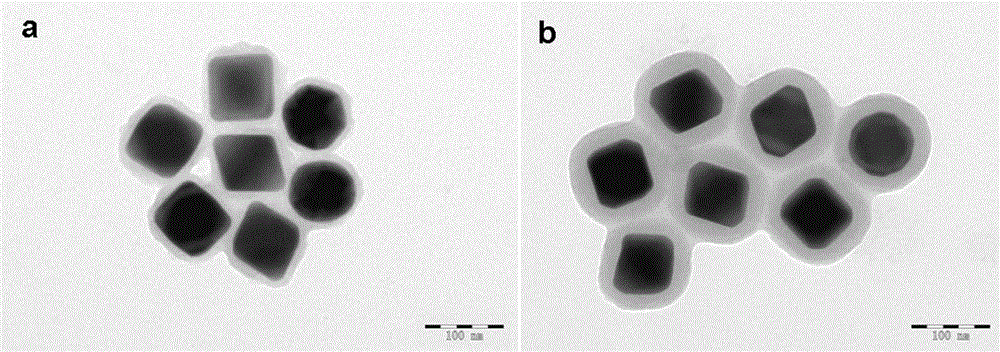

Controllable preparation method for Au@SiO2 nano-composite material with ultra-thin shell

A nanocomposite material, ultra-thin technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of limited surface interaction, unfavorable reactant penetration, great influence on the performance of core-shell materials, etc., to achieve regular shape and good spectrum Performance, Ease of Ultrasonic Dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All reagents used were conventional medicines purchased from reagent companies. Preparation of aqueous solution: 18 megohm deionized water: polydimethyldiallyl ammonium chloride PDDA, (400,000) made into 1.25 mol / L aqueous solution, chloroauric acid (HAuCl 4 ) into a 1.0 mol / L aqueous solution, and L-arginine into a 0.02 mol / L aqueous solution.

[0025] The experimental content of the present invention will be further described in detail below in conjunction with specific implementation examples.

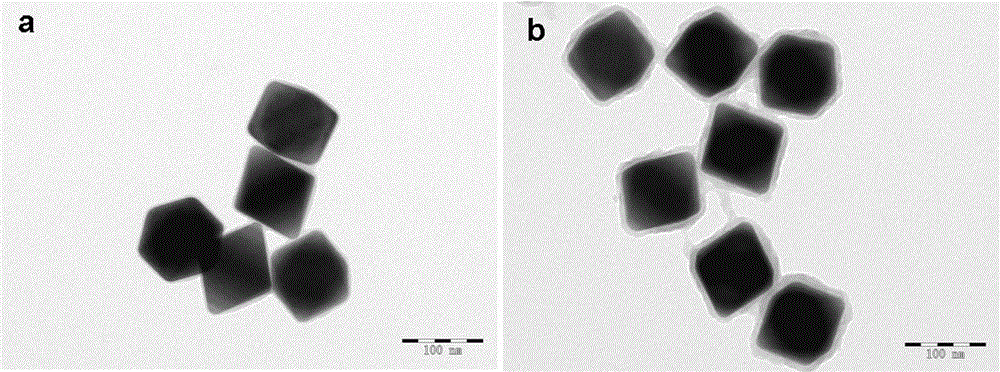

[0026] 1. Preparation of Gold Octahedral Nanoparticles

[0027] Add 1 mol / L HAuCl to the glass vial 4 Solution 35 μL, then pour 70 mL ethylene glycol, and then add 1.40 mL polydimethyldiallylammonium chloride (PDDA) (400,000, 1.25 mol / L), the final concentration of each component in the system: HAuCl 4 : 0.50 mmol / L, PDDA: 25 mmol / L. After the above solution was fully mixed, it was placed in an oil bath at 220°C for two hours, and finally cooled to room temperature. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com