Patents

Literature

54 results about "Snap through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

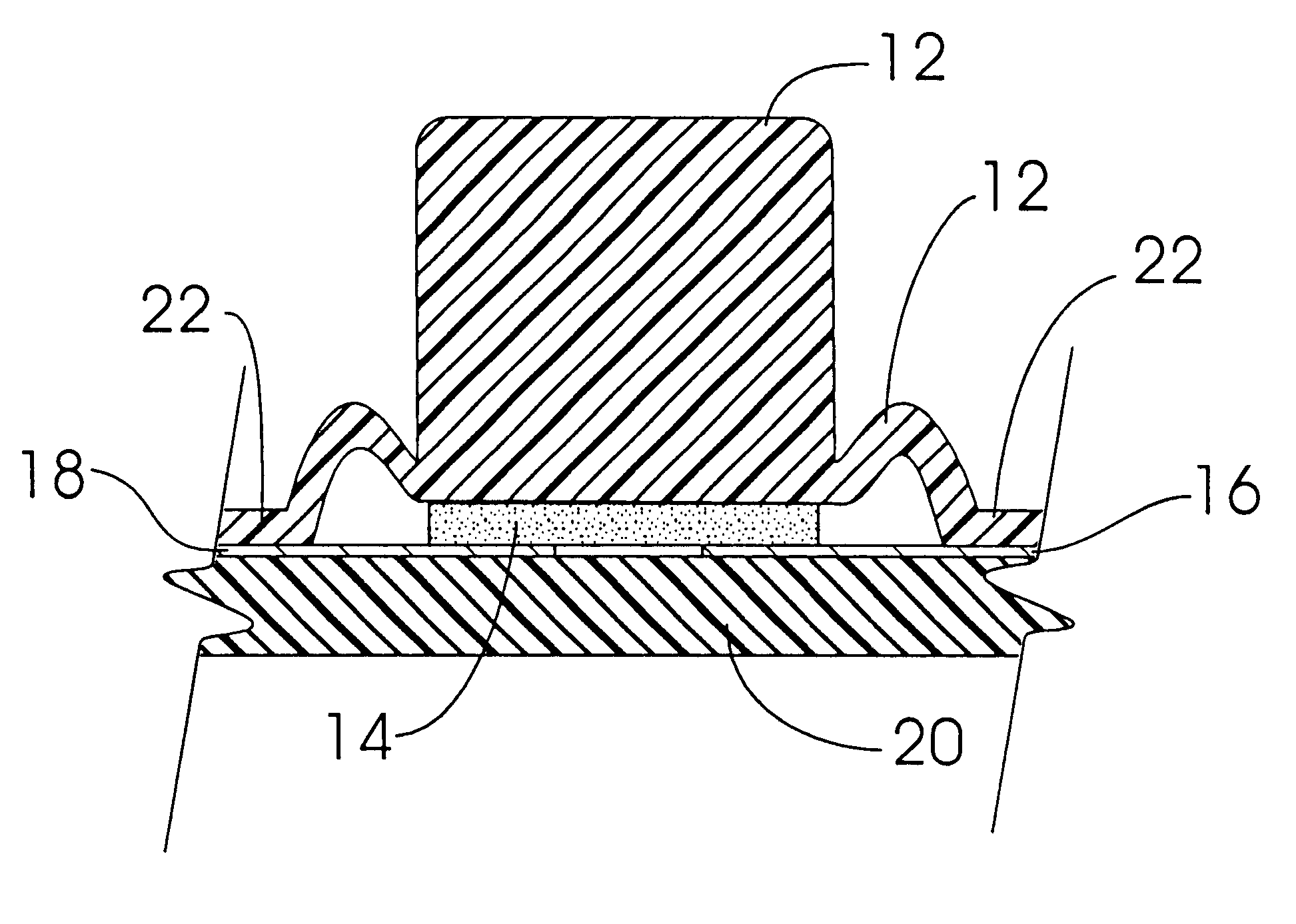

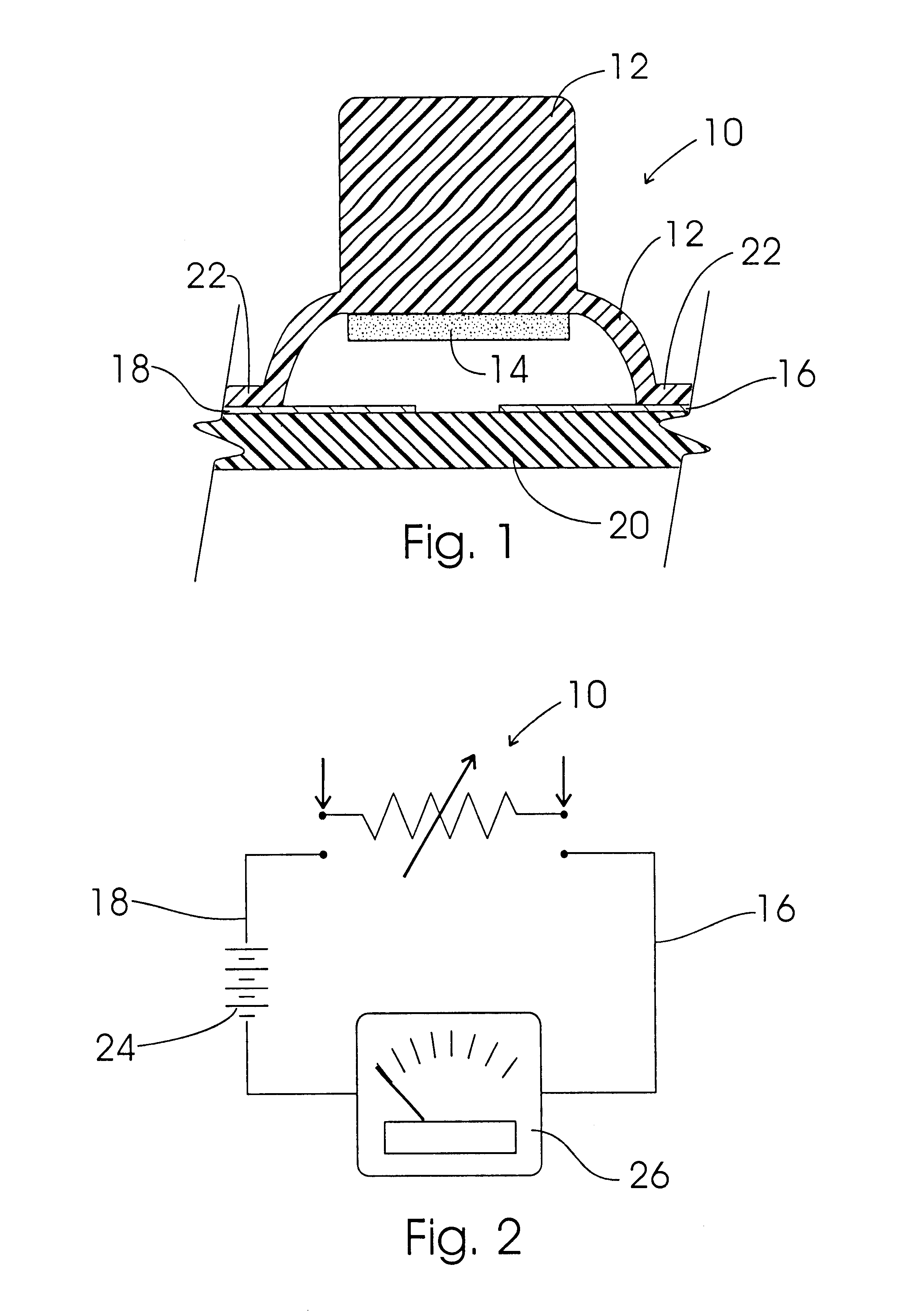

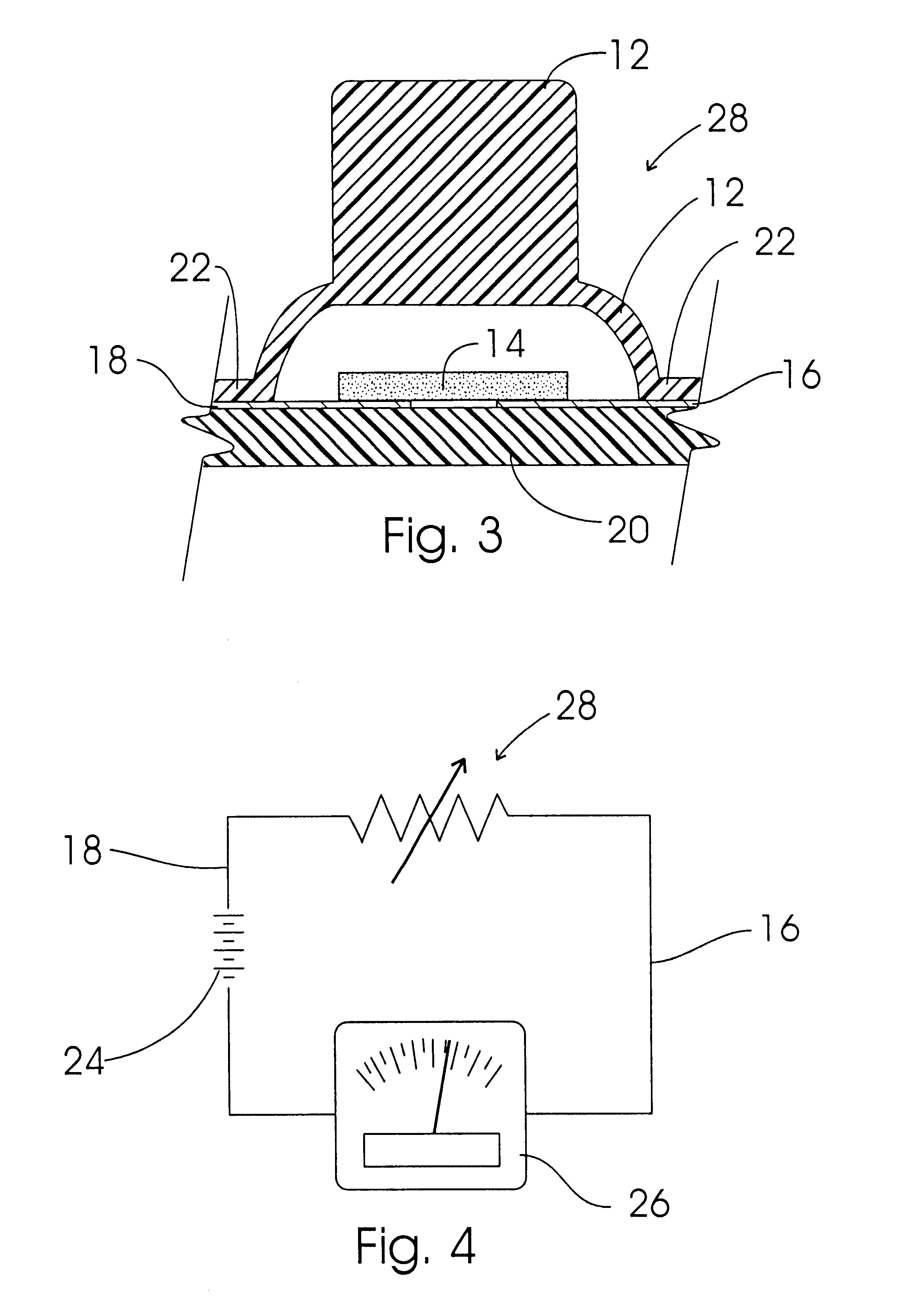

Variable sensor with tactile feedback

InactiveUS6344791B1Input/output for user-computer interactionManual control with multiple controlled membersTouch PerceptionEngineering

Owner:ANASCAPE

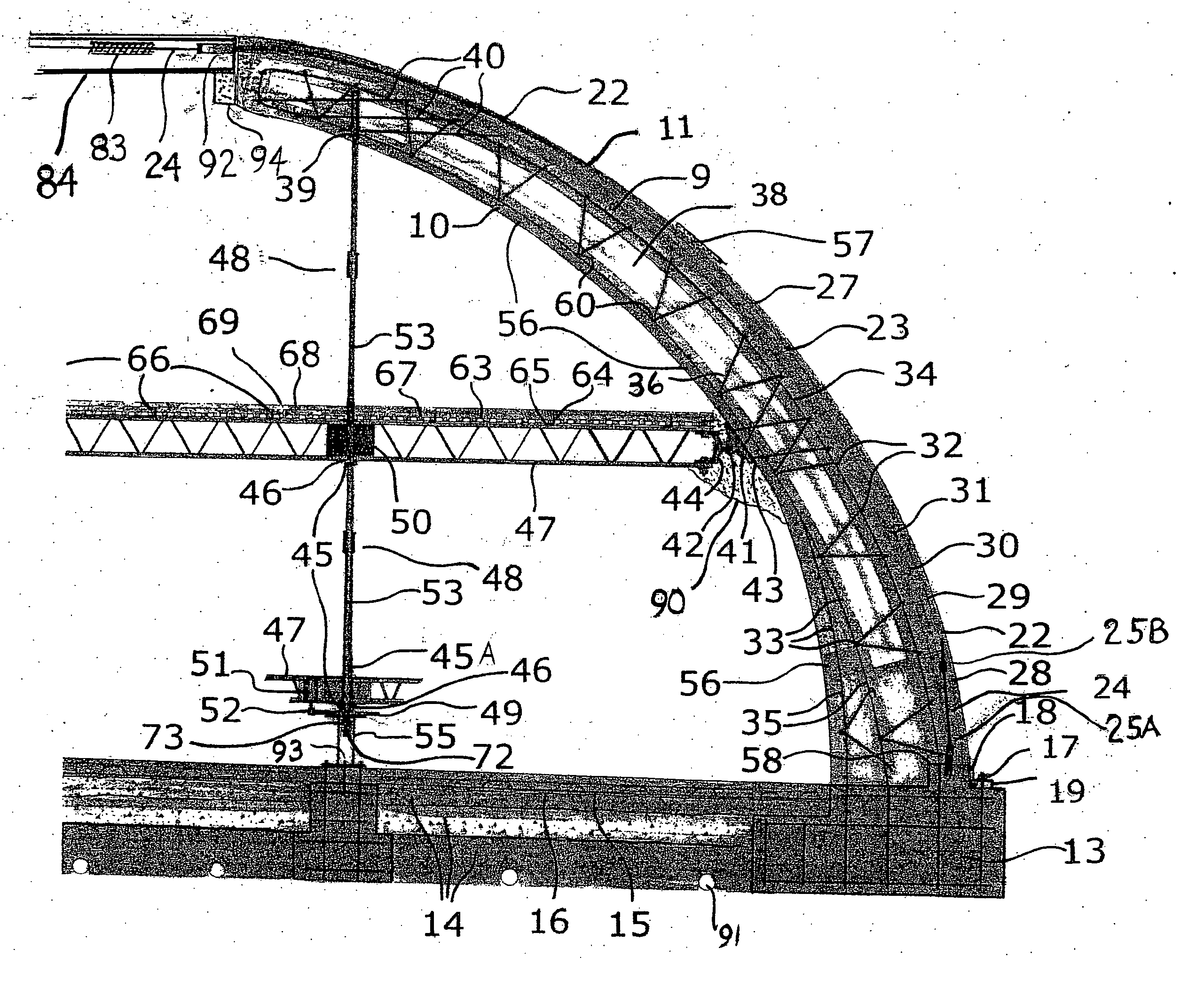

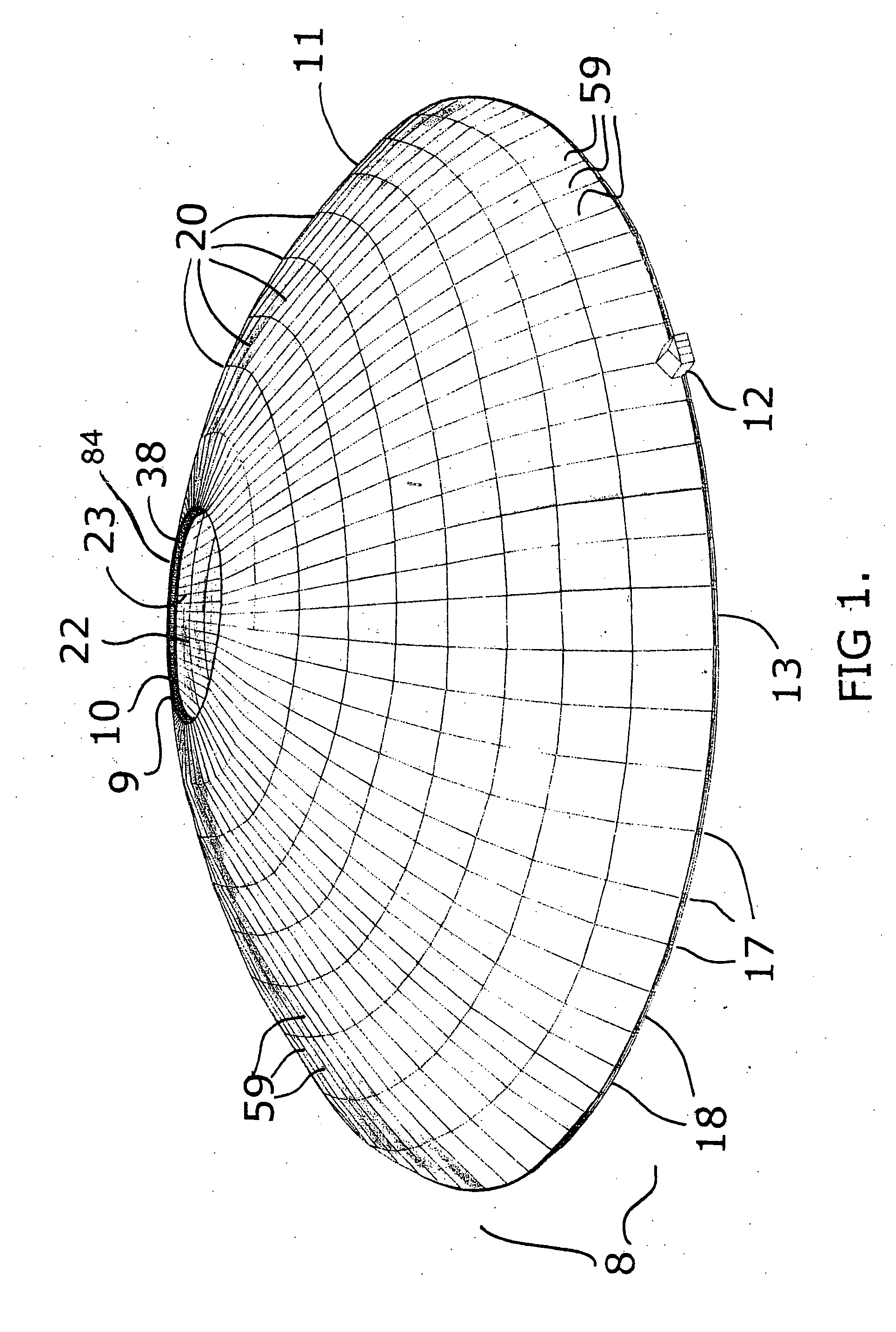

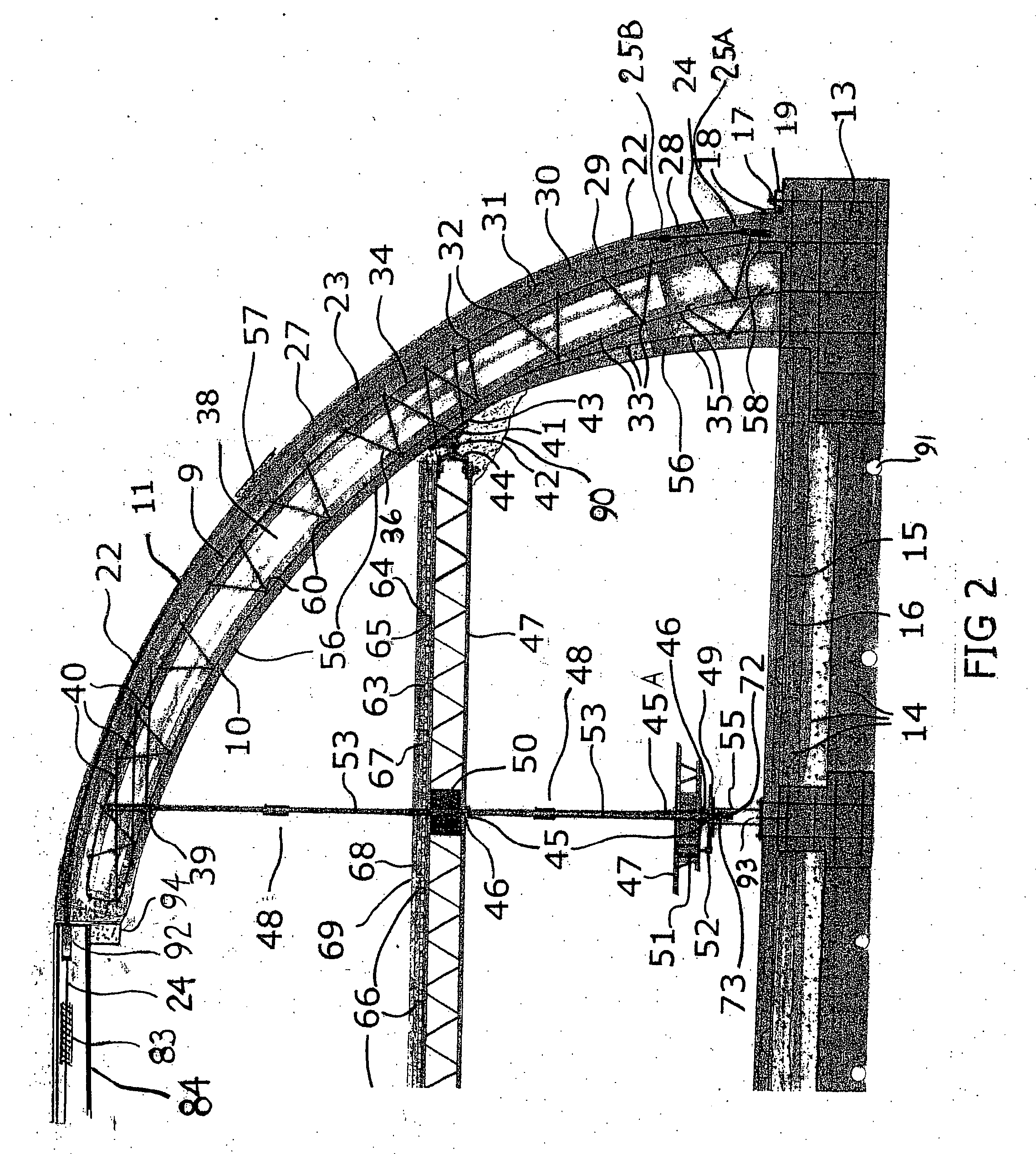

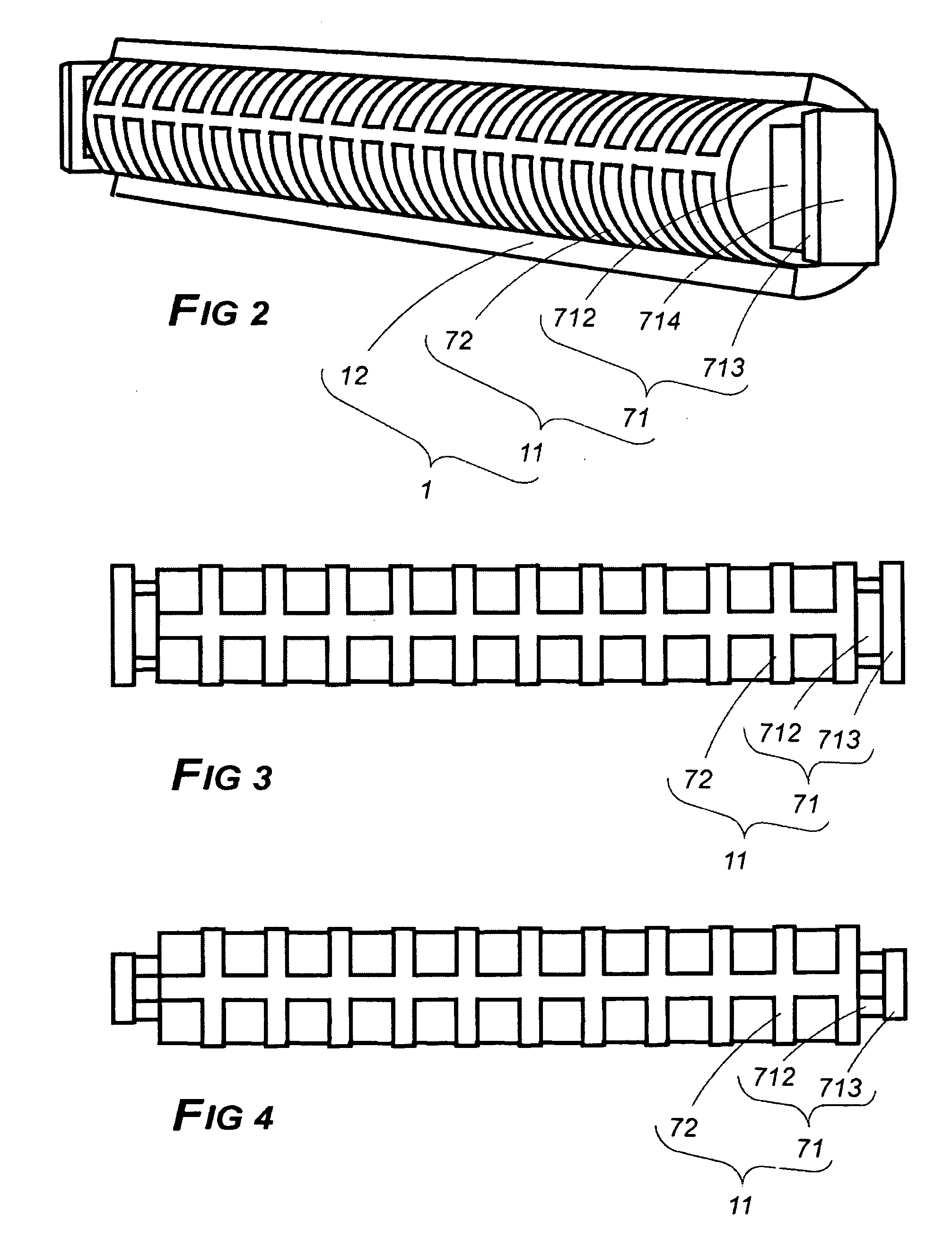

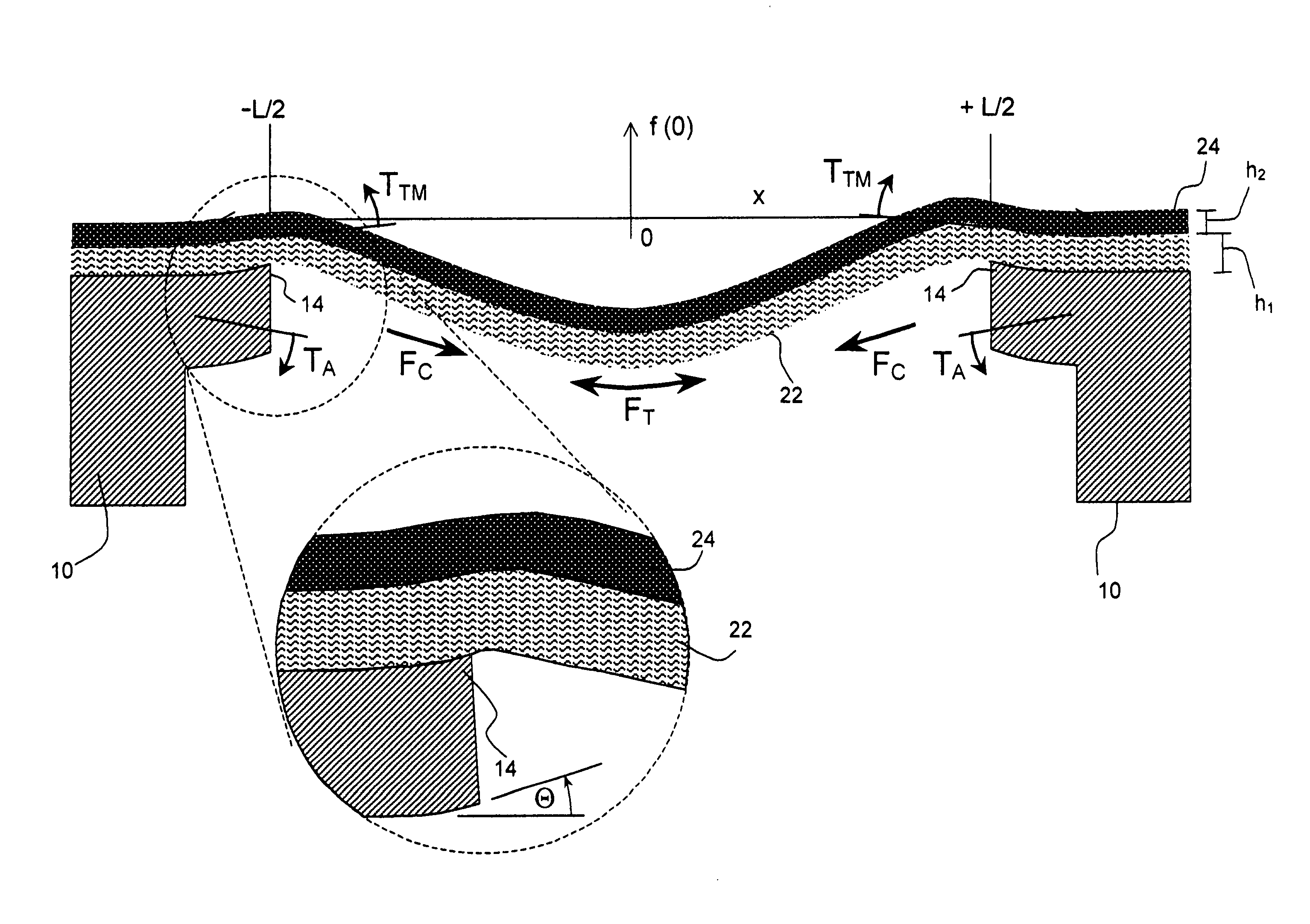

Trilithic and/or twin shell dome type structures and method of making same

InactiveUS20050210767A1Quick connectionImprove load-bearing strengthBuilding roofsArched structuresShotcreteThin shells

Trilithic Shell, Twin Shell, Multiple Shell, Curvilinear Shell as well as Free-formed Structures described herein each employ an inflatable membrane having a peripheral edge secured to an outer foundation base. An ultra-light membrane (air-form) having a network of internal cross connecting restraints is additionally secured to the inner foundation base to permit a novel and unique curvilinear surface. Pressurization then creates the backdrop upon which various urethane layers are applied which when laced with rigidifying tubes become the defining backdrop beneath which numerous cross connecting braces which when snapped into position effectively lock an inner framework to an outer framework thereby producing a self supporting truss like structure both compatible with either current dome construction and / or conventional construction practices. Shotcrete being then sprayed from the interior over said urethane coated backdrop forms highs at framework intersections and natural lows in between followed by the insertion of inflated cell tubes which span the created network of horizontal and vertical cavities are next over sprayed with urethane foam necessary to form the next natural backdrop over which two or more shotcrete / steel reinforced separate yet cross connected planes may be achieved. Such multiple yet independent rigid layers now having thousands of inner-connecting cross braces through which interior voids become natural chase-ways effectively displace 50% or more of what might otherwise be solid concrete as would be the case with all prior art thin shell structures and / or conventional stem wall construction practices. Such Free Formed curve-linear structures effectively reduce material and labor costs by as much as 50%, eliminate snap-through or oil-can buckling tendencies, enhance overall structural capacity, eliminate all height to diameter restraints, permit larger structures, facilitate floor suspension and attachment, and allow mechanical, electrical and HVAC distribution through interior chase-ways which cannot be achieved with prior art concrete thin shell single thickness structures and / or conventional stem wall, construction practices to date.

Owner:DEFEVER MICHAEL D +1

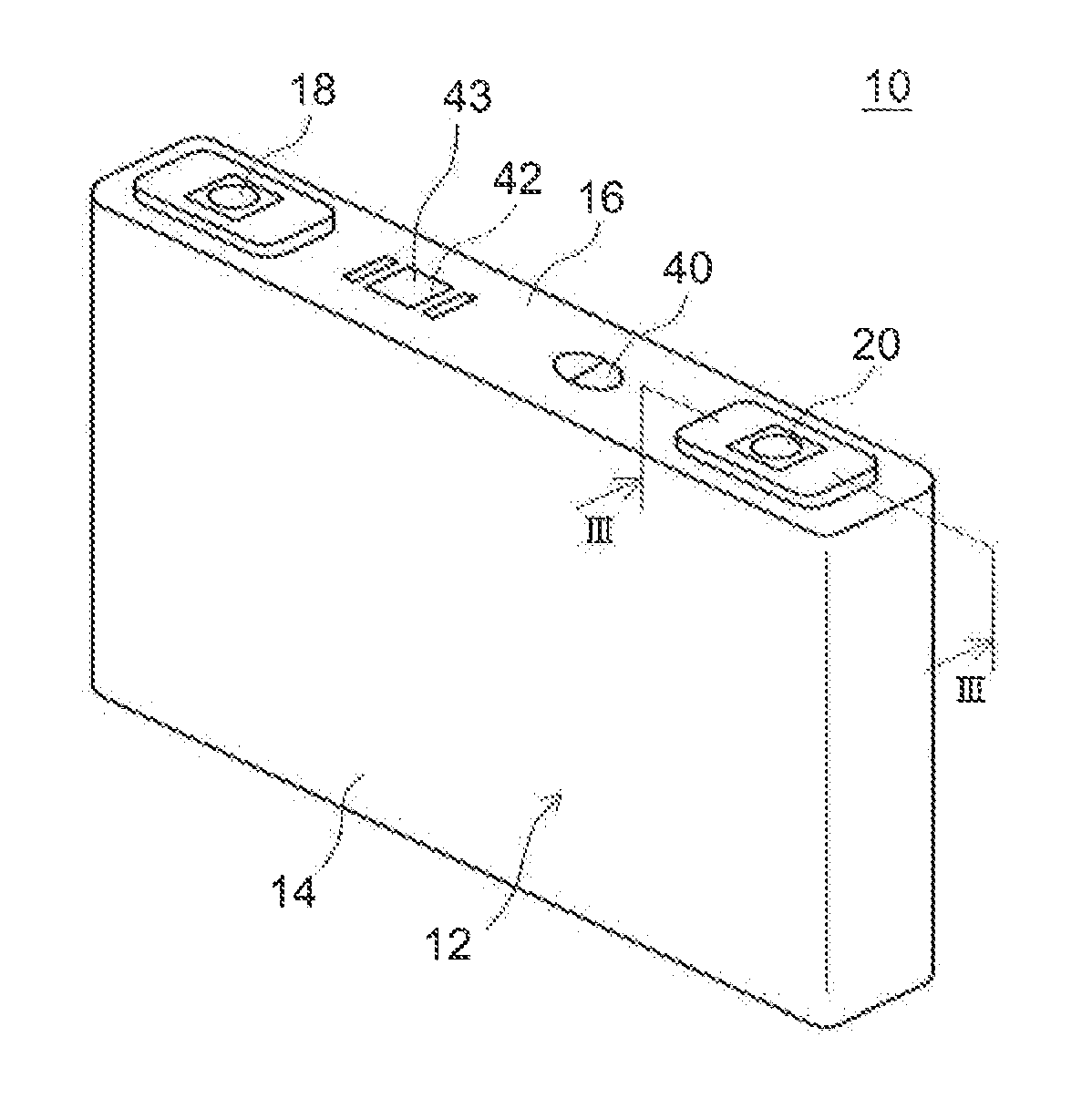

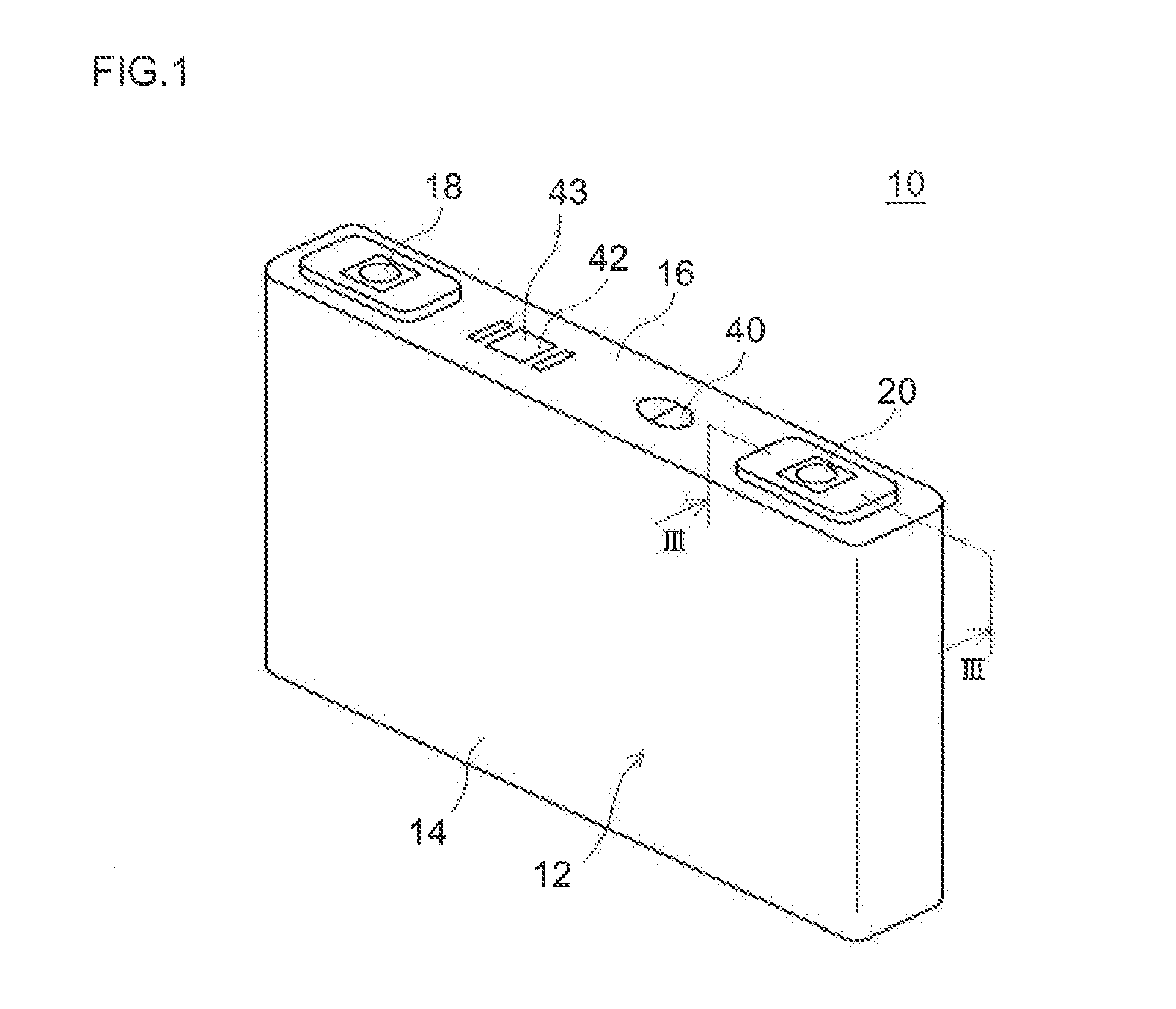

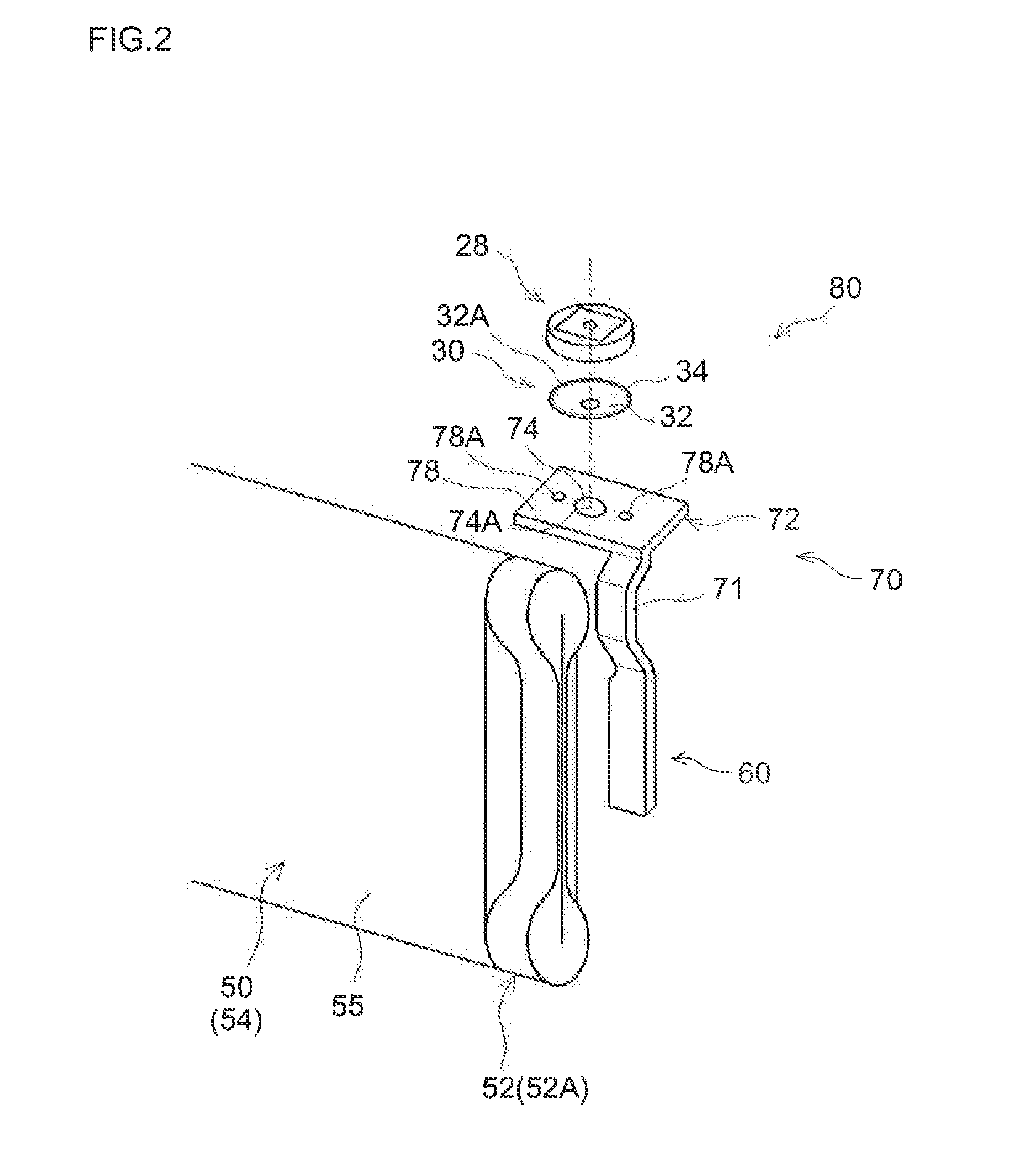

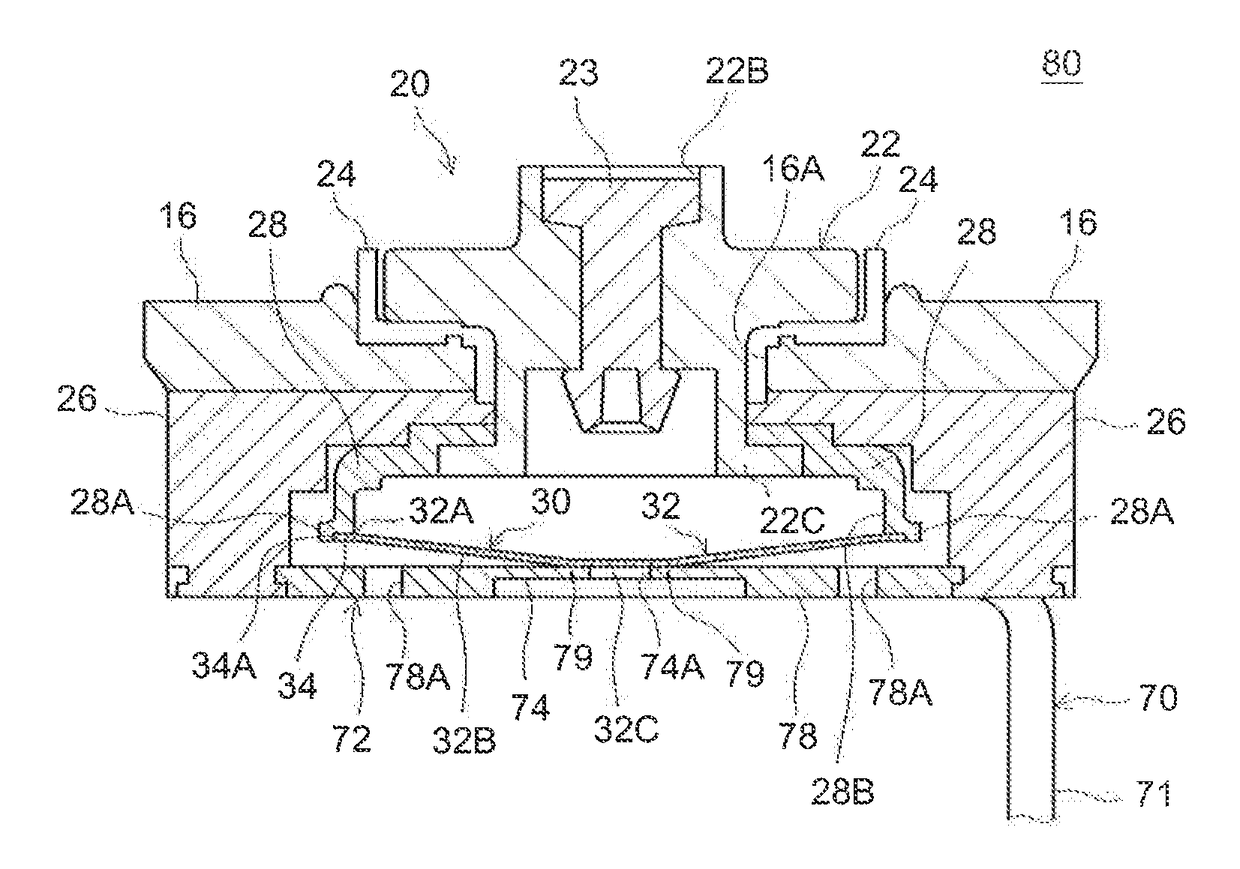

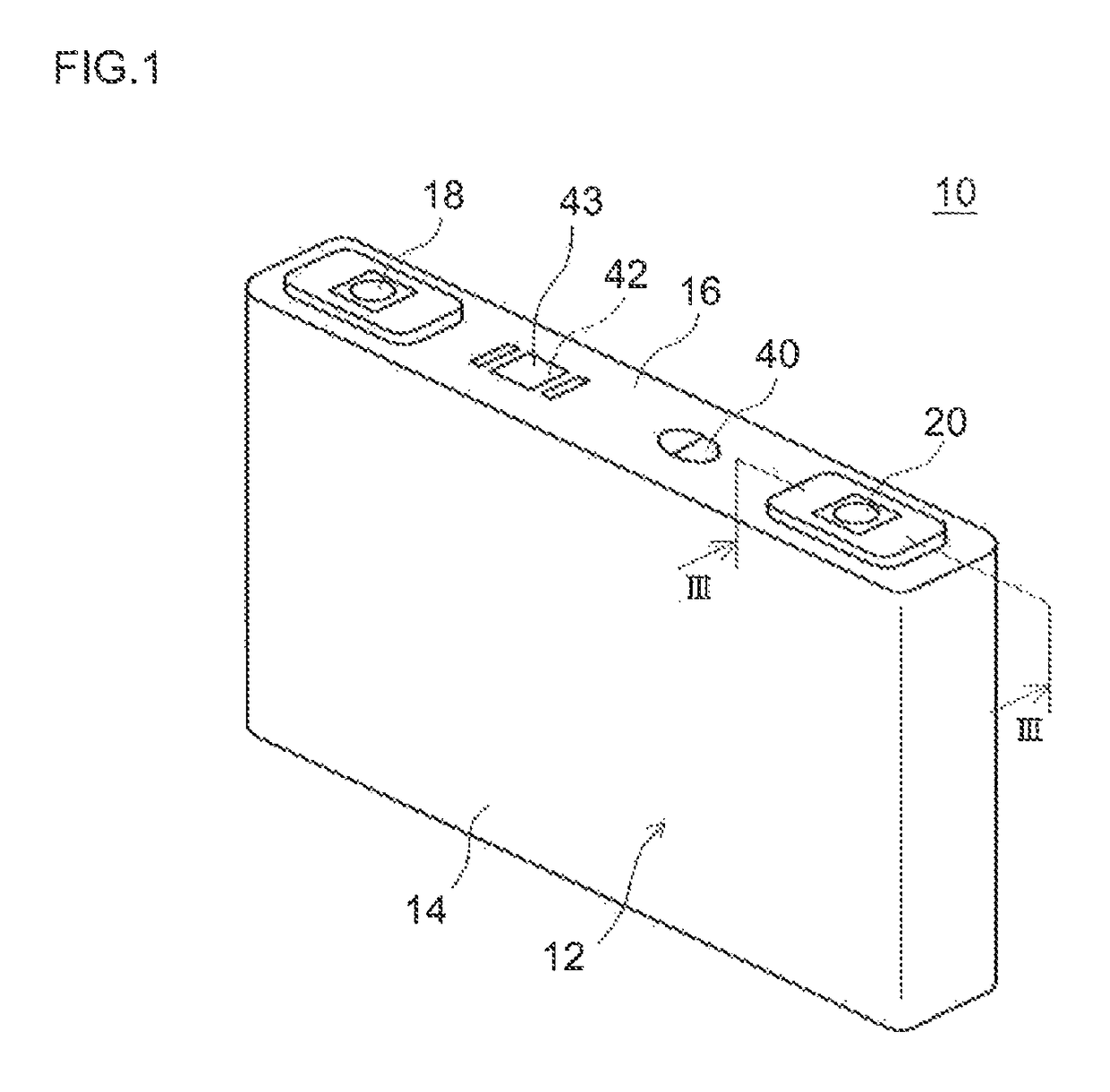

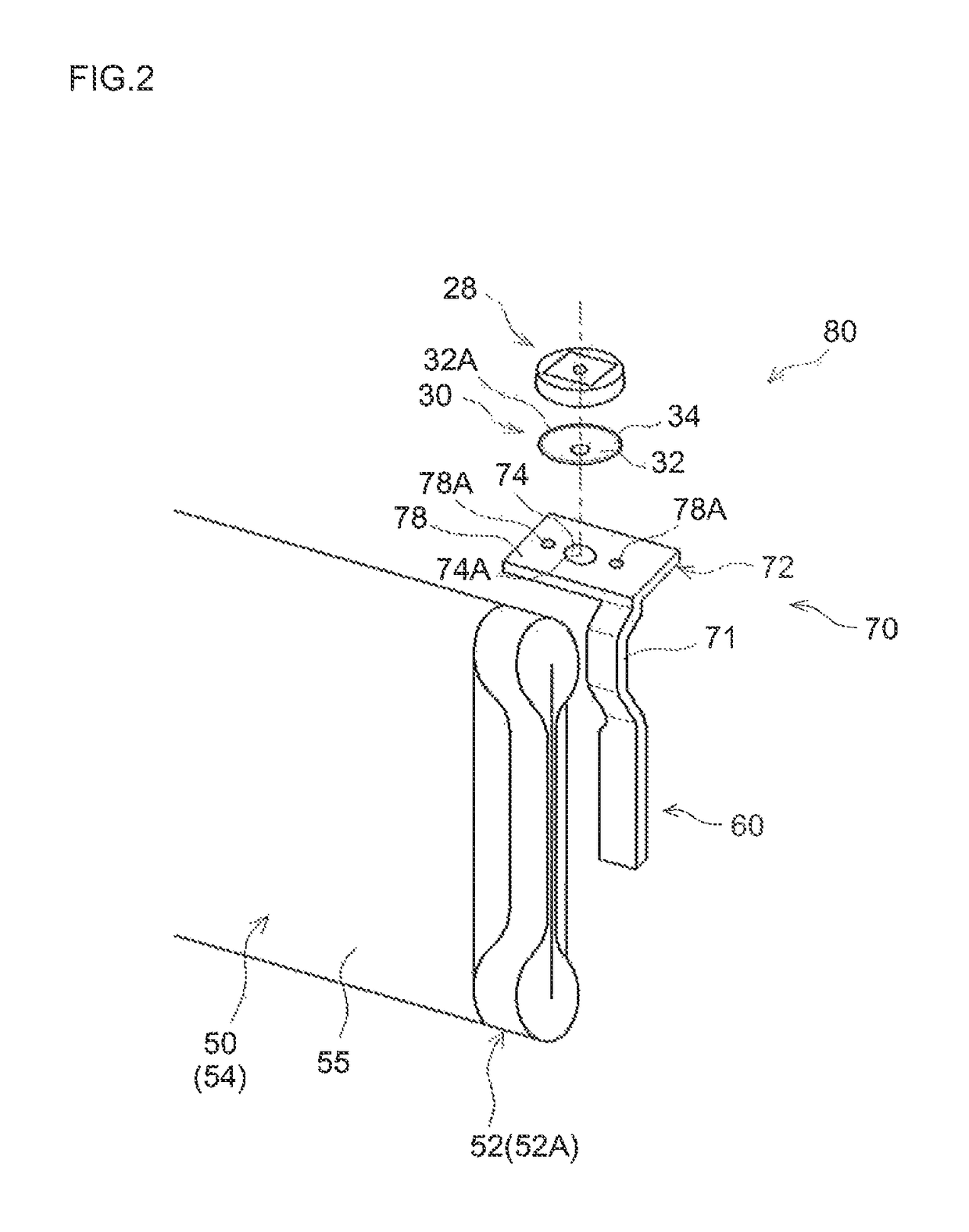

Sealed secondary battery

ActiveUS20150171411A1Rapid disconnectionSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPressure riseEngineering

There is provided a sealed secondary battery whose current-blocking system yields little change in the actuation pressure even on long-term use. The sealed secondary battery comprises a current-blocking system 80 that is actuated by a pressure rise inside a battery case 12 to disconnect conduction path between an electrode and an electrode terminal. Current-blocking system 80 comprises a pressure-sensitive member having a pressure-sensitive deformable portion 32 that deforms from a first state via snap-through deformation to a second state upon a pressure rise inside battery case 12, and is configured to disconnect the conduction path by snap-through deformation of pressure-sensitive deformable portion 30.

Owner:TOYOTA JIDOSHA KK

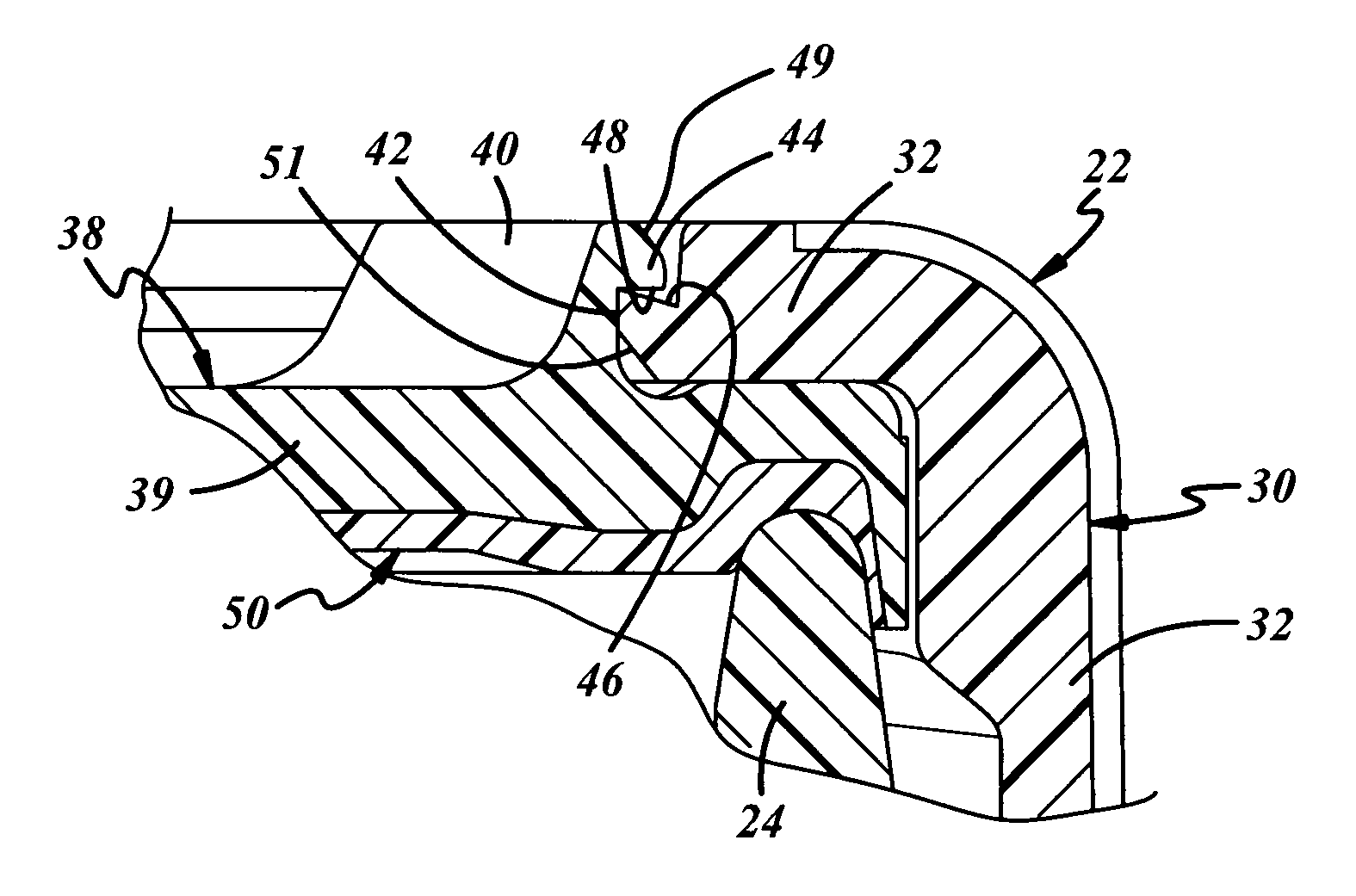

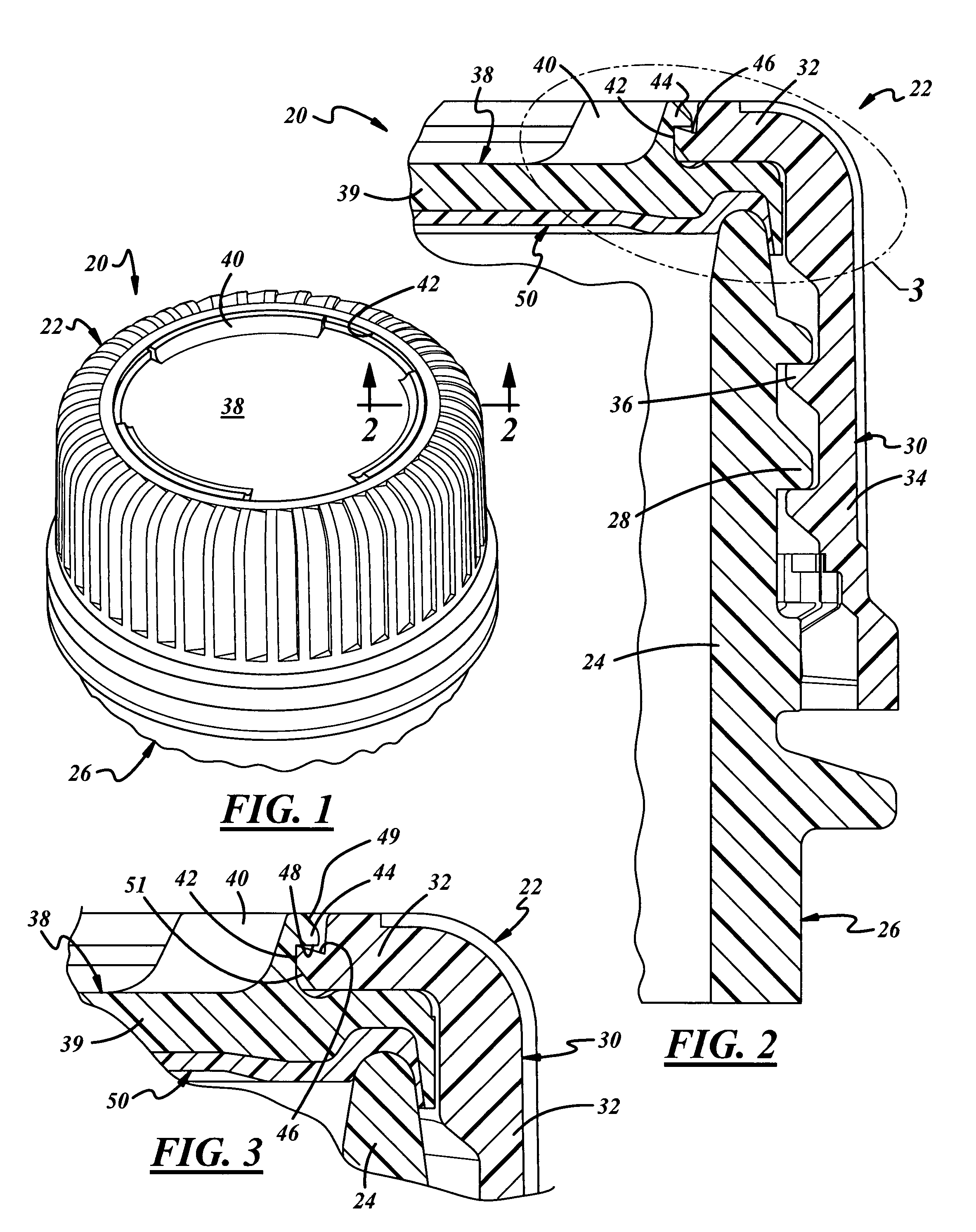

Closure and package for high-temperature applications

A plastic closure includes a plastic closure shell having a base wall with a central opening and a skirt for securing the closure to a container neck finish. A plastic disk includes angularly spaced fingers extending into the central opening of the shell base wall and external beads on the fingers for engaging an inner periphery of the central opening to retain the disk within the shell. The beads have flat undersurfaces and the inner periphery of the central opening has a ledge with a conical surface engaged by the beads. Any doming that occurs in the disk and / or the closure shell base wall increases the surface contact between the finger beads and the opposing surface of the ledge so that removal of the shell from a container neck finish will simultaneously lift and remove the disk from the neck finish without having the beads snap through the central opening in the shell so that the shell is removed while the disk is retained on the neck finish.

Owner:BERRY PLASTICS CORP

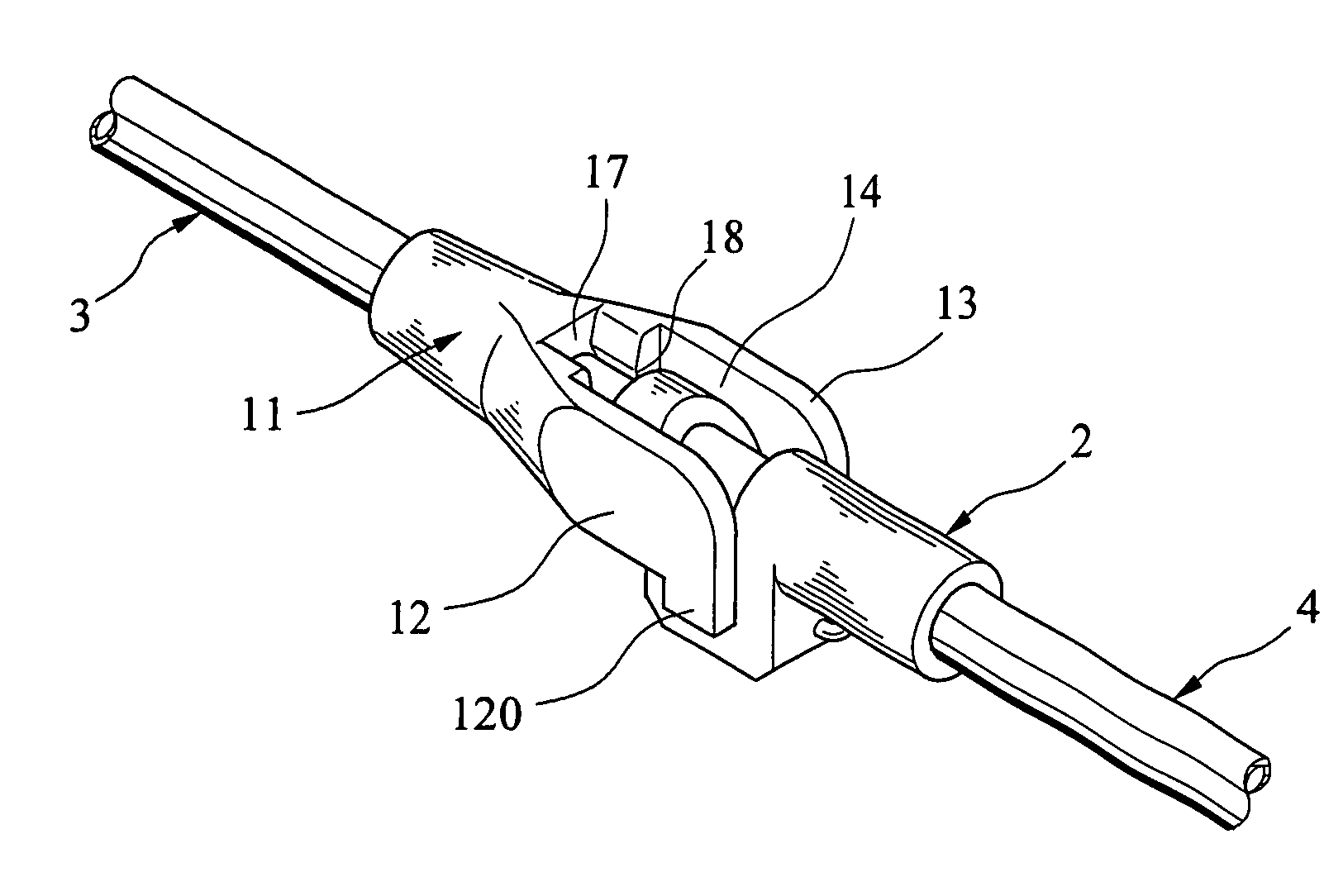

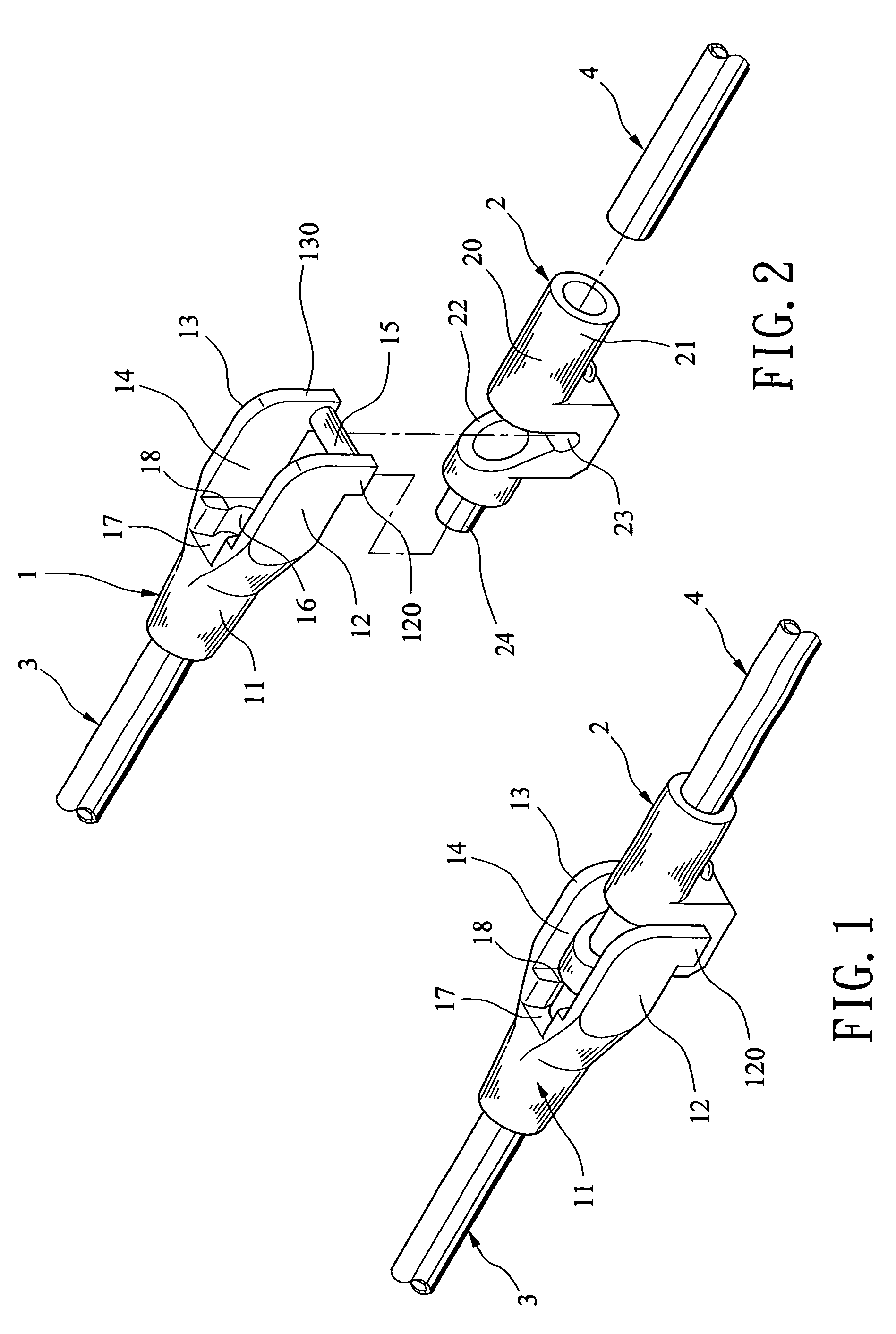

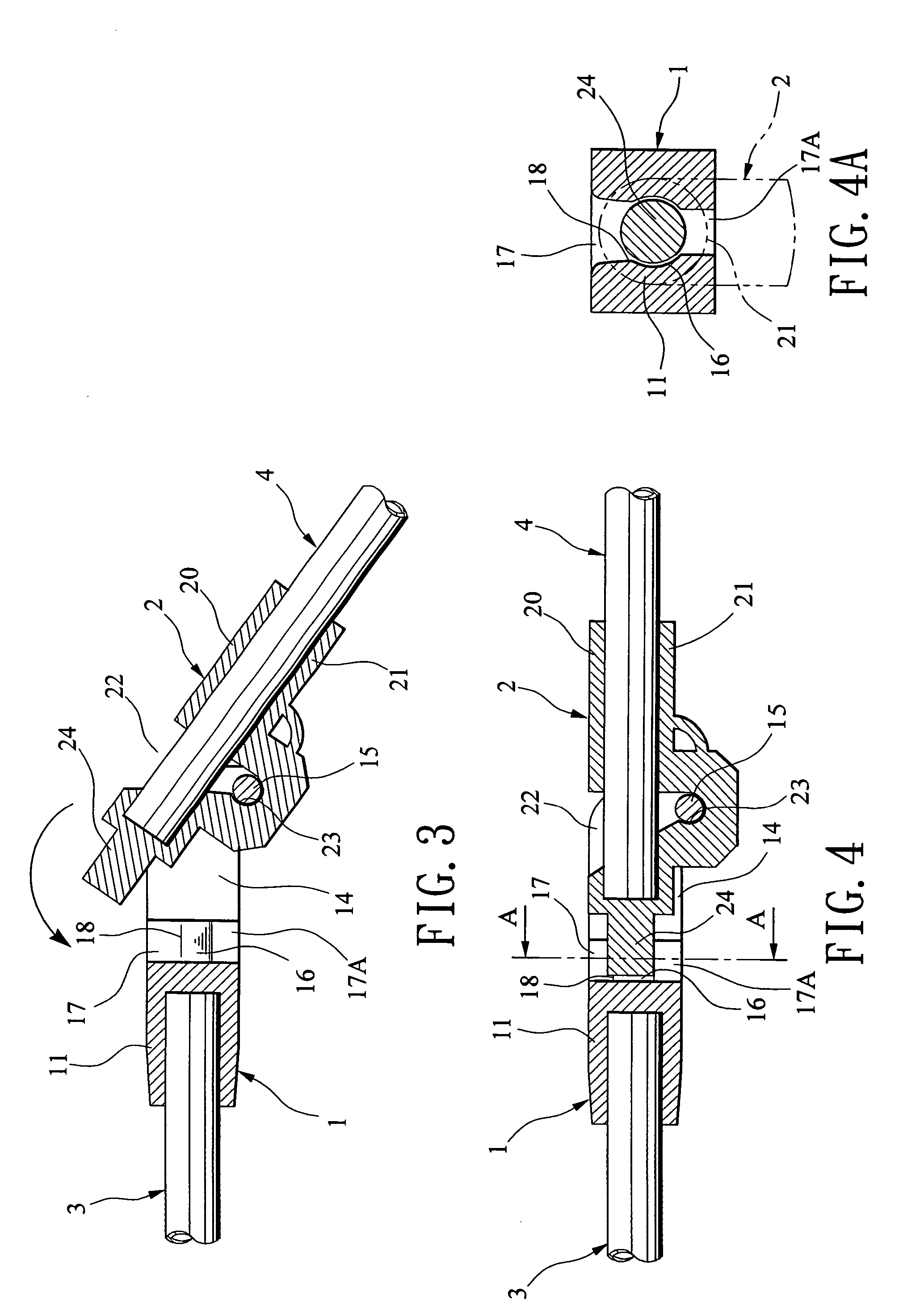

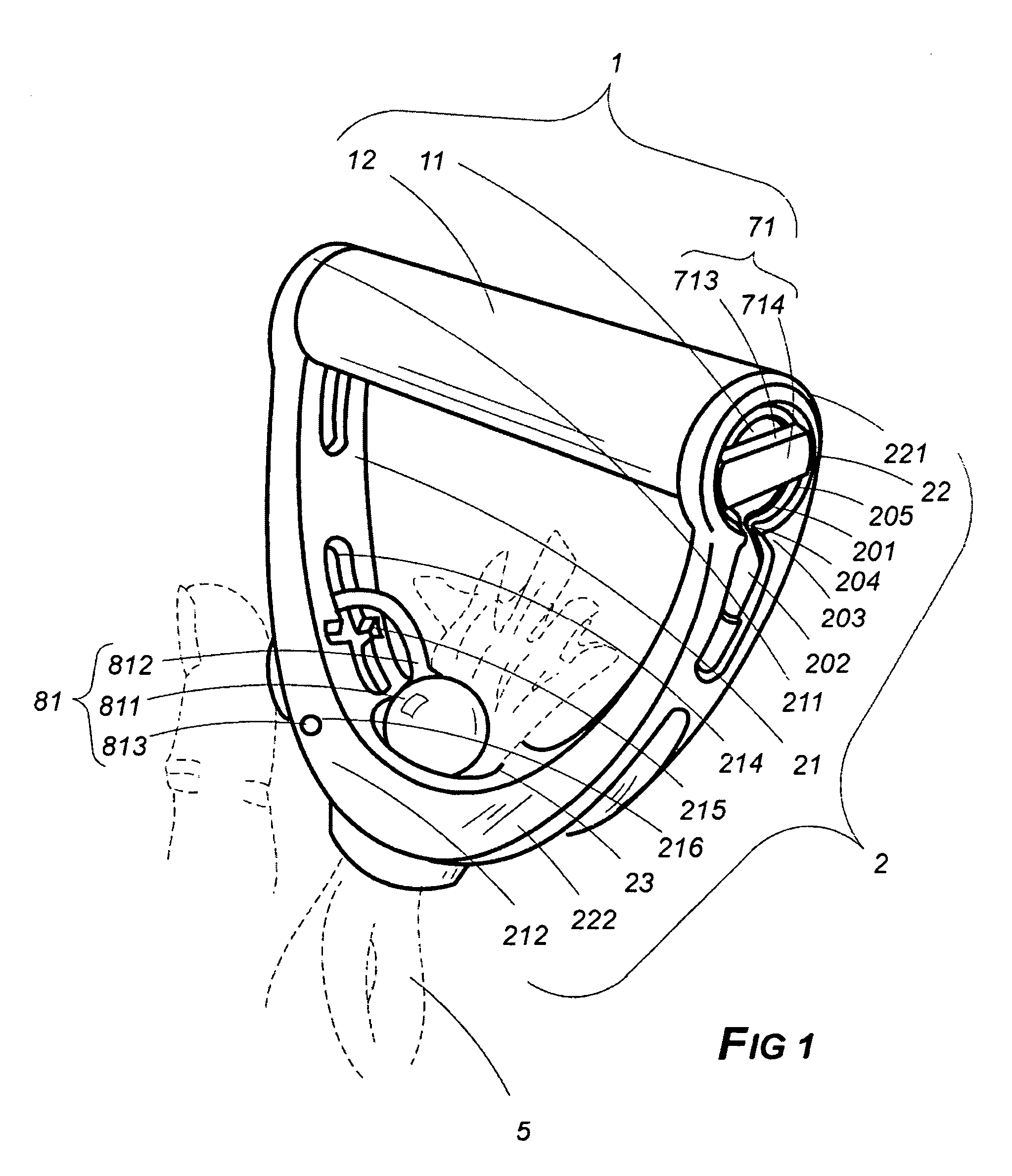

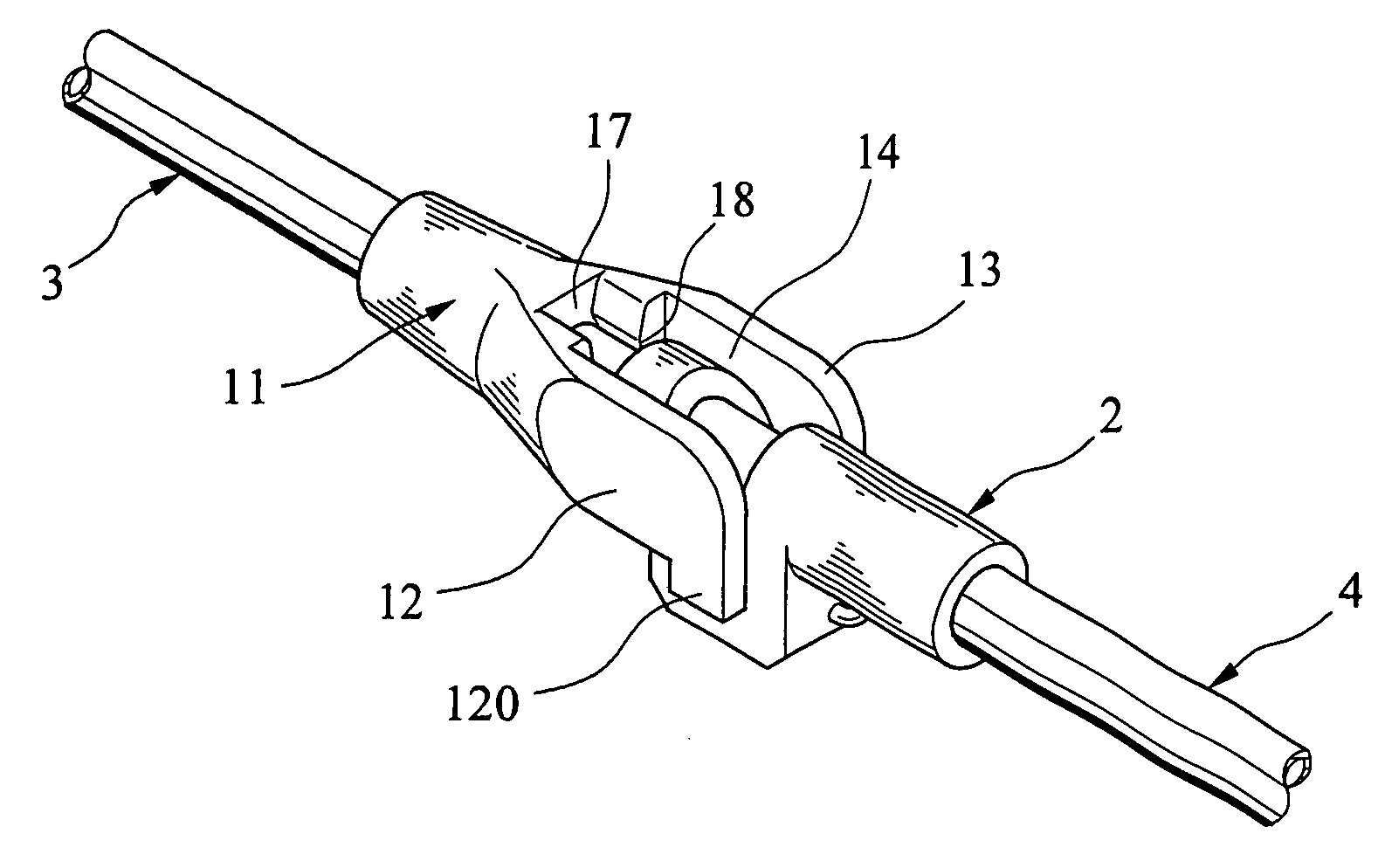

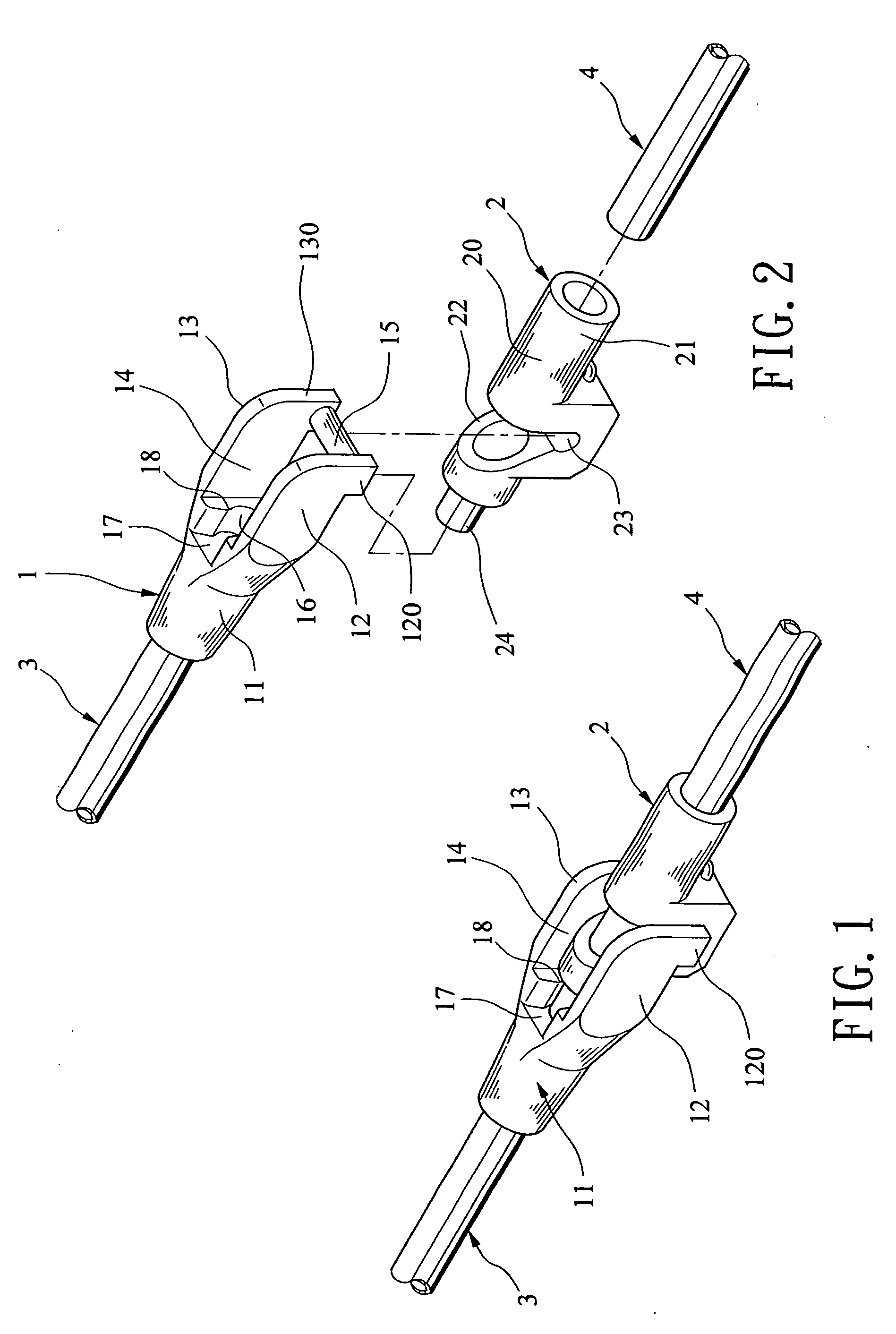

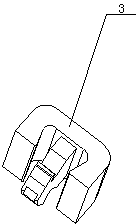

Hinge coupling

Disclosed is a hinge coupling comprising a first connective section comprising a hollow first cylinder at one end with a first piece fastened therein, two parallel projections at the other end, each projection having a bent end, a bore in an intermediate portion open to the external, and a bar interconnected the bent ends, the bar being not aligned with rest of the first connective section, and a second connective section comprising an extension at one end, a hollow second cylinder substantially passed from one end to the other end, an intermediate recess, and a groove formed at bottom of the recess. The bar is fastened in the groove by snapping through the recess, a second piece is inserted into the second cylinder by passing over the bar, and the extension is inserted into the bore by counterclockwise pivoting about the bar. Both sections are parallel after folding.

Owner:YOU CHING CHUAN

Keyed handgrip assembly

The handhold of an exercise handgrip turns freely while seated between the open ends of the upwardly extending prongs. It can be easily removed by moving the specially formed end part of the handhold into an access opening wide enough to slip the end part through. In positioning the handhold's end part for this removal, it must be forcibly snapped through a narrow opening. By reversing the procedure, the handhold can easily be returned to its place of rotation. The specially formed end part of the handhold must, therefore, have a narrow neck-like portion to fit through the narrow opening but the end part must also be enlarged to keep it in place for rotation. Preferably, there is also a stem and ball unit in one of the prongs which swings into place to trap exercise sheeting, cord or other media within an opening at the handgrip's bottom portion.

Owner:LIFELINE INT +2

Snap electrode

ActiveUS7245957B2Robust electrical connectionReduce worriesElectroencephalographyElectrocardiographyPower flowAdhesive

A medical snap electrode having a conductive tape portion disposed between the cover material and conduction layer of the electrode. The conductive tape portion becomes part of an electrical connection from a top snap, positioned above the cover material, to the conductive tape then to the conductive layer. The conductive tape includes conductive adhesive on at least one of its surfaces and thereby provides a more robust electrical connection from a top snap to a conductive layer in the electrode and ultimately to a subject's skin. Viewing of the snap through the conductive film layer is prevented. The conductive tape thus provides an improved conduction path for distributing electrical current from the top snap to a subject's skin in addition to the conduction path through bottom snap. The improved conduction path can prevent heating or apprehension of potential heating by a subject or clinician.

Owner:KPR U S LLC

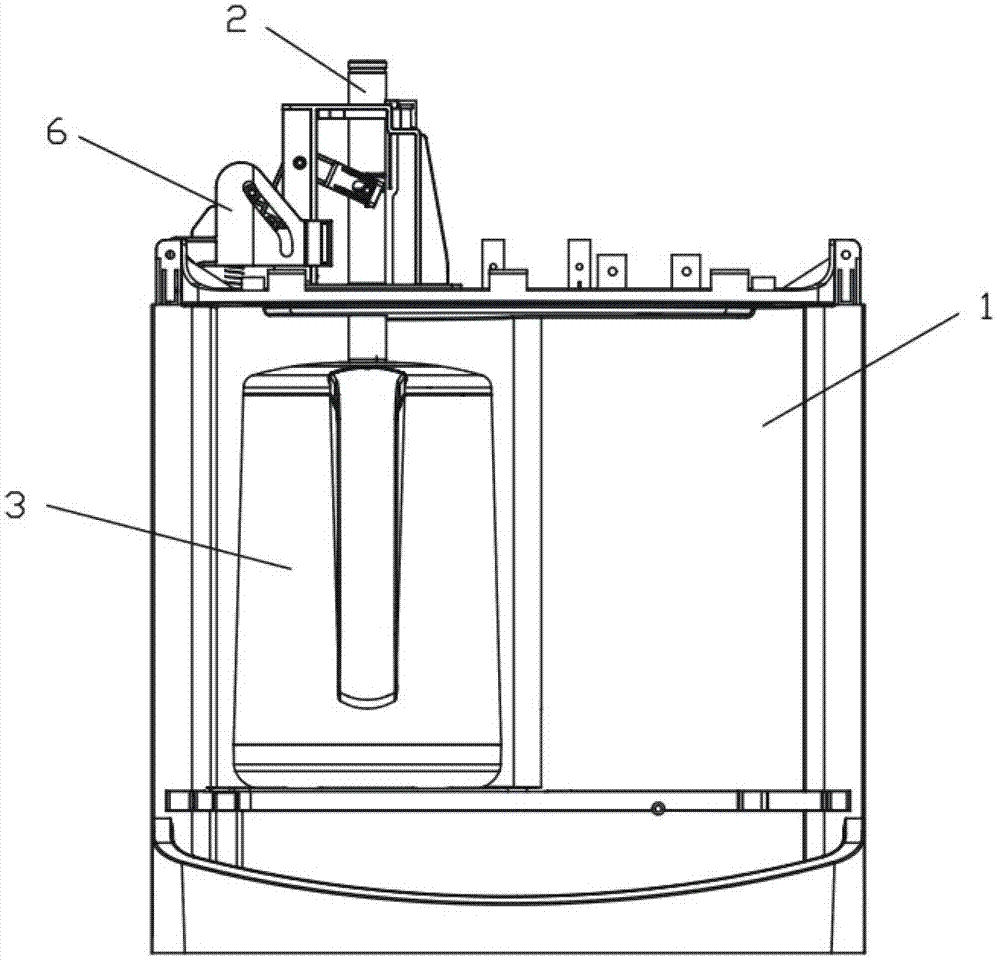

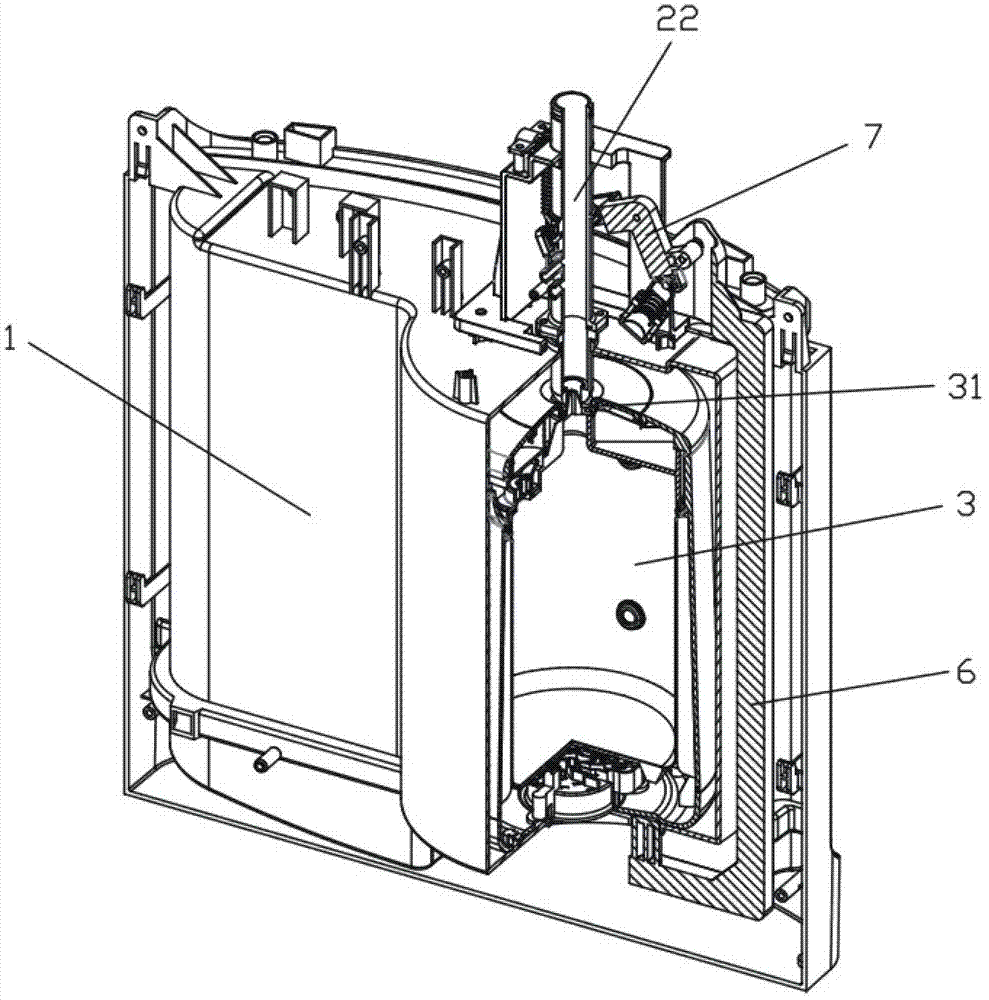

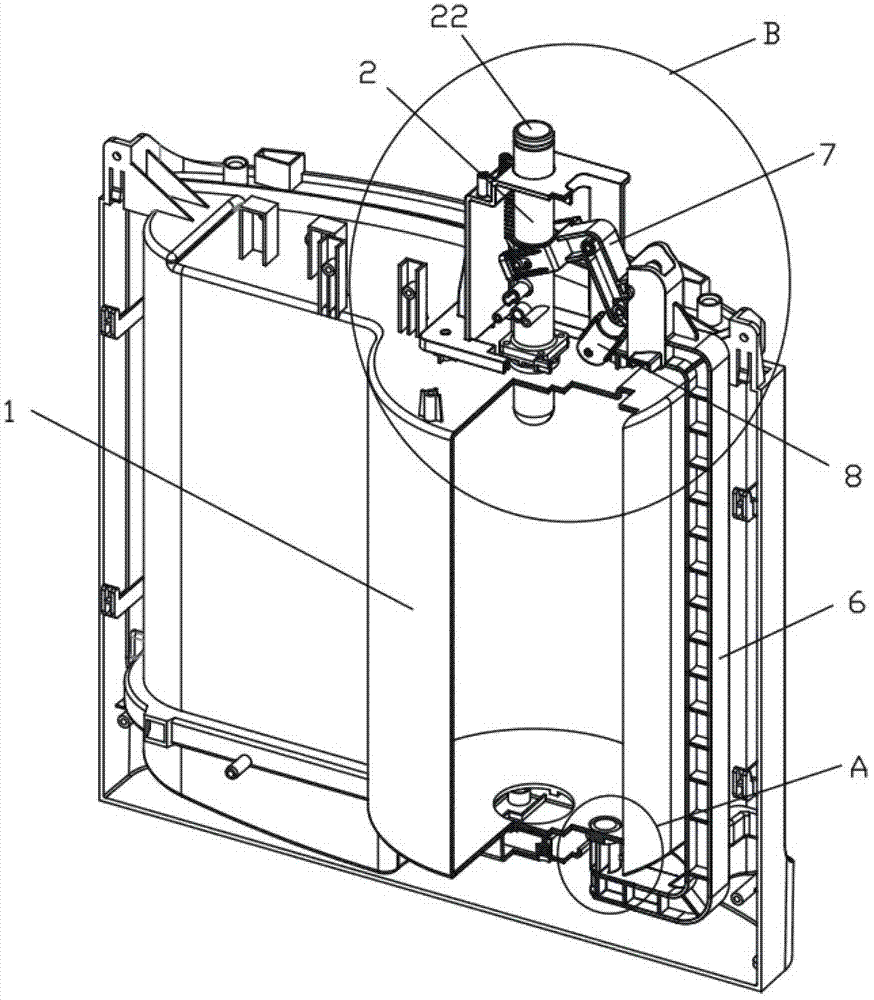

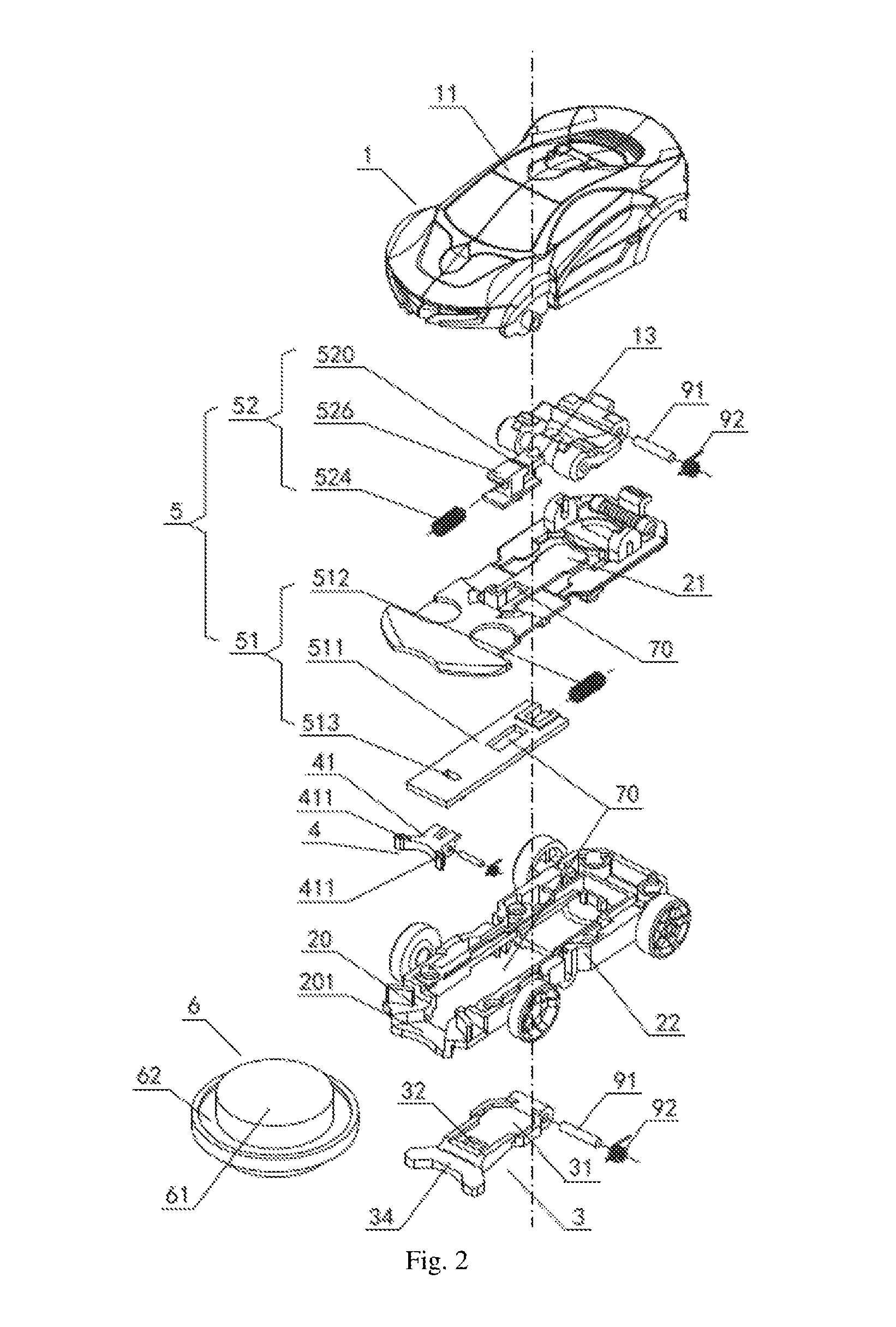

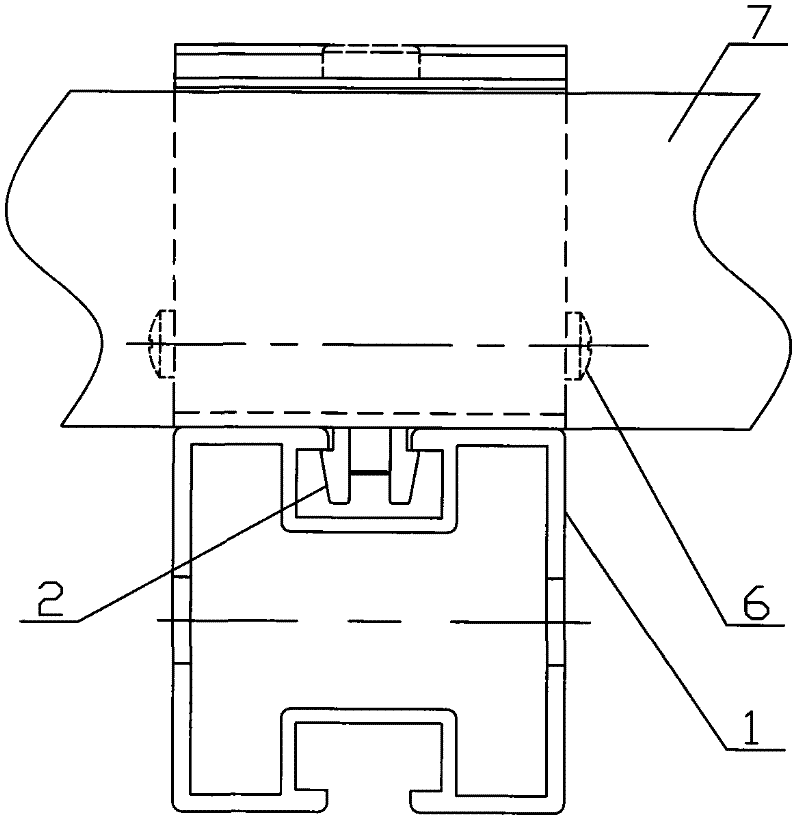

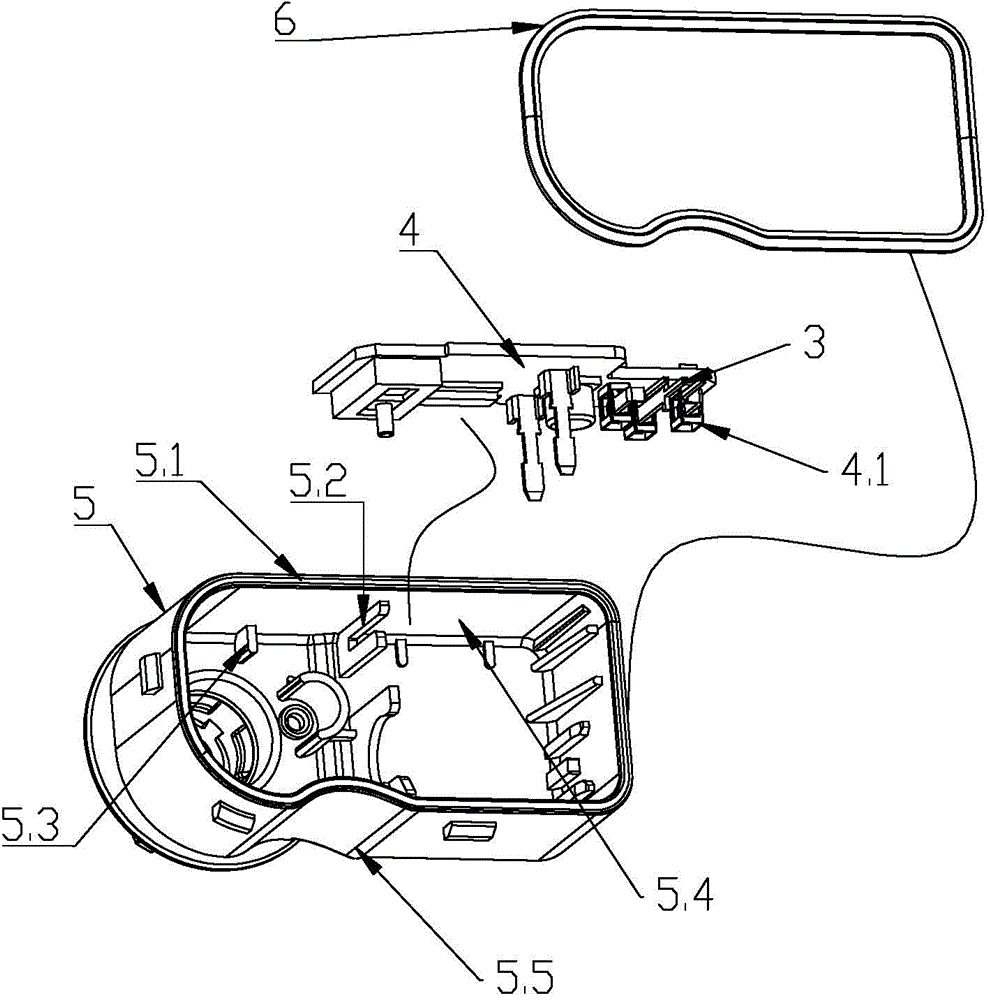

Water dispenser capable of conveniently taking and placing water kettle

The invention relates to a water dispenser capable of conveniently taking and placing a water kettle. The water dispenser comprises a water kettle with a water injection port, a panel for placing the water kettle, a water injection rod for injecting water into the water kettle, a support with the water injection rod, and a pull rod touched by the water kettle, wherein a guide hole capable of allowing the water injection rod to move up and down is arranged on the support, and the pull rod is connected with the water injection rod through a snap-through mechanism comprising a snap-through lever and a snap-through spring; the snap-through lever is connected with the pull rod through a slide pair, and the water kettle pushes the pull rod to move downwards to drive the snap-through lever to rotate around a fulcrum of the snap-through lever; the snap-through lever is connected with the water injection rod through a shifting fork pair, and the snap-through lever rotates to shift the water injection rod to move up and down; one end of the snap-through spring is connected with the snap-through lever, and the other end of the snap-through spring is arranged on the support; and when the snap-through lever goes over an equilibrium position, the snap-through spring is released and drive the snap-through lever to fast unbalance.

Owner:JOYOUNG CO LTD

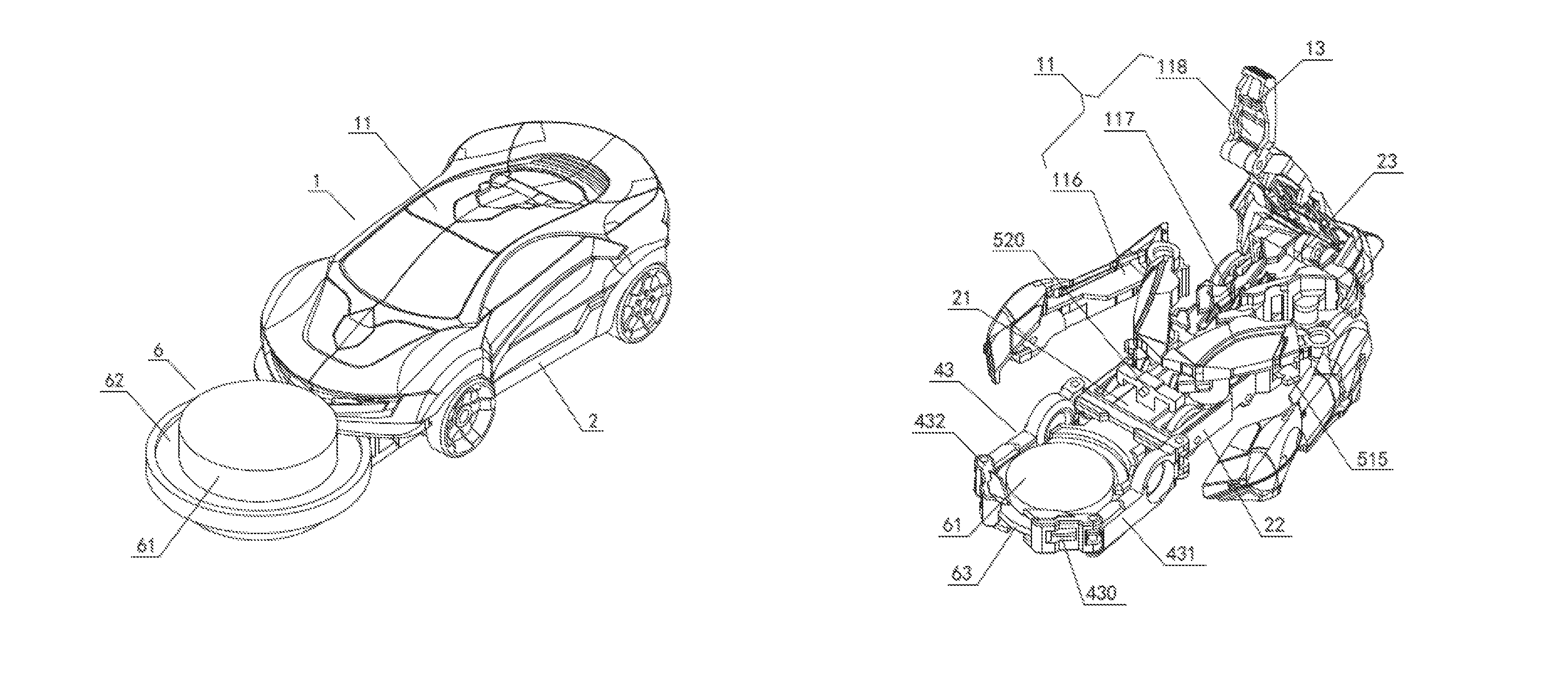

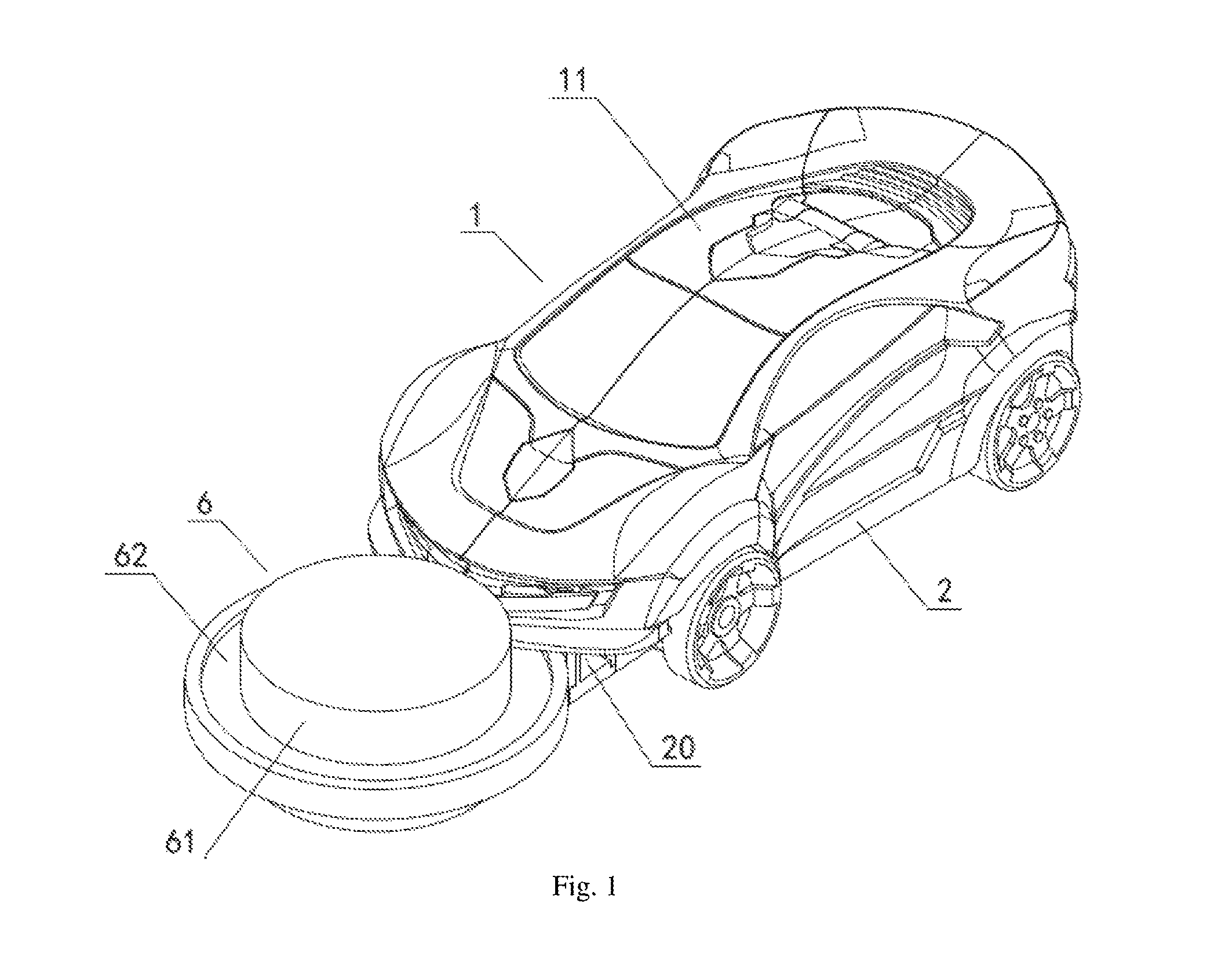

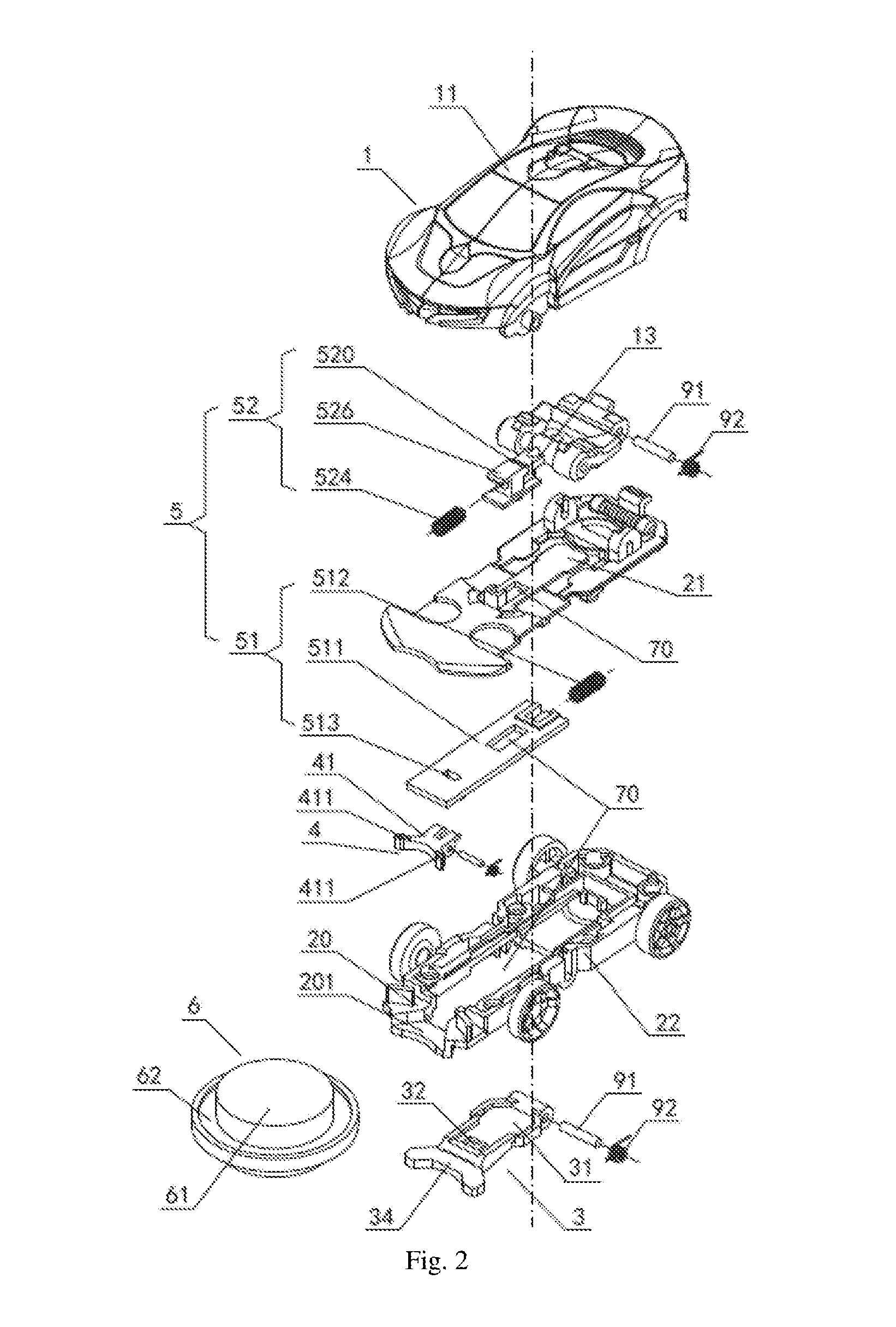

Flipping and transforming toy vehicle capable of gripping toys

Owner:ALPHA GRP CO LTD +2

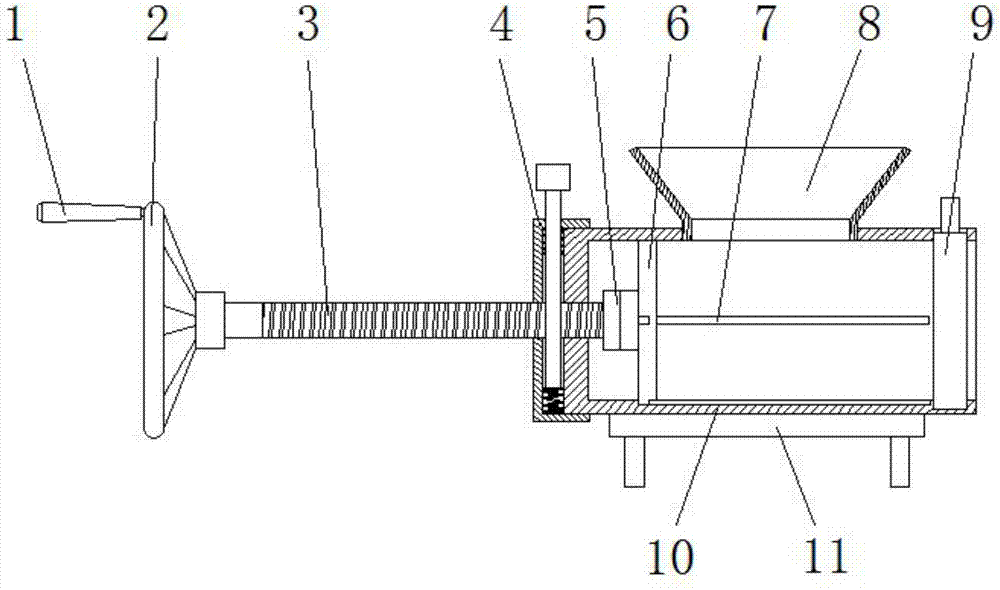

Manual fruit strip-cutter

InactiveCN107234641AEasy to replaceSimple structureMetal working apparatusAgricultural engineeringSnap through

The invention discloses a manual fruit slicer, which comprises an extruding sleeve, a cutting knife is movably installed in the inner cavity at the right end of the extruding sleeve, and the middle inner cavity of the extruding sleeve moves through a chute An extruding plate is installed, and the middle part of the left side of the extruding plate is rotatably connected with the screw through a rotating joint. The left end of the screw runs through the extruding sleeve and the quick return device and is fixedly equipped with a hand wheel. The outer side of the hand wheel A rotary handle is installed for rotation, and the quick return device includes a housing, and an upper buckle and a lower buckle are fixedly connected to the inner cavity of the middle part of the housing through a spring, and the two sides of the lower buckle are connected by a gear and a straight rack. The upper end of the spur rack is fixedly connected with a handle. The invention is simple in structure, convenient and practical, and effectively improves the use effect of the device. At the same time, it adopts a quick return device, which can quickly return the device to the state to be cut after the cutting is completed, which can effectively save manpower and improve the cutting efficiency. .

Owner:徐远洋

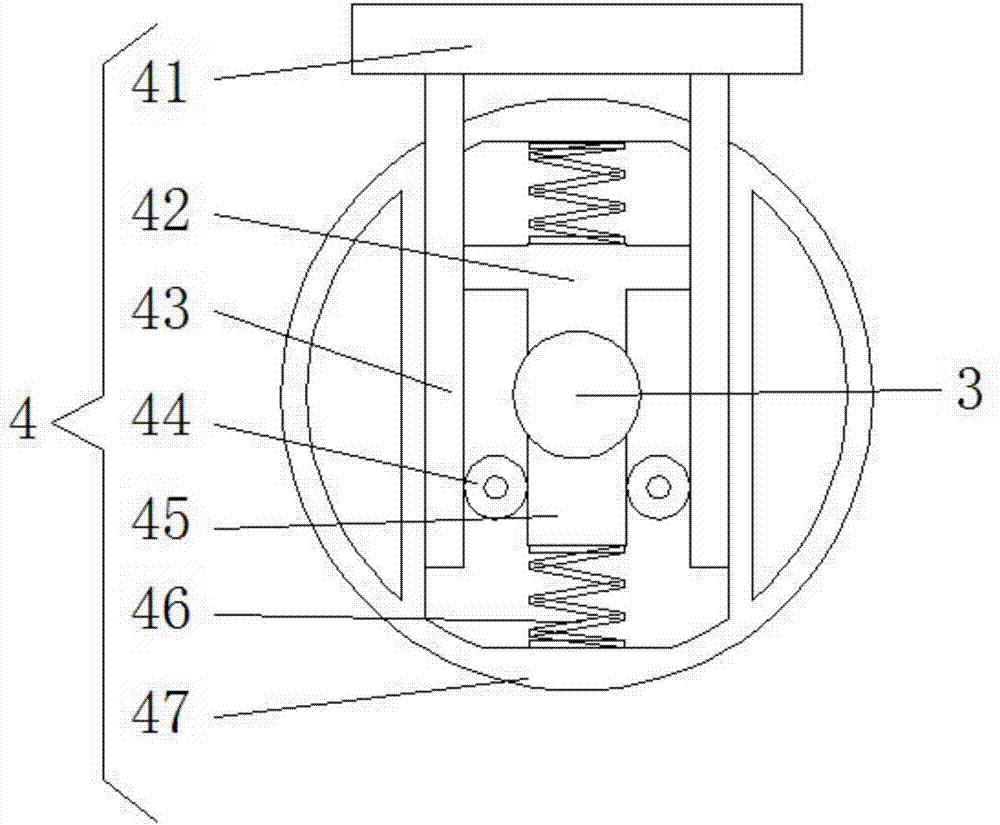

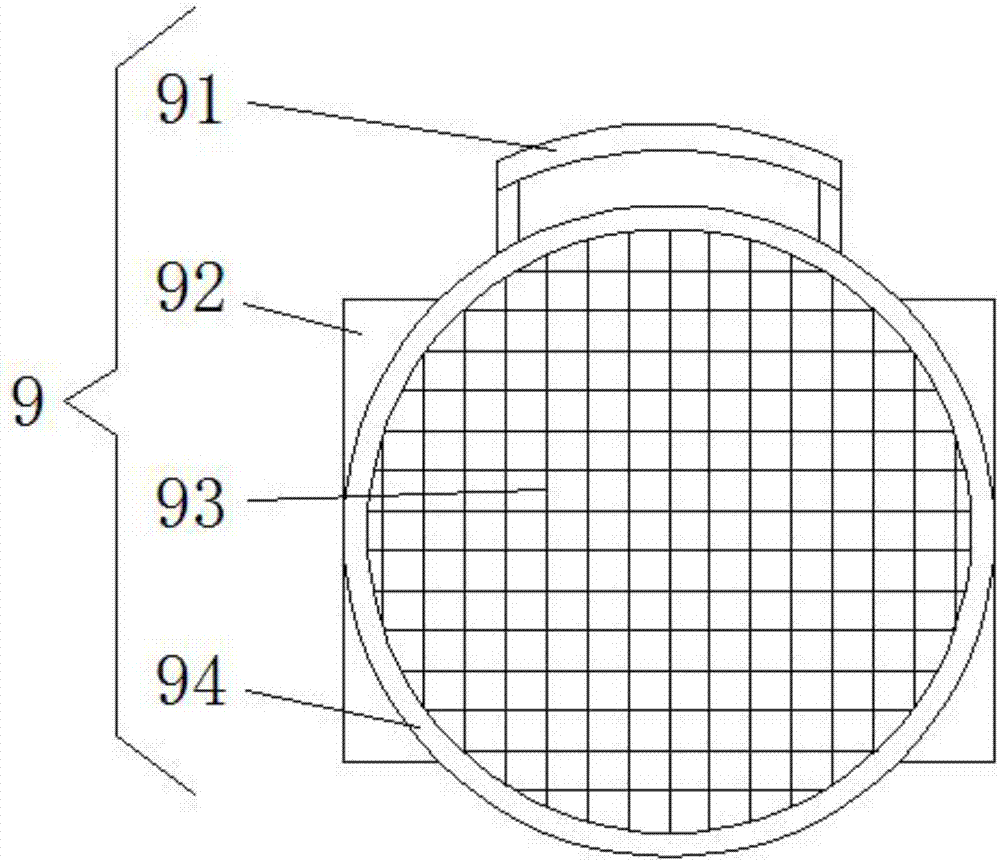

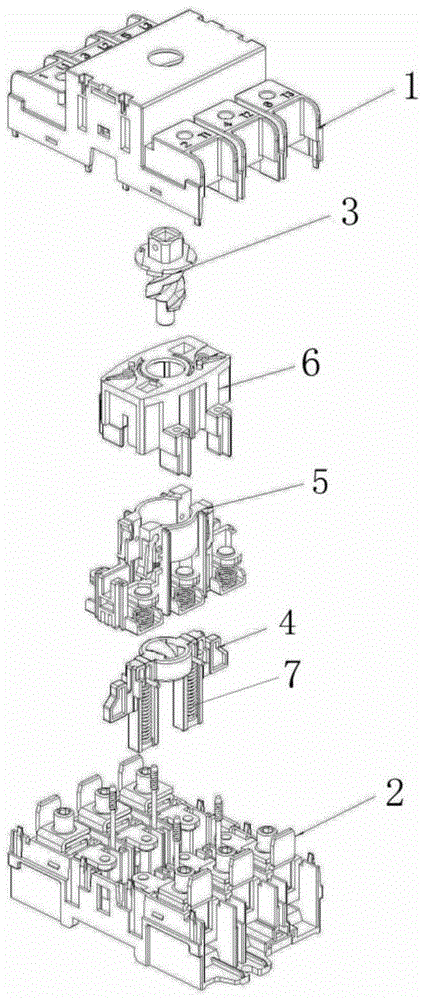

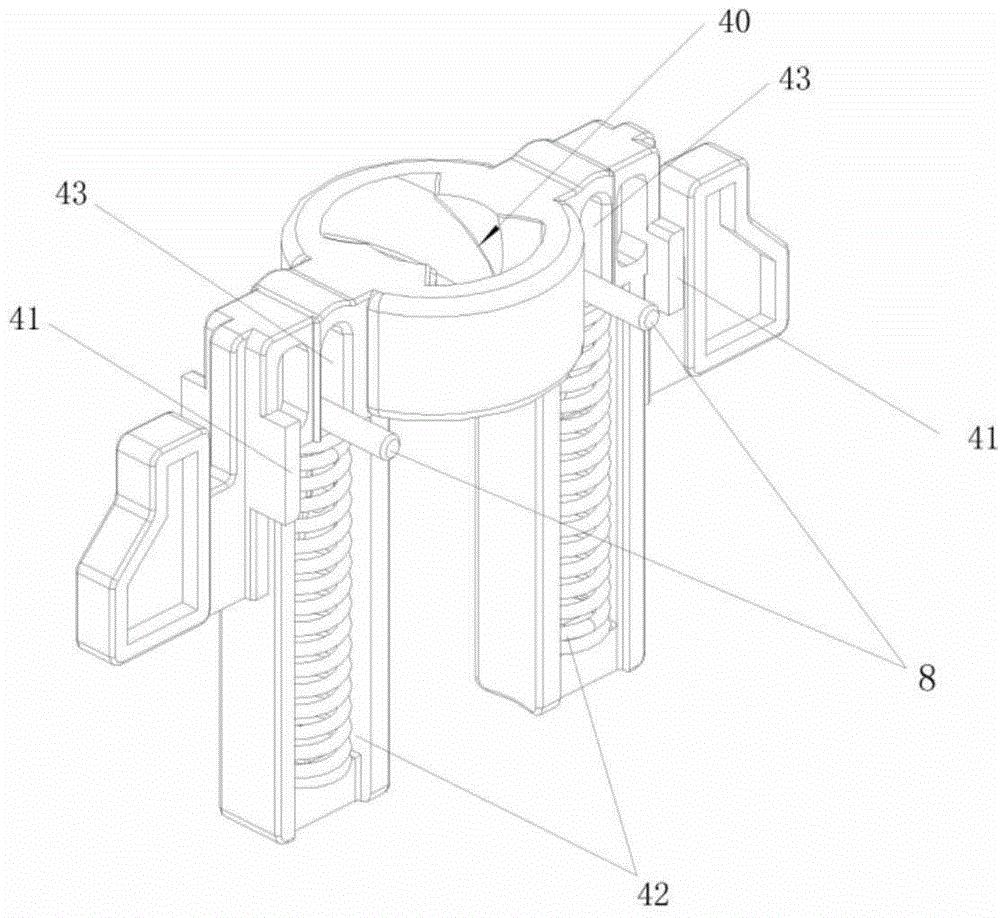

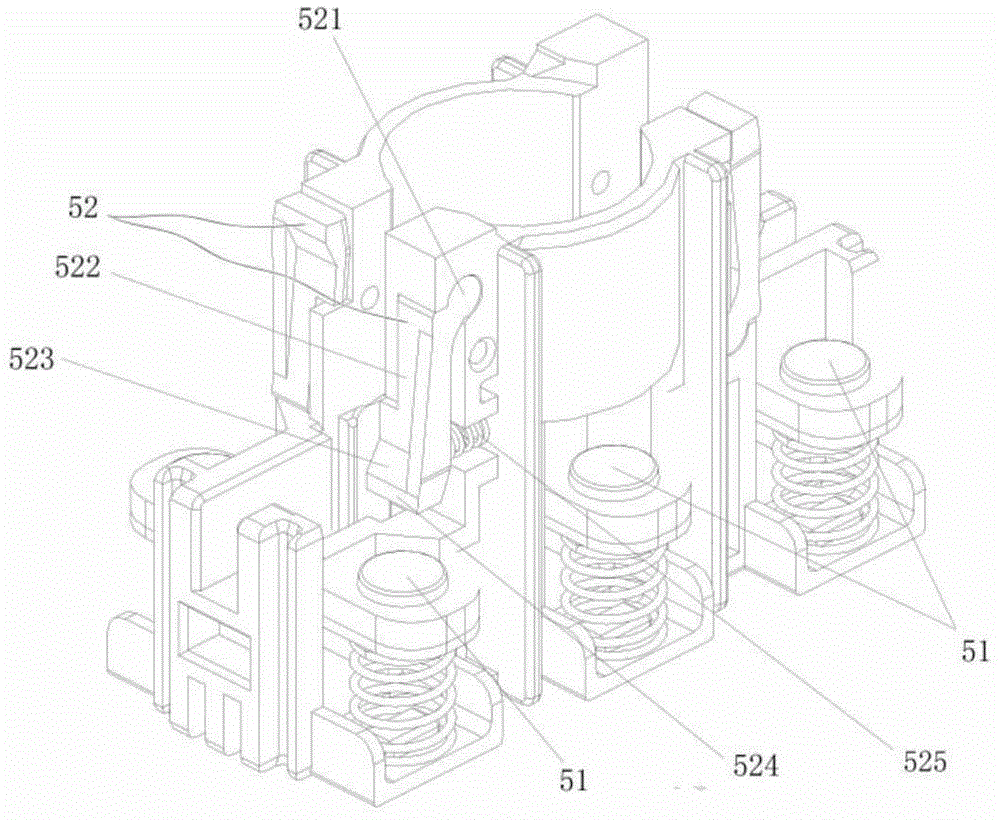

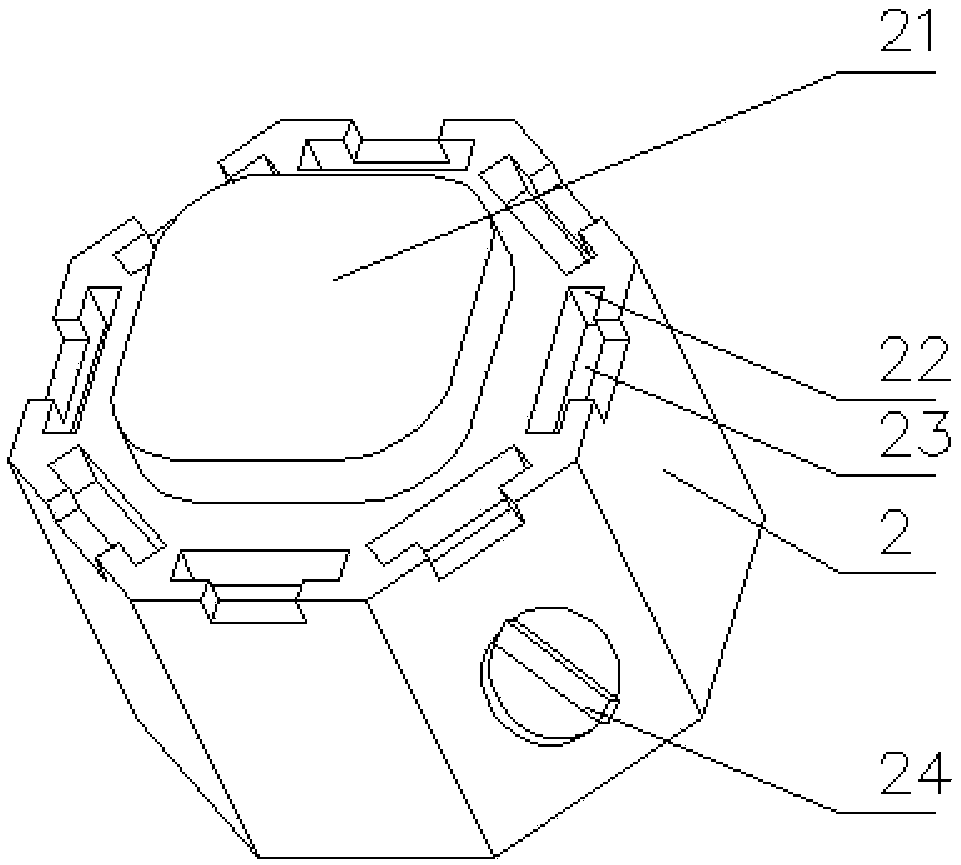

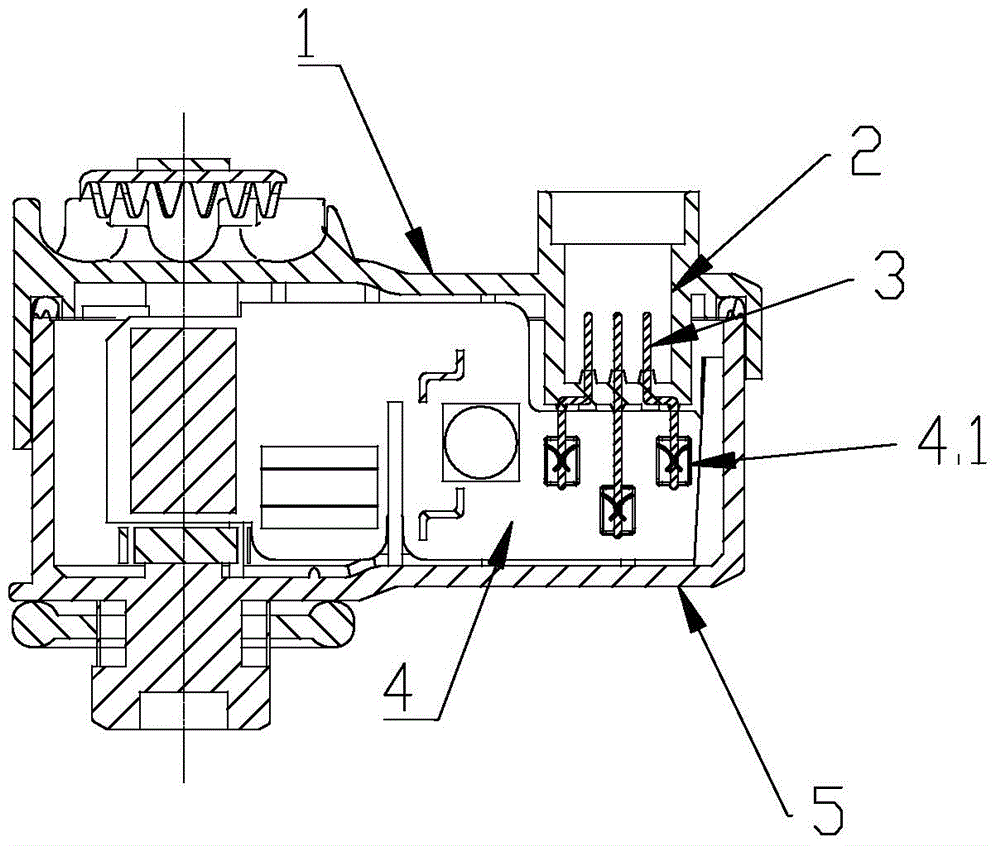

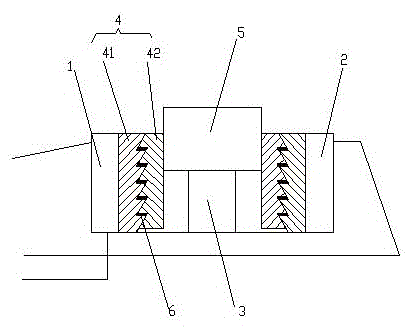

Snap-through rotary switch

The invention relates to a snap-through rotary switch. A locking device is arranged on a moving contact frame, a locking structure is arranged on a middle seat; an unlocking device and an elastic assembly are arranged between a movable frame and the moving contact frame; when a rotary assembly rotates within a threshold value range, the moving contact frame is locked on the middle seat under cooperation of the locking device and the locking structure, and the movable frame moves relative to the moving contact frame to compress the elastic assembly so that the elastic assembly can store energy; when the rotary assembly rotates to a threshold value point, the unlocking device drives the locking device to break away from the locking structure, and the moving contact frame moves under the energy storage action of the elastic assembly to drive a moving contact to make contact with or break away from a static contact. The elastic assembly serving as an energy storage device is matched with the locking device and the unlocking device, the moving contact can rapidly break away from or make contact with the static contact, and therefore the contacting force of the moving contact and the static contact of the snap-through rotary switch is stable.

Owner:KEDU ELECTRIC CO LTD

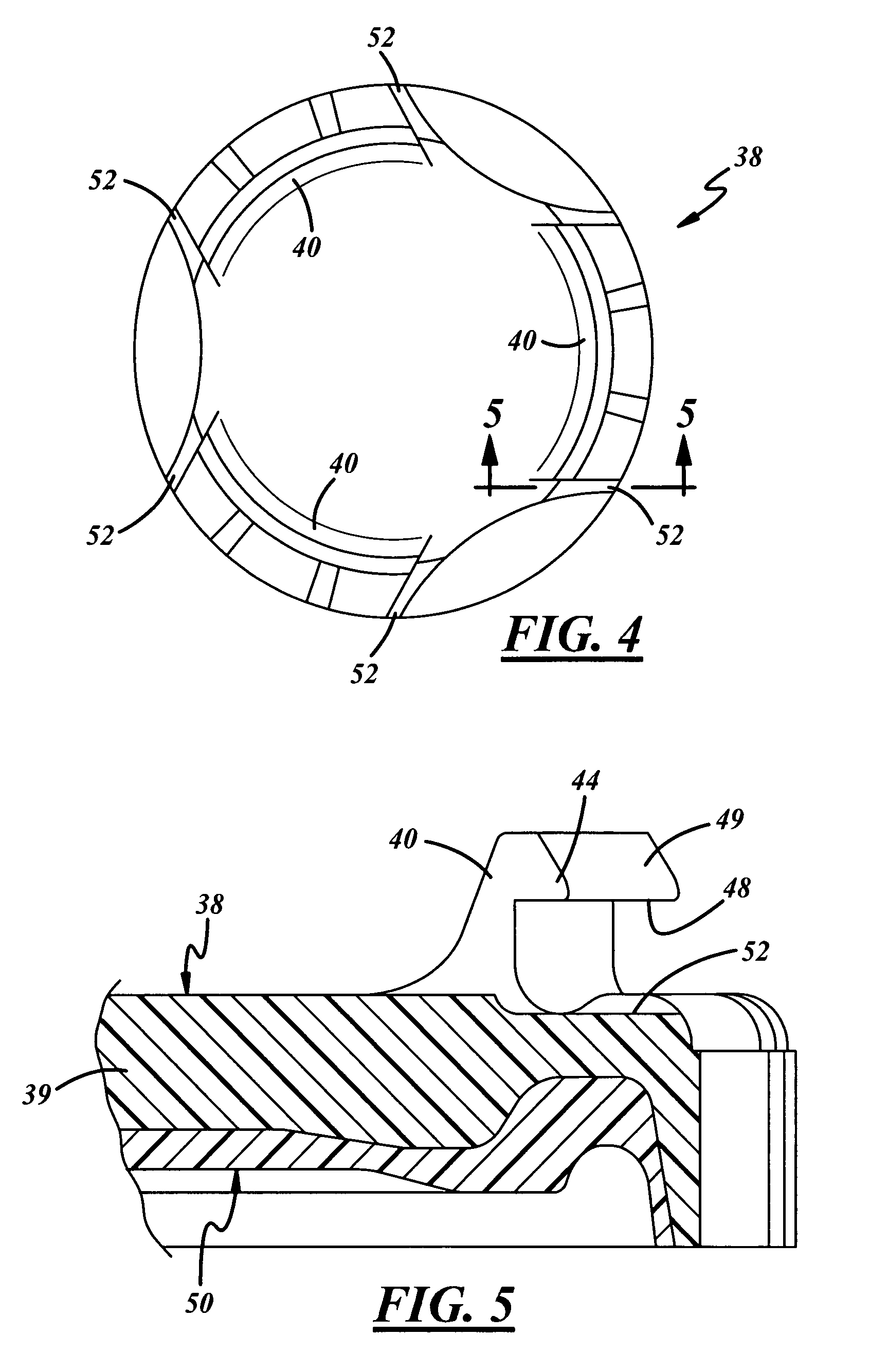

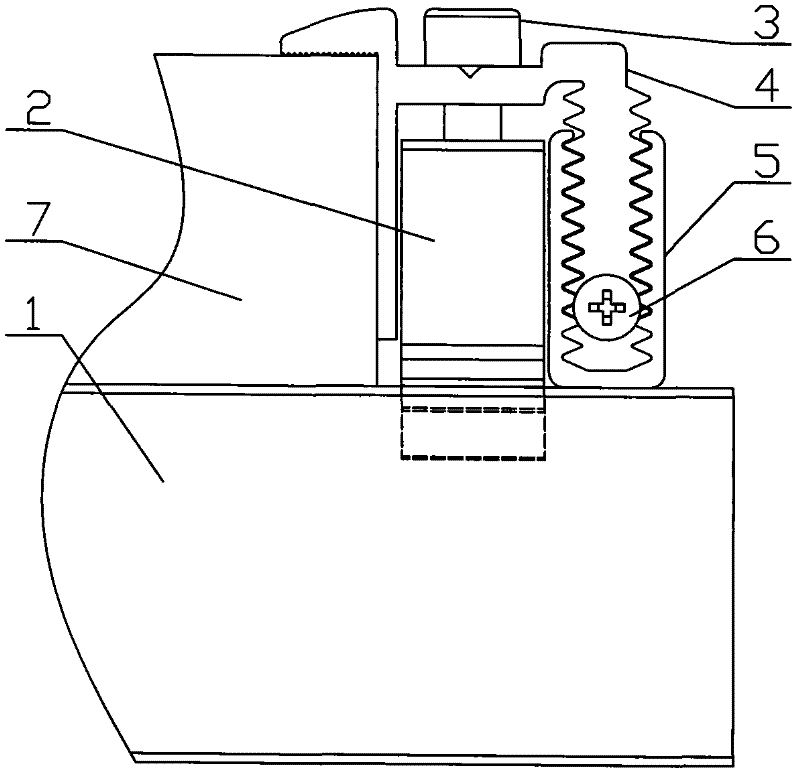

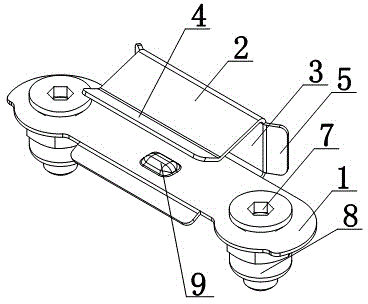

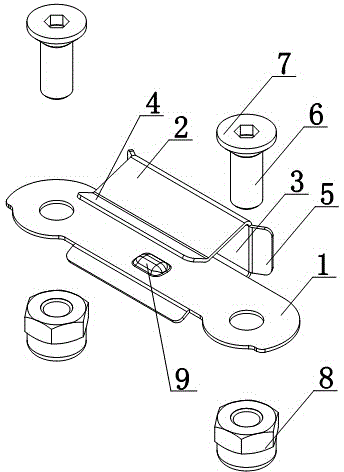

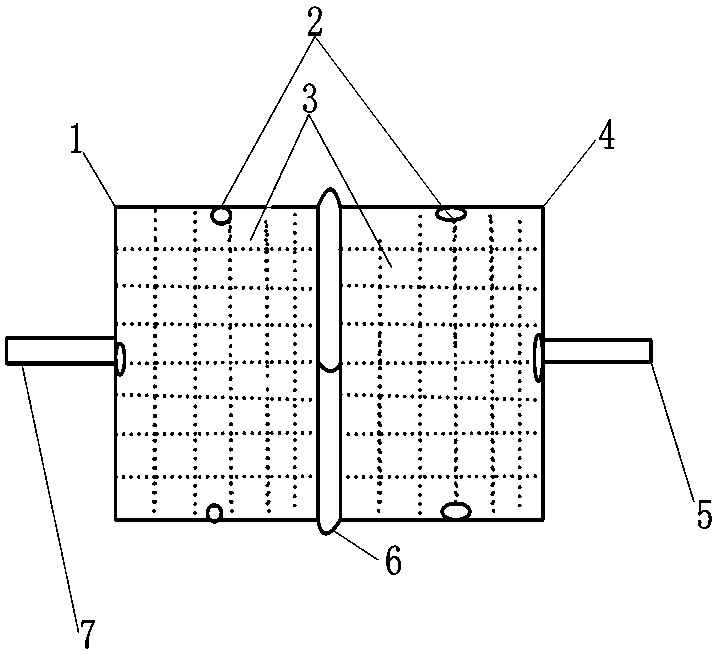

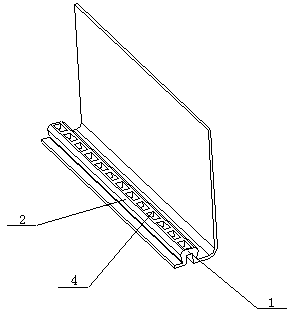

Fixing mechanism for solar panels

InactiveCN102263149AImprove general performanceQuick installationSolar heating energyPhotovoltaic energy generationCoding blockEngineering

The invention discloses a fixing mechanism for a solar battery panel, which includes a guide rail, on which a buckle is installed, and the buckle is stuck in a slide groove of the guide rail through the slight deformation of two hooks provided on the guide rail. The buckle connects the middle part of the side press code through bolts. One end of the side press code adopts an inverted L-shaped structure that presses the solar panel on the guide rail, and the other end adopts a rack-shaped structure, and the side is inserted with matching teeth. In the edge pressing seat of the shaped groove. According to the thickness of the solar panel, adjust the tooth-shaped matching position of the side pressing code and the side pressing code seat, which can adapt to various specifications of solar panels and has the advantage of strong versatility; In the groove, insert the side pressing code into the side pressing code seat, and then connect and fasten with the buckle through bolts, which is quick to install and simple in structure.

Owner:SAMIL POWER

Snap electrode

ActiveUS20050101853A1RobustRobust electrical connectionElectroencephalographyElectrocardiographyElectricityPower flow

A medical snap electrode having a conductive tape portion disposed between the cover material and conduction layer of the electrode. The conductive tape portion becomes part of an electrical connection from a top snap, positioned above the cover material, to the conductive tape then to the conductive layer. The conductive tape includes conductive adhesive on at least one of its surfaces and thereby provides a more robust electrical connection from a top snap to a conductive layer in the electrode and ultimately to a subject's skin. Viewing of the snap through the conductive film layer is prevented. The conductive tape thus provides an improved conduction path for distributing electrical current from the top snap to a subject's skin in addition to the conduction path through bottom snap. The improved conduction path can prevent heating or apprehension of potential heating by a subject or clinician.

Owner:KPR U S LLC

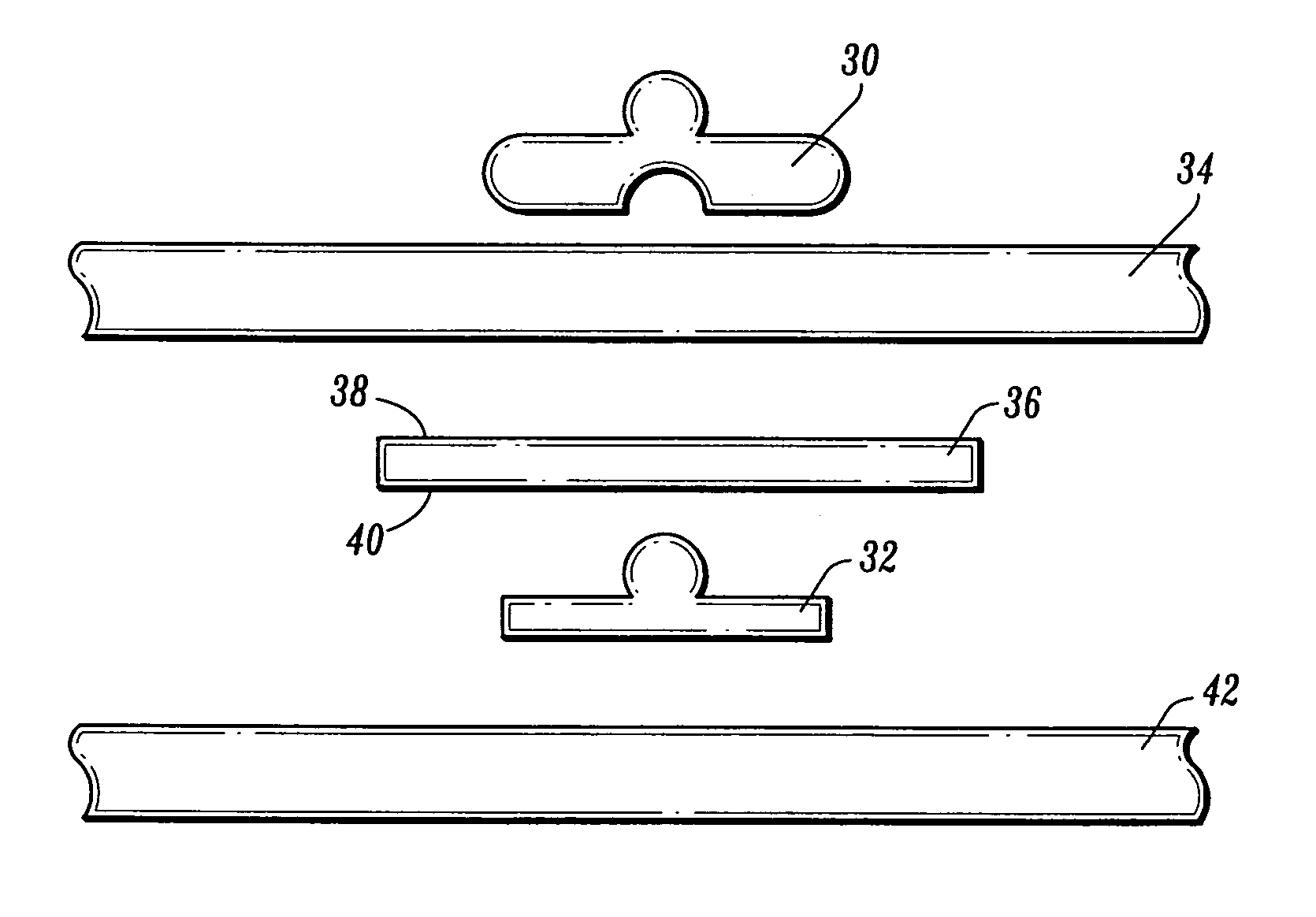

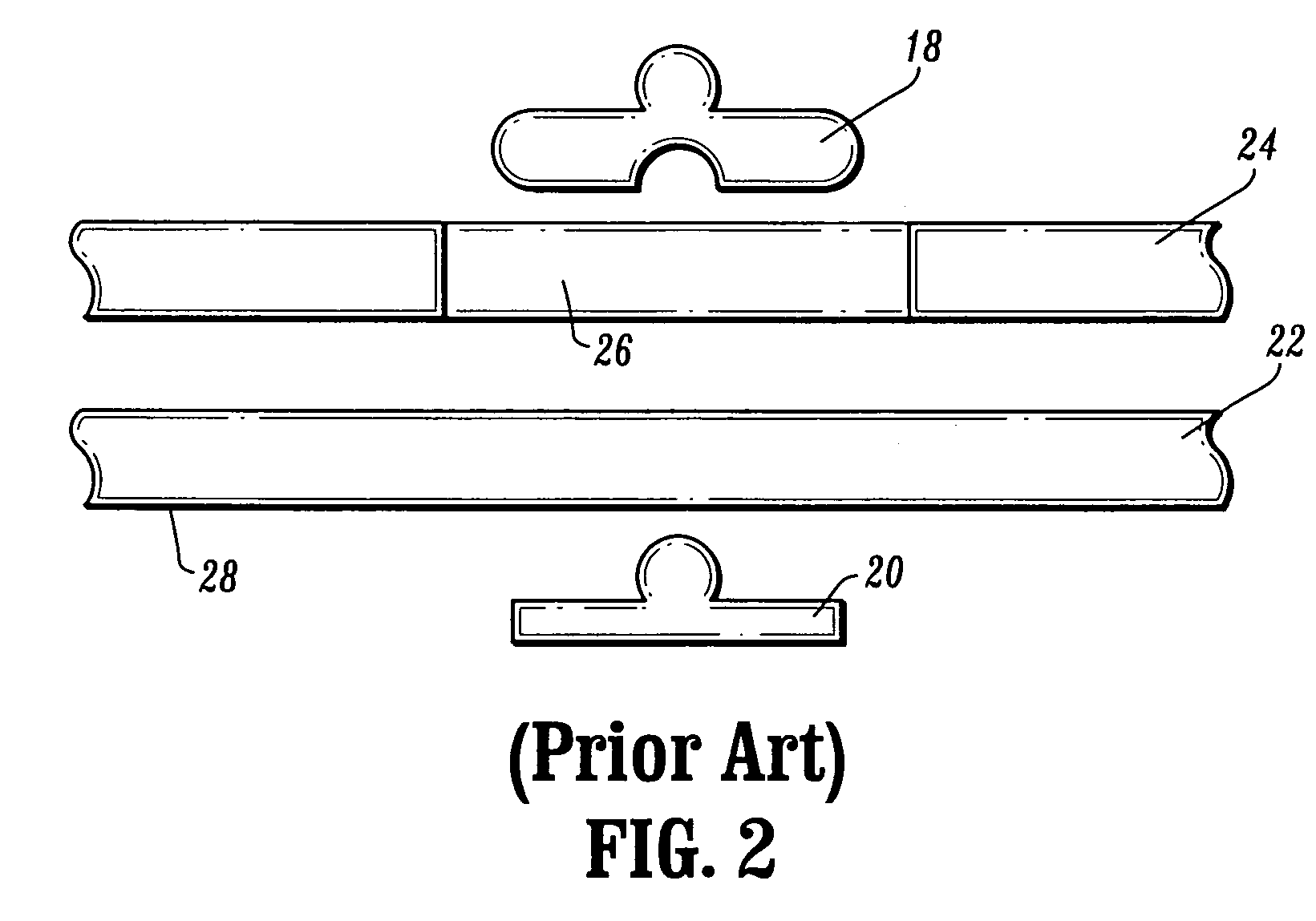

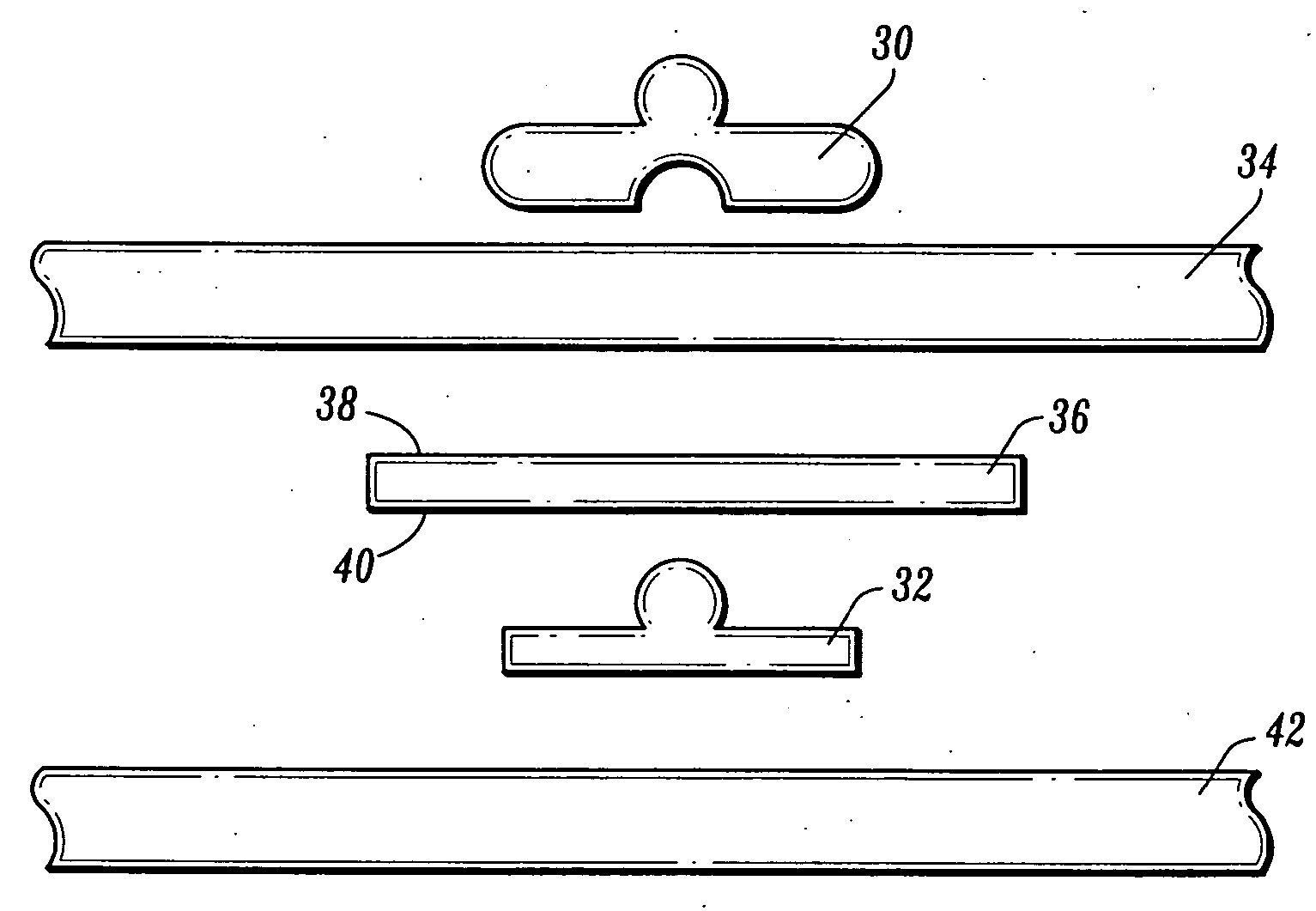

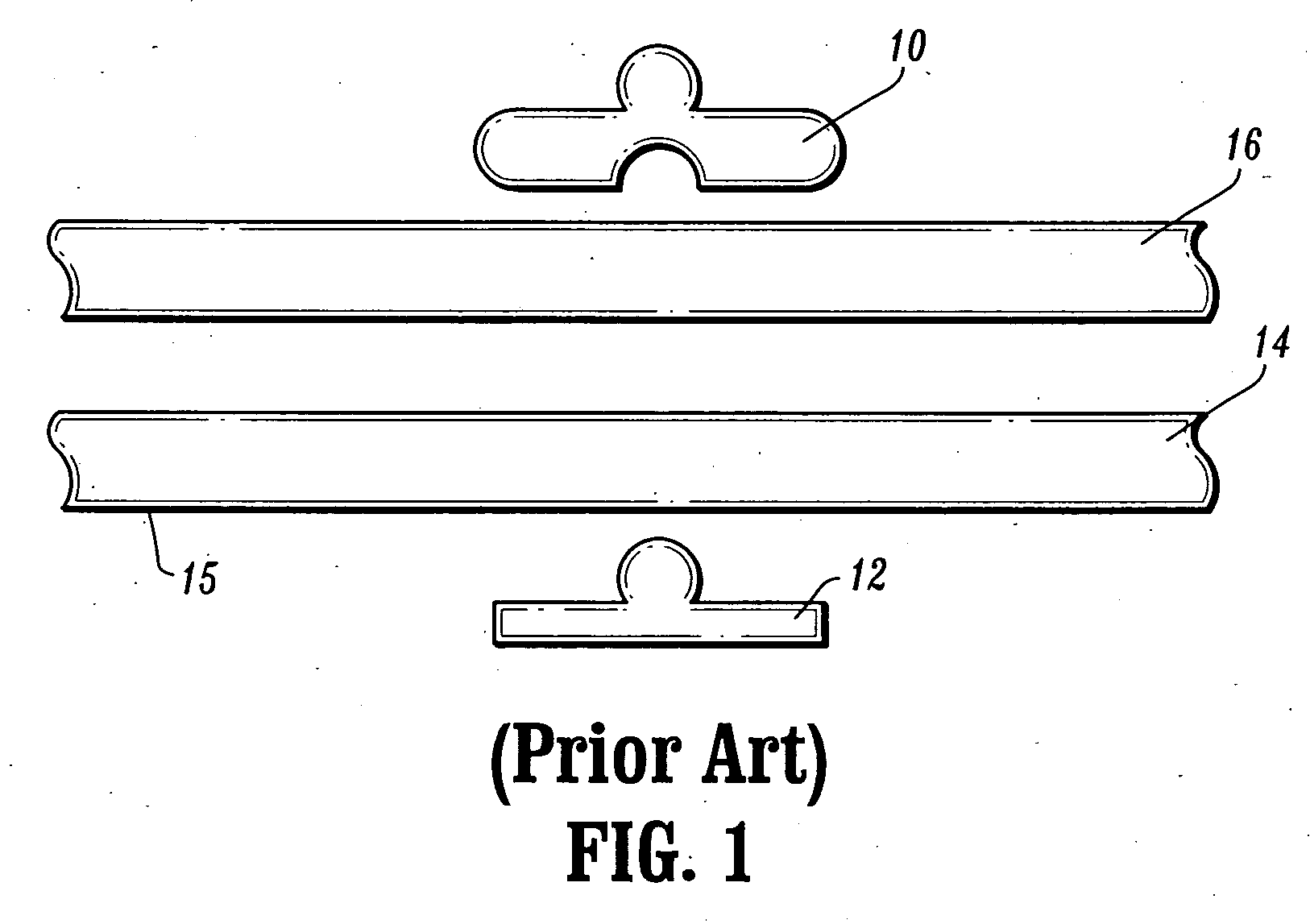

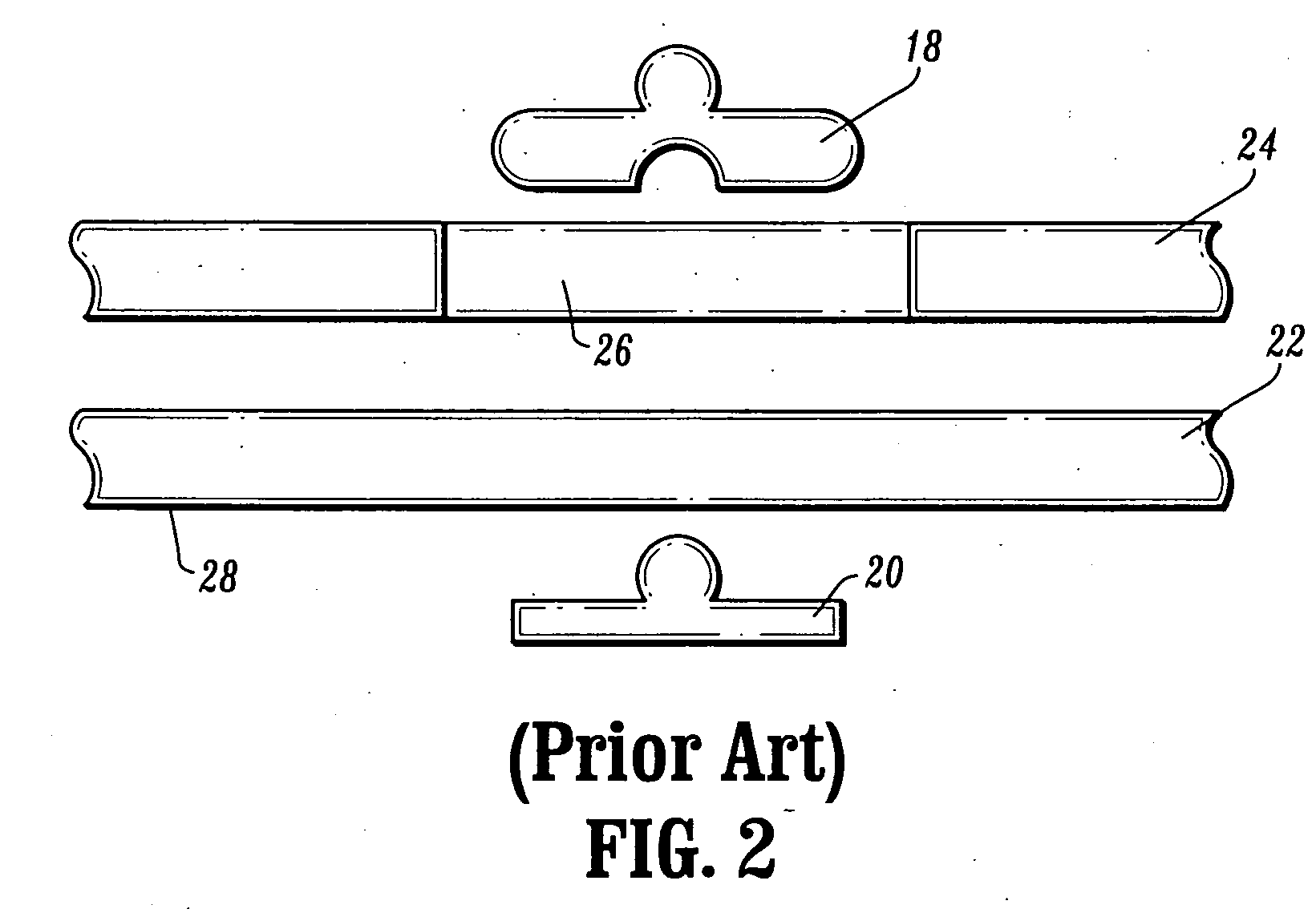

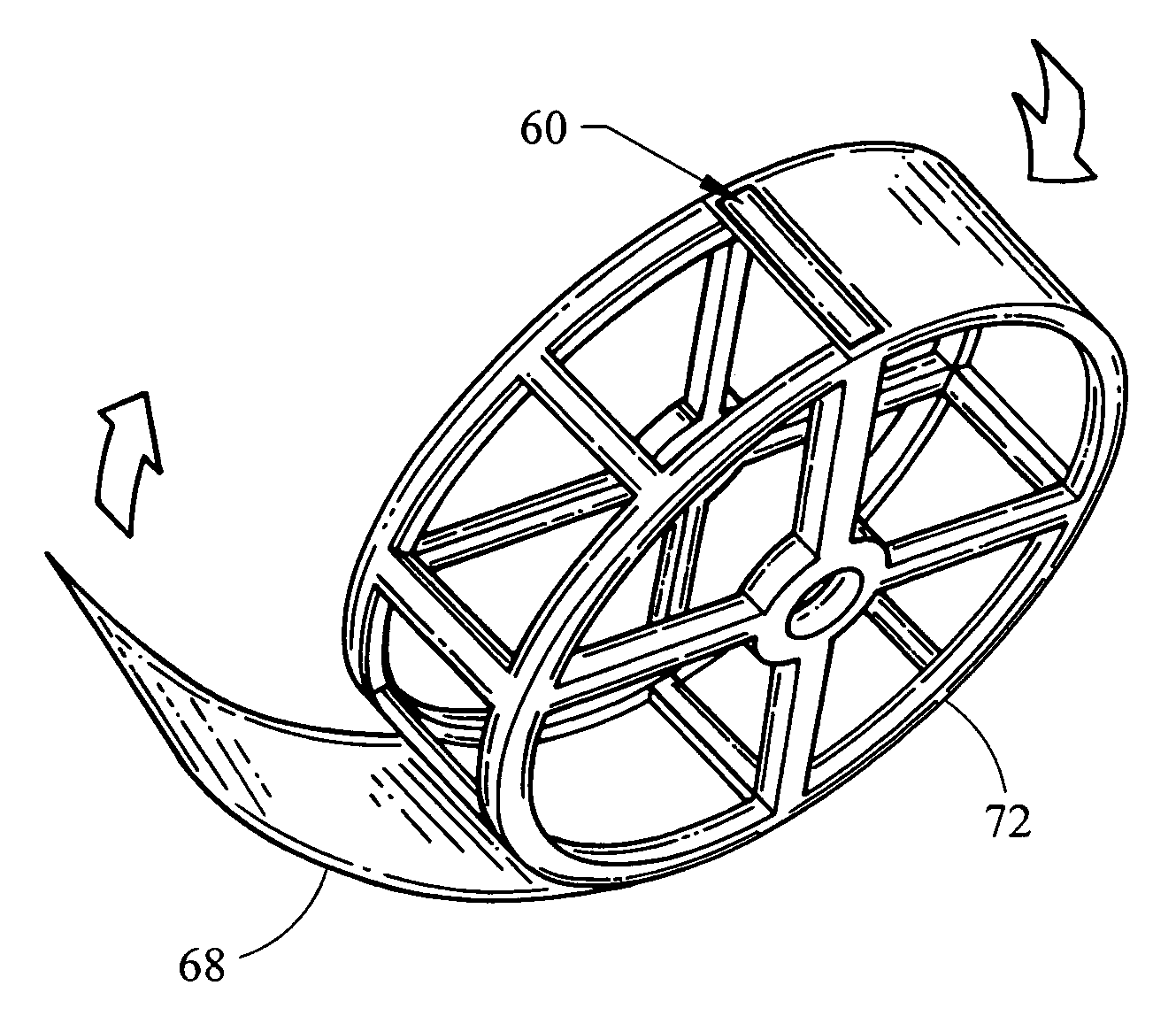

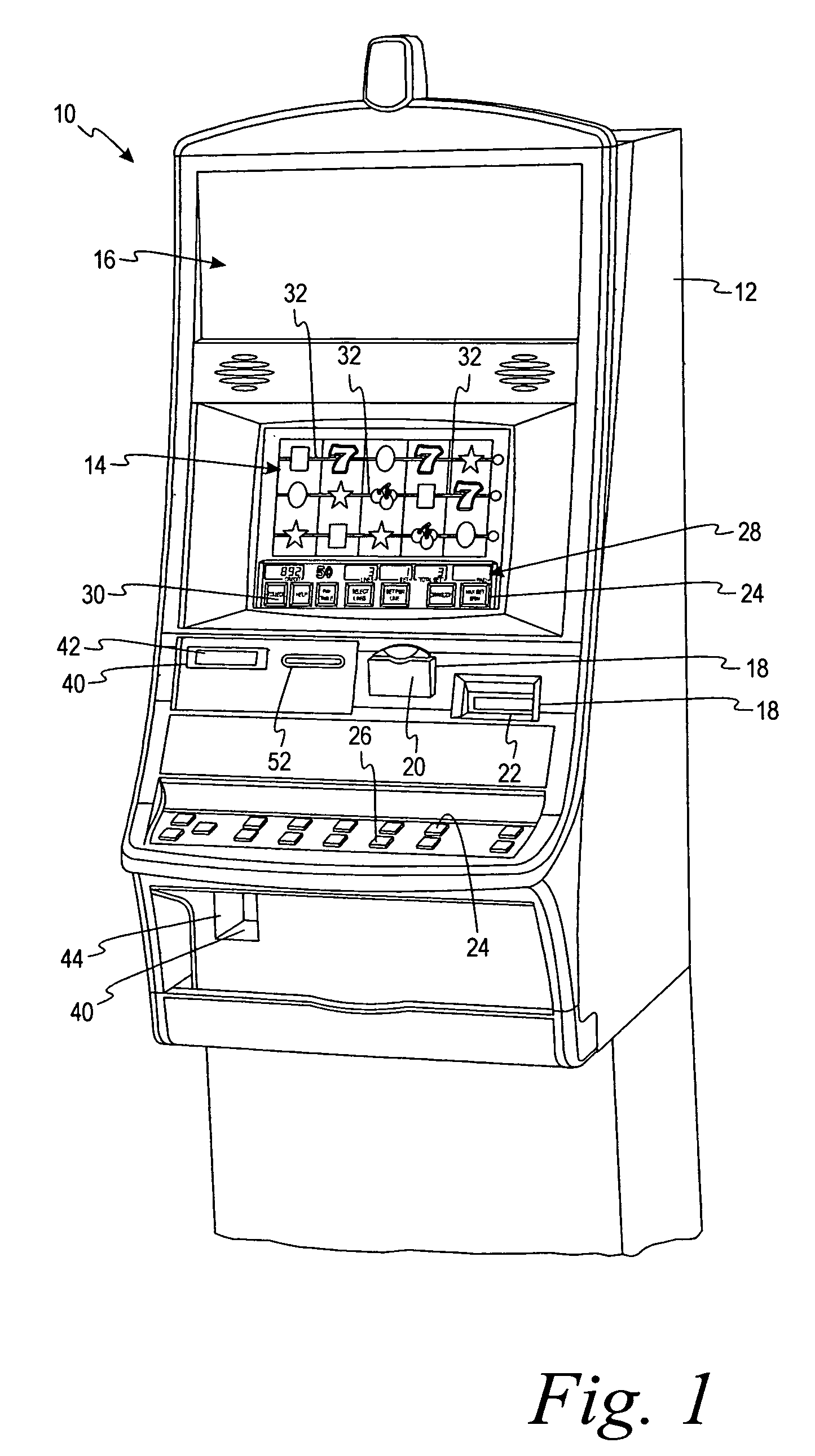

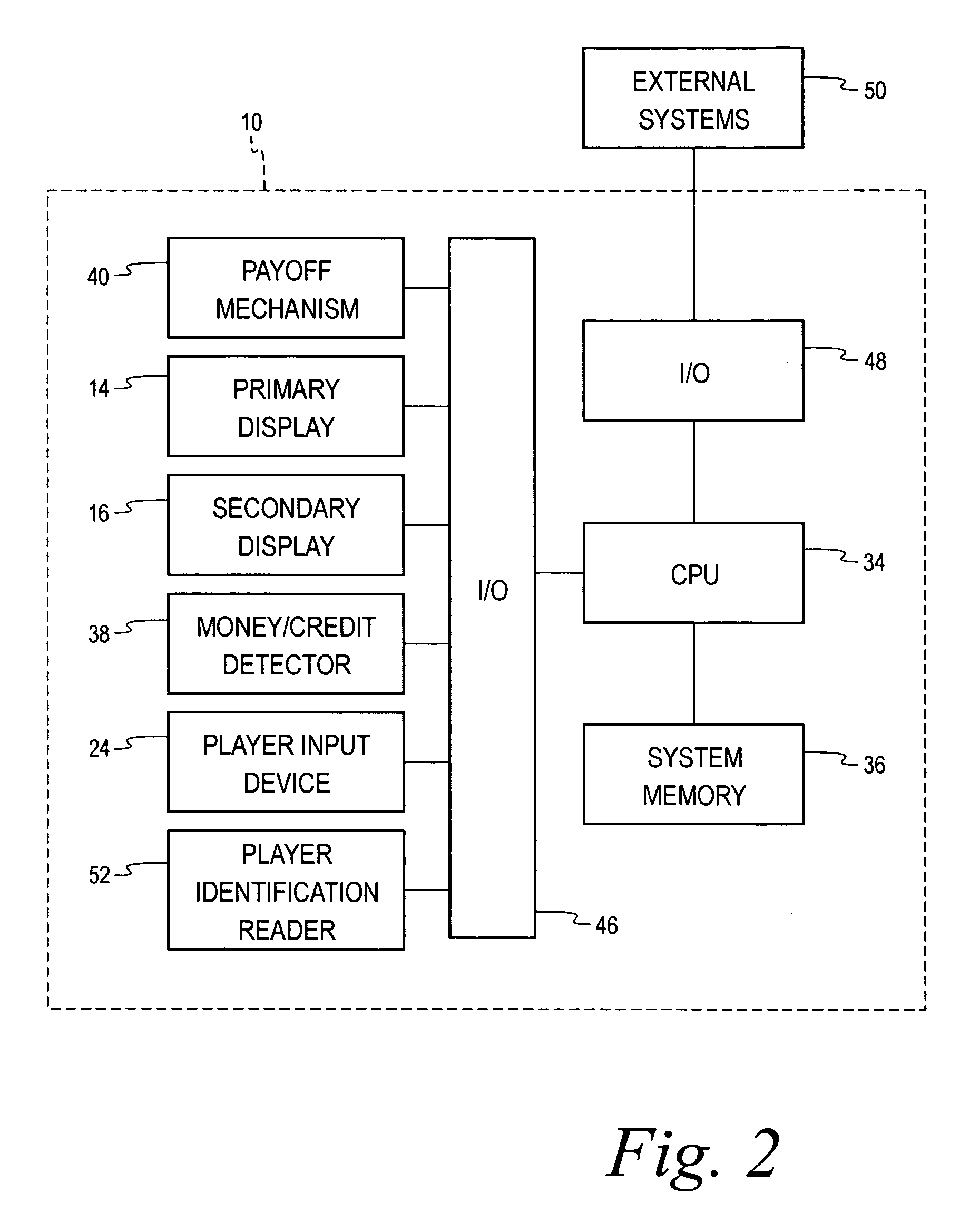

Reel strip attachment

A releasable reel strip attachment assembly including an attachment strip with snap rivets that snaps through corresponding apertures in a reel strip and into apertures in a reel cage. The attachment strip includes an adhesive layer protected by a release backing that is removed to expose the adhesive layer. The reel strip is positioned over the reel cage so that the apertures in the reel strip co-align with those of the reel cage, and the snap rivets are inserted through the aligned apertures to attach the reel strip to the reel cage in a reliable, precise, and consistent manner. The reel strip is wound around the reel cage and the free end of the reel strip is pressed onto the exposed adhesive layer of the attachment strip.

Owner:LNW GAMING INC

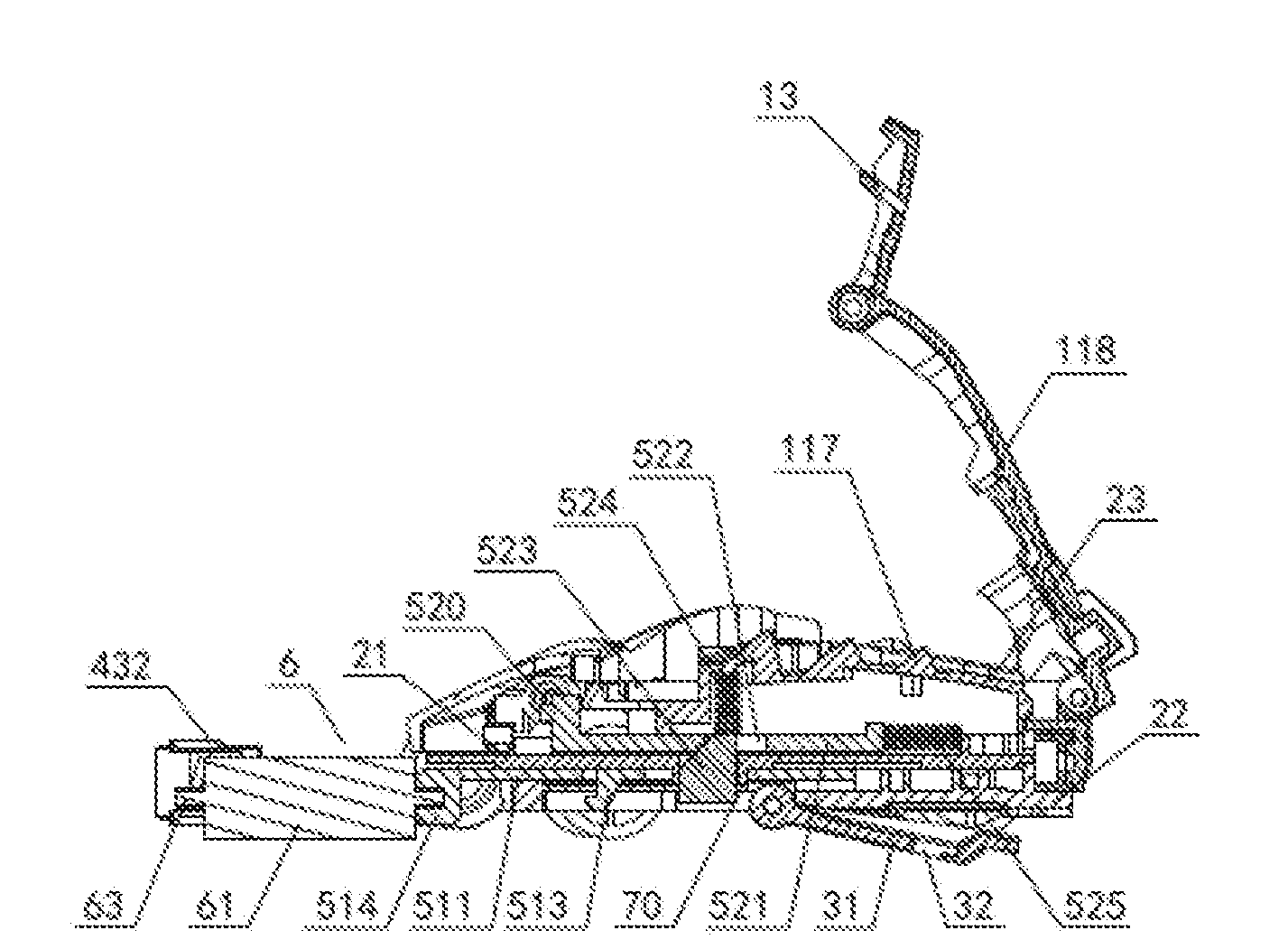

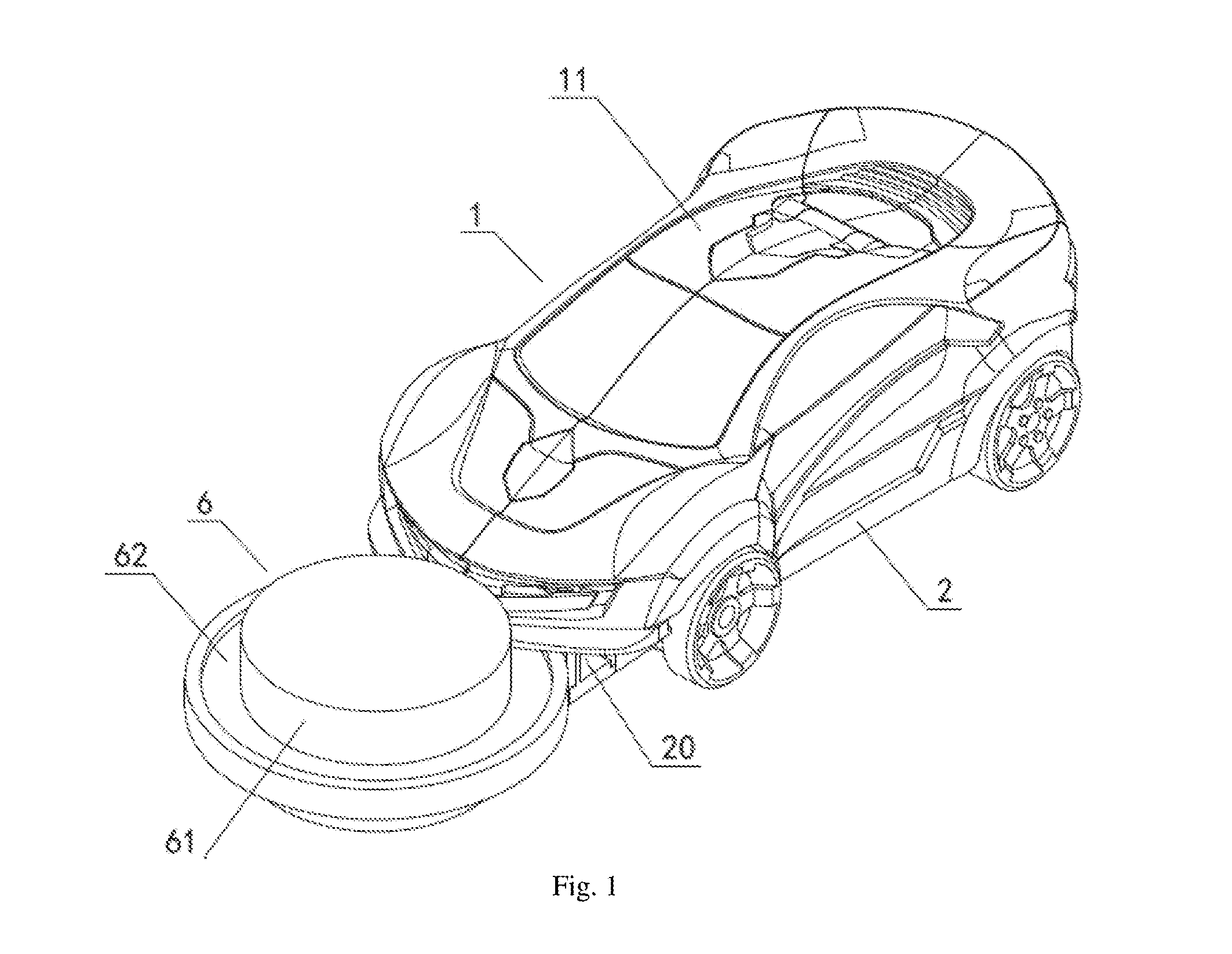

Flipping And Transforming Toy Vehicle Capable Of Gripping Toys

A flipping and transforming toy vehicle capable of gripping toys, comprising a toy vehicle with elastic unfolding parts and flipping parts, toys to be gripped, an elastic gripping part and a snapping assembly. The elastic gripping part, the elastic unfolding parts and the flipping part are folded and snapped through said snapping assembly to maintain the folded state. When the toy vehicle is pushed toward a toy such that the toy touches the snapping assembly, the snap connection of the elastic gripping part, the flipping part and the elastic unfolding parts are released. When the snap connection is release, the elastic gripping part pops out to grip the toy, the flipping part turns downwardly to drive the toy vehicle to somersault, and each elastic unfolding part is unfolded, thereby transforming the toy vehicle from a vehicle form to a second form.

Owner:ALPHA GRP CO LTD +2

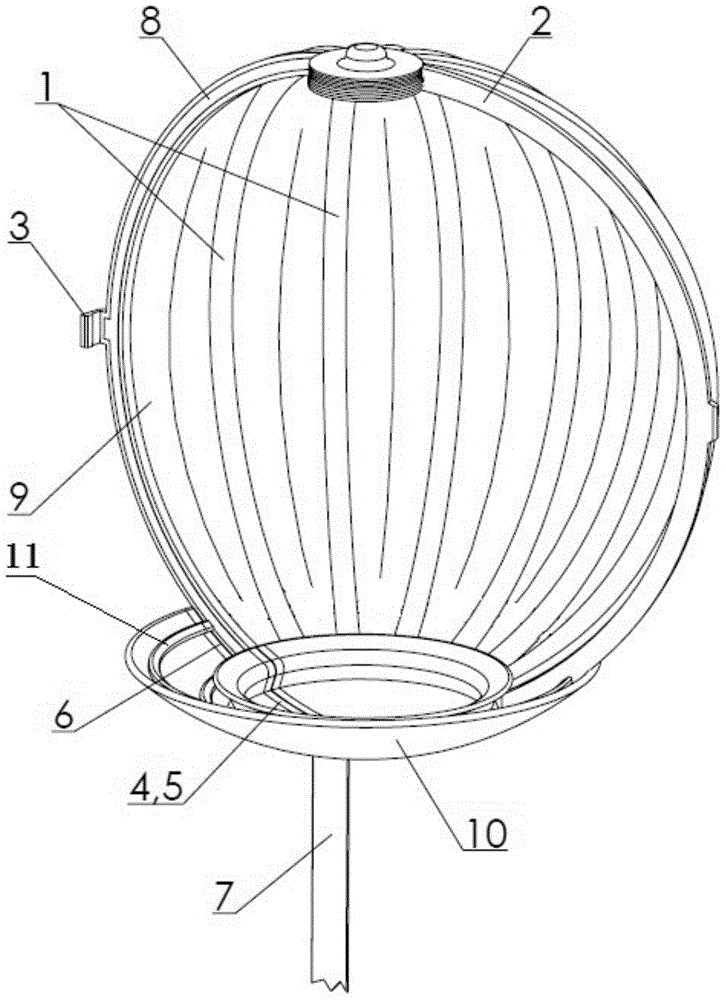

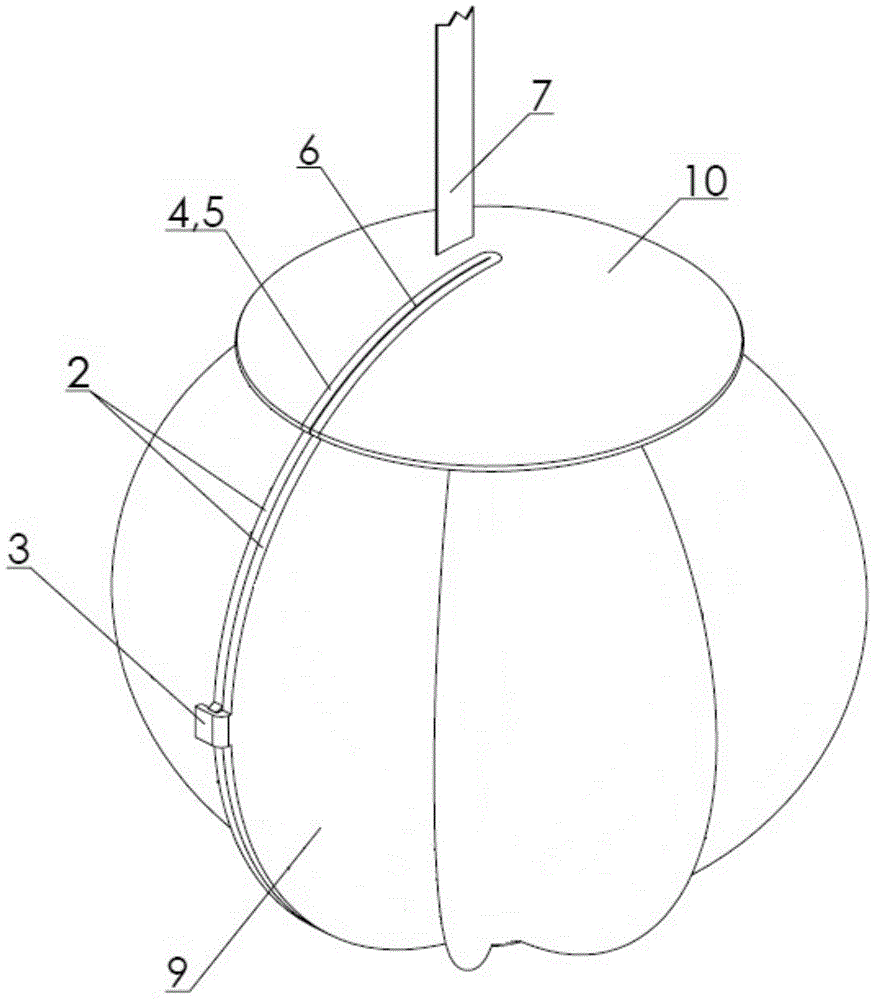

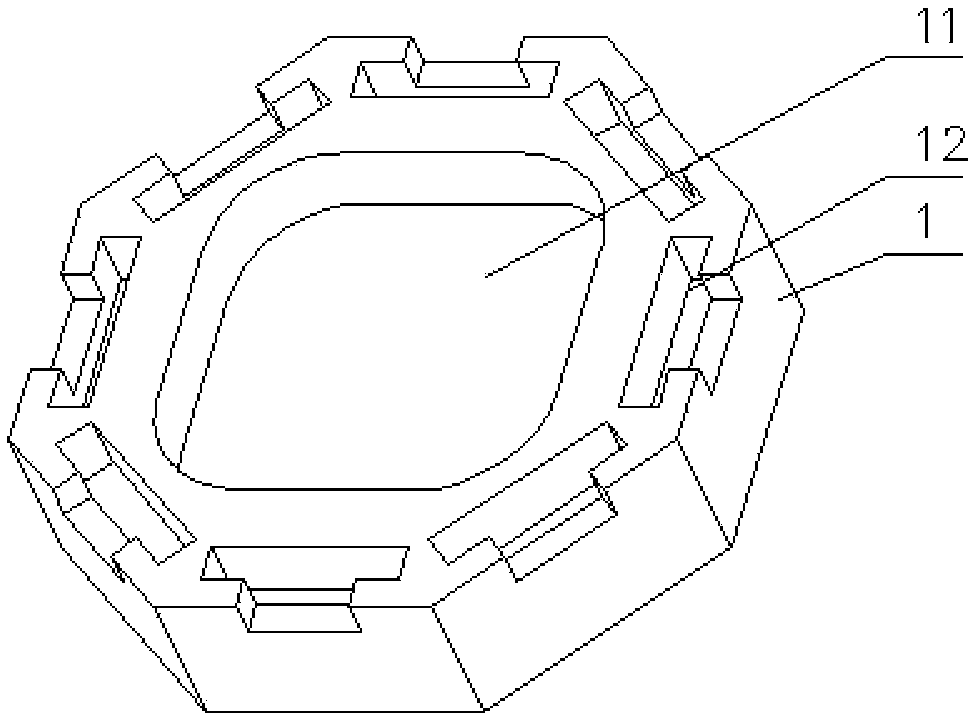

Rotation-folding-type environment-friendly recyclable fruit growth protection device

ActiveCN104996241ACannot be reusedReduce consumptionPlant protective coveringsEnvironmental resistanceMechanical engineering

The invention discloses a rotation-folding-type environment-friendly recyclable fruit growth protection device which is characterized in comprising at least six arc supporting bars, two arc sides and an umbrella-shaped top. An annular slide rail is arranged under the umbrella-shaped top. The upper parts of the arc supporting bars and the arc sides are connected and mated on the annular slide rail. The lower parts of the arc supporting bars and the arc sides are hinged together. The slidable arc sides can be closed and can be snapped through snap buckles. Rubber sealing strips are provided on the contact surfaces of the two arc sides. The arc supporting bars are distributed with equal spaces along the annular slide rail. A foldable film connected with the arc supporting bars and the arc sides is arranged around the arc supporting bars and the arc sides, and covers the arc supporting bars and the arc sides, such that a spherical cavity is formed. A fruit stalk gap is arranged on the edge of the umbrella-shaped top. The assembly process of the device is simple and fast. The device is not prone to deformation and damage, and can be recycled repeatedly. Therefore, an average cost is reduced, and energy consumption is reduced. The device has better environment friendliness.

Owner:重庆市麦腾农业开发有限公司

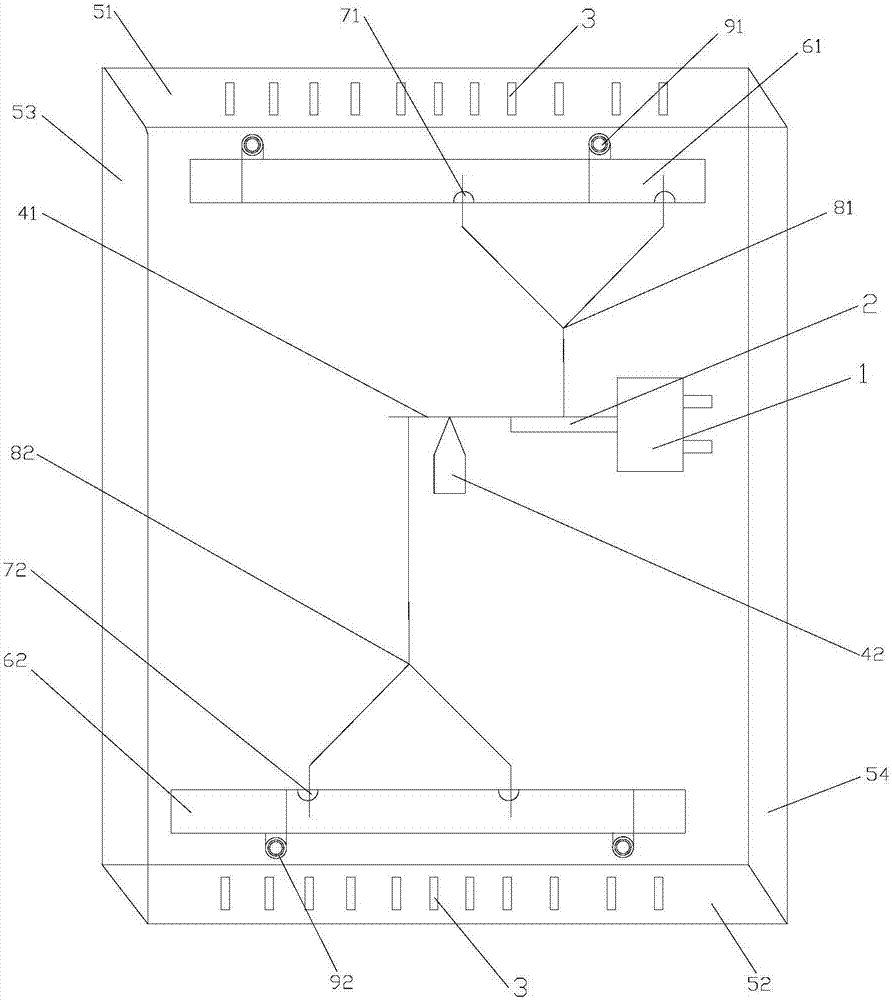

Automatic fire extinguishing system for liquid crystal display television

ActiveCN106902485ASimple structureMature and reliable technologyTelevision system detailsFire rescueTelevision equipmentEngineering

The invention relates to the field of liquid crystal display television equipment, in particular to an automatic fire extinguishing system for a liquid crystal display television. The automatic fire extinguishing system comprises a television shell, a liquid crystal screen module and a circuit module. The television shell and the liquid crystal screen module are connected in a matched manner. The circuit module is arranged in a space formed by the television shell and the liquid crystal screen module. Vent holes are formed in the television shell. A snap-through type double-metal-sheet temperature controller, a baffle, a connecting rod, a torsion spring, a limiting and buckling mechanism and a hopping connecting rod are arranged in the space formed by the television shell and the liquid crystal screen module. The snap-through type double-metal-sheet temperature controller is driven by the hopping connecting rod and the connecting rod, the limiting and buckling mechanism loses the limit to the baffle, and the vent holes can be covered with the baffle under the effect of the torsion spring. The automatic fire extinguishing system for the liquid crystal display television is simple in structure and high in safety.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Two-way type fastener for abutting joint of connecting plates

The invention discloses a two-way type fastener for abutting joint of connecting plates. The two-way type fastener comprises an abutting joint piece; each side of the abutting joint piece is provided with a connecting piece; each connecting piece is provided with a snapping piece which is connected with an extension piece; each connecting piece is provided with an external unfolding piece; the abutting joint piece is in insertion joint with a fixing pin; one end of the fixing pin is provided with a snapping cap; the other end of the fixing pin is provided with a nut. According to the two-way type fastener for the abutting joint of the connecting plates, connecting plate bodies can be arranged on the bilateral sides of the abutting joint pieces respectively, each connecting plate body is snapped through the corresponding snapping piece and the corresponding connecting piece, and accordingly the abutting joint on the connecting plate bodies can be performed conveniently.

Owner:赵静

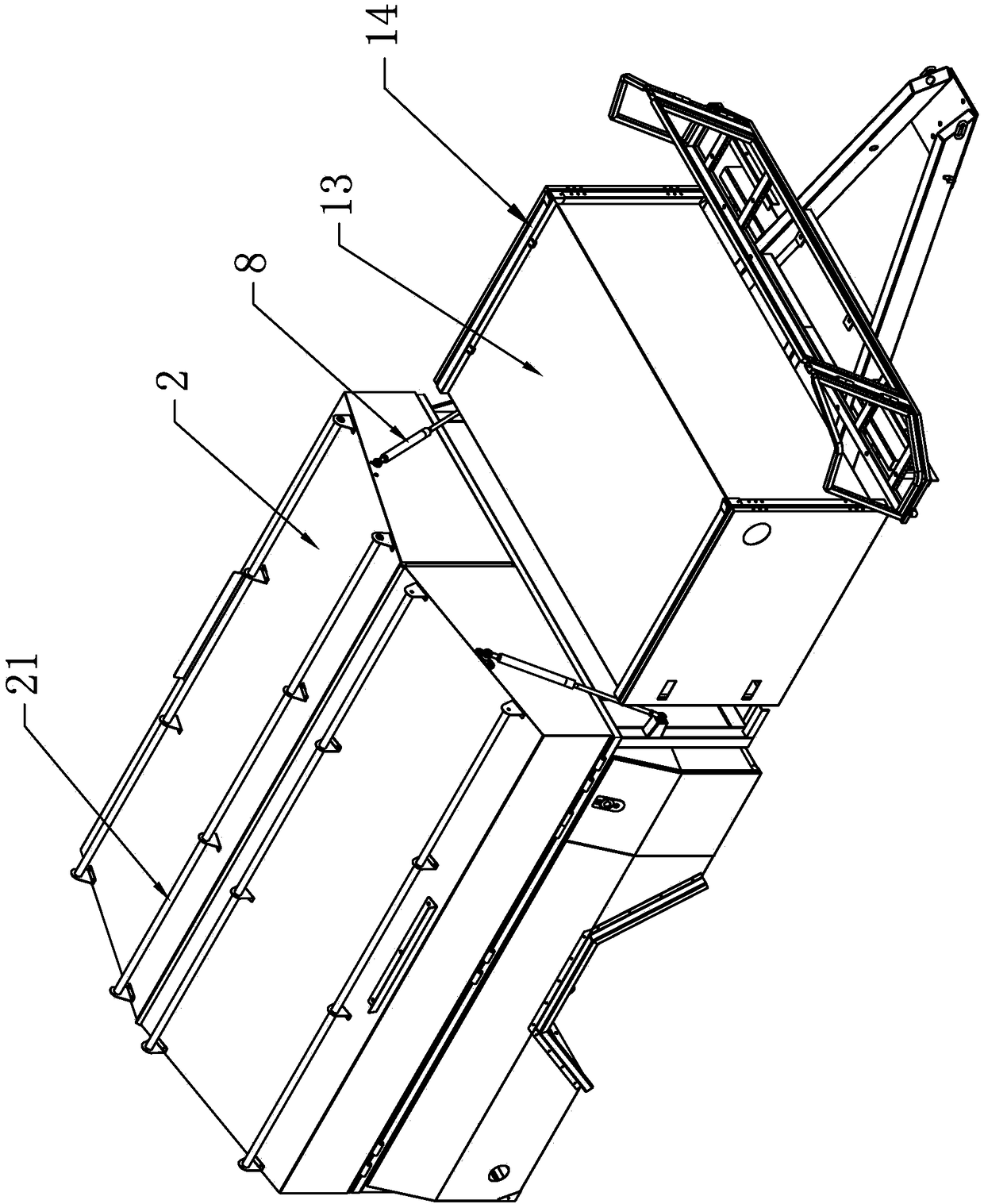

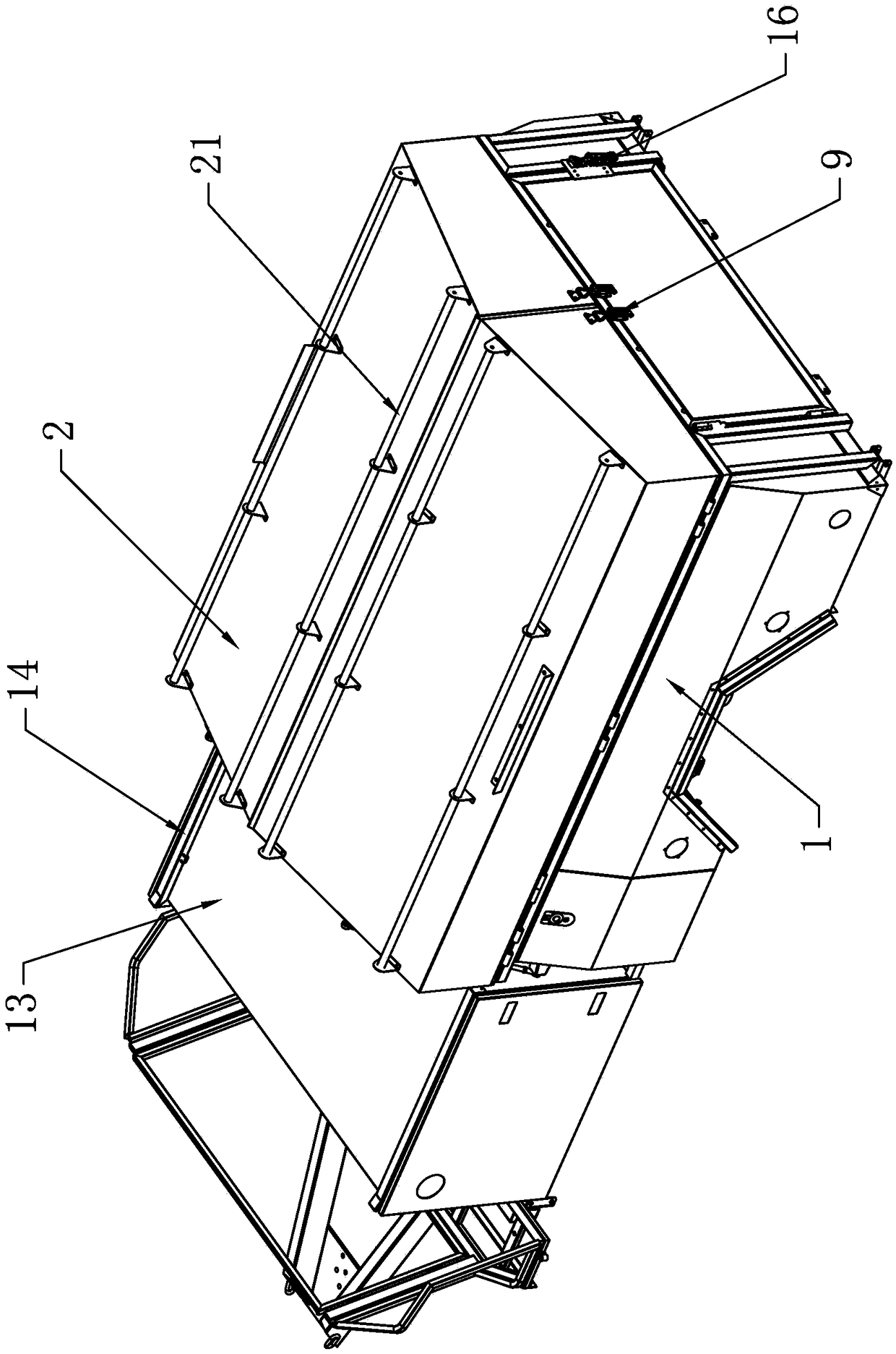

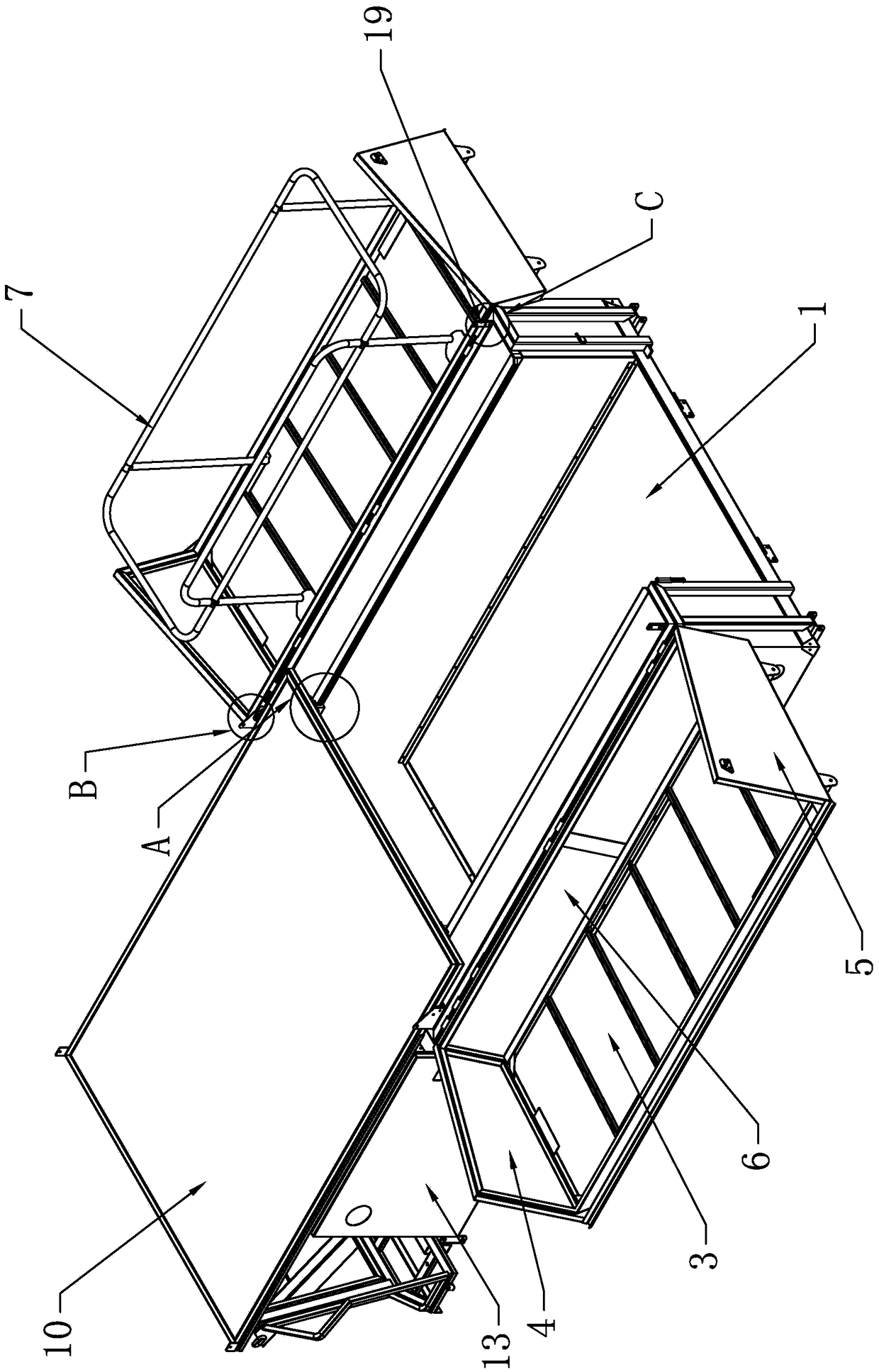

A double-turn saloon car

InactiveCN109109728AEasy to assembleEasy to installVehicle with living accommodationEngineeringMechanical engineering

The invention provides a left-right double-turn saloon car. The left-right double-turn saloon car includes a vehicle body, the vehicle body comprises a carriage with an open top, the top opening of the compartment is snapped through the left and right roof covers, each top cover is enclosed by a top plate, a front plate, a rear plate and side plates, and the side edges of the two side plates enclosed by the two top covers are respectively hinged with the left and right sides of the top opening of the compartment, a frame bed is respectively arranged in the inner cavity of each top cover, and after the top cover is opened and fastened, each front plate and each rear plate are respectively fixedly connected with the side wall of the compartment. The left and right double-overturned saloon car can provide a plurality of beds for rest, fully utilizes the saloon car space, and meets the needs of people. The push-pull bed plate can be firmly connected with the carriage, and the top cover canbe firmly connected with the carriage when the top cover is opened and engaged. The top plate of the top cover is inclined so as to be convenient to support and bear force.

Owner:荣成康派斯新能源车辆股份有限公司

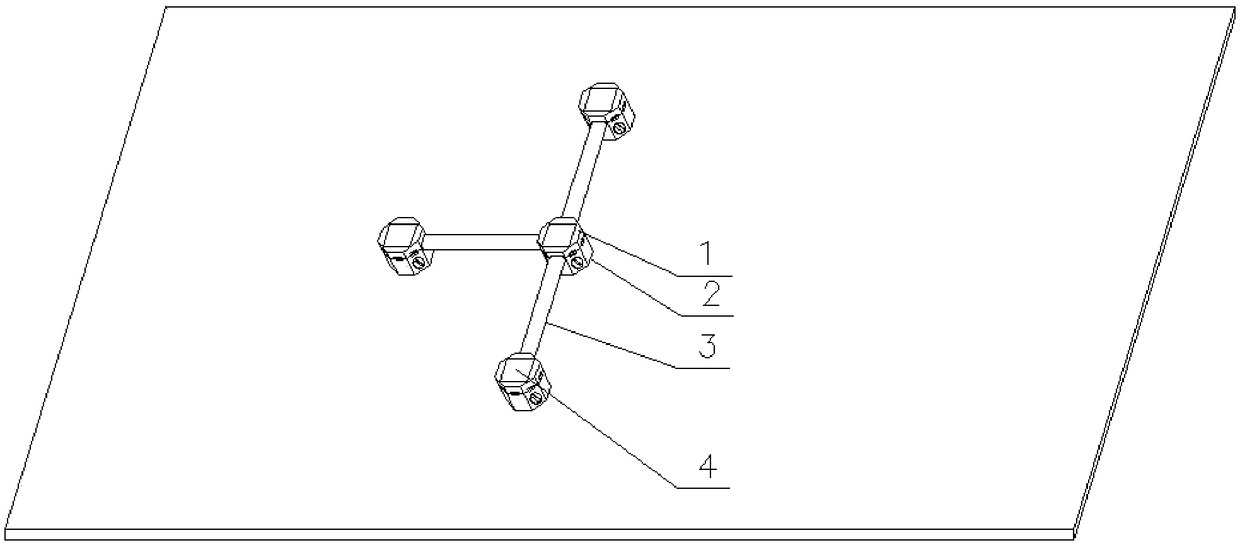

Mind mapping tool for economic management

InactiveCN108735046AEasy to manufactureEasy to displayTeaching apparatusEconomic managementIdentification plate

The invention discloses a mind mapping tool for economic management. The mind mapping tool comprises a displaying board, a plurality of expansion piles and a plurality of connectors. The expansion piles are detachably connected with the upper surface of the displaying board. Two random expansion piles are detachably connected by means of a connector. The expansion pile comprises a seat which is detachably connected with the displaying board. A top plate is arranged above a seat. The top plate is detachably connected with the seat in a snapping manner. The top surface of the top plate is provided with an identification plate. The identification plate is fixed to the top plate. According to the mind mapping tool, the two random expansion piles can be snapped through the connector according to the actual requirement, thereby expanding to multiple overlapping shapes, and facilitating manufacturing and displaying in mind mapping. The mind mapping tool has advantages of convenient operation,high flexibility, high practicability and high popularization value.

Owner:ZHENGZHOU UNIV OF IND TECH +1

Device based on traditional Chinese medicine dreg filtering structure

InactiveCN107823942AEasy to carryEasy to transport in large quantitiesSeparation devicesMembrane filtersEngineeringStructure based

A device based on a traditional Chinese medicine dreg filtering structure solves the problem that an existing traditional Chinese medicine filter cannot be folded, is not easy to carry and cannot realize replacement of a filter net. The device is characterized in that a first handle is arranged at the middle of the left end of a first frame, a second handle is arranged at the middle of the right end of a second frame, and the first frame and the second frame are connected through a rotating shaft and are matched with each other. Four edges of each of the first frame and the second frame are separately provided with snap fasteners. A filter net is put on the top of each of the first frame and the second frame, and the two filter nets are separately connected with the first frame and the second frame through the snap fasteners. According to the device, the first frame and the second frame are unfolded just through the rotating shaft, a first handle or a second handle is held by a hand, and medicinal dregs can be filtered through the two filter nets. The first frame and the second frame are folded only by the rotating shaft to realize the purpose of convenient carrying. The filter nets to be replaced can be replaced only by opening the snap fasteners, and a new filter net can be installed on the first frame or the second frame via the snap fasteners.

Owner:MIANYANG ANZHI SHENGDA CREATIVE TECH

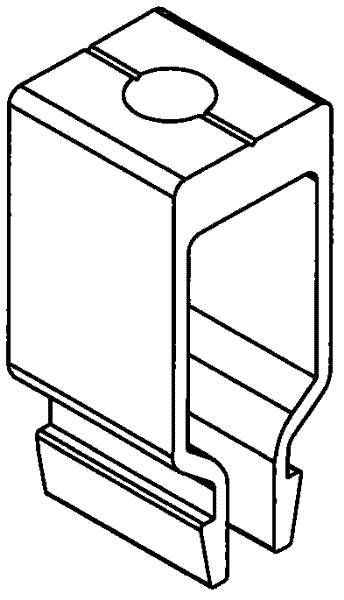

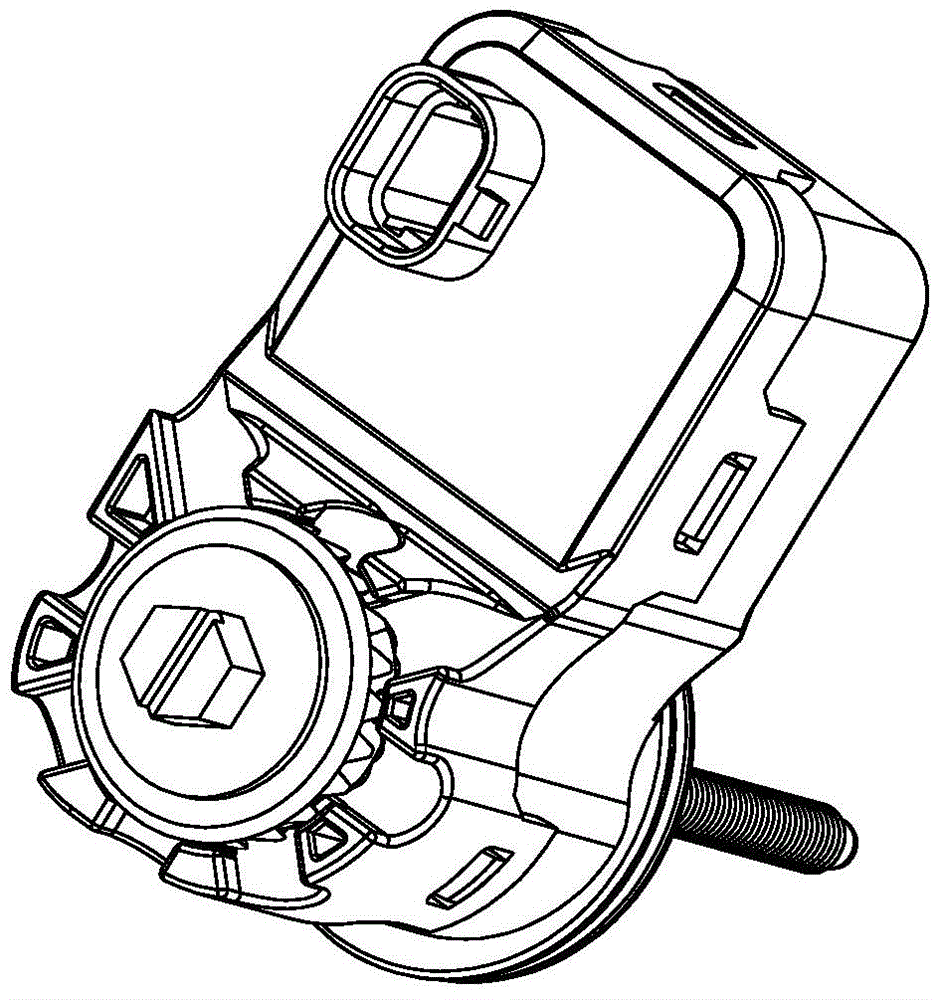

Automotive light dimming motor

ActiveCN104901465AImprove stabilityImprove sealingSupports/enclosures/casingsElectrical and Electronics engineeringSnap through

The invention discloses an automotive light dimming motor which comprises an upper housing and a lower housing. The upper housing is provided with a jack for placing a pin. The lower housing is internally provided with a motor and a circuit board. The pin is connected with the jack through injection molding. The side surface of the circuit board is provided with an elastic socket which is used for connecting with the tail end of the pin. The tail end of the pin is inserted into the elastic socket. The circuit board is parallel with the inside surface of the lower housing. The inside surface of the lower housing is also provided with a snapping base for snapping the circuit board. The snapping base is provided with a snapping trough for placing one side of the circuit board. The inner bottom surface of the lower housing is also provided with a block which is used for abutting against one side of the circuit board. According to the structure, because the pin is connected with the jack through injection molding, no slit exists between the pin and the jack, thereby realizing a relatively good sealing performance and no easy shake of the pin. Furthermore the circuit board is snapped through the snapping base, and the circuit board is fixed through the block, thereby preventing shake of the circuit board, realizing no easy shake of the circuit board and the pin, and obtaining relatively high stability.

Owner:NINGBO JINGHUA ELECTRONICS TECH

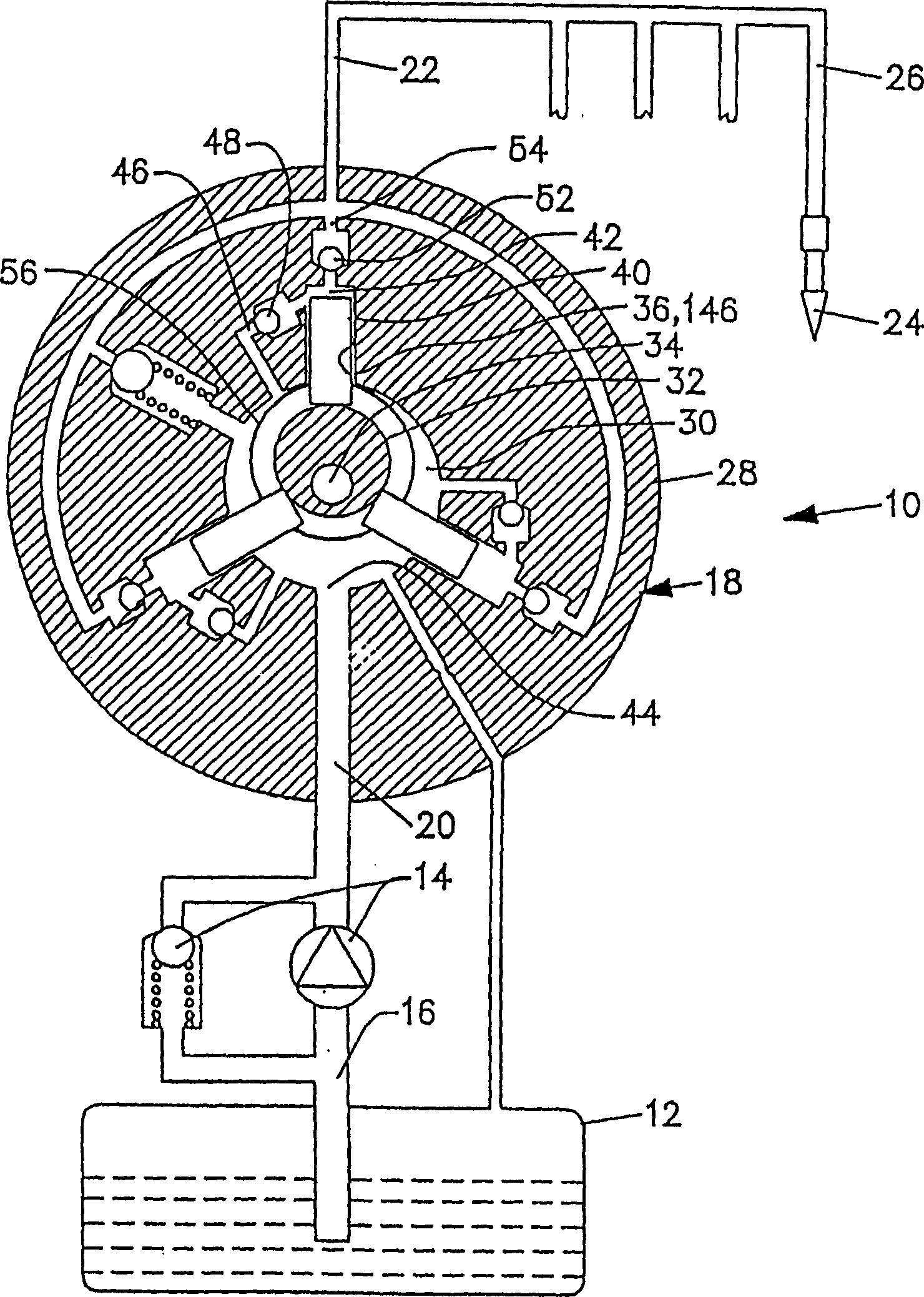

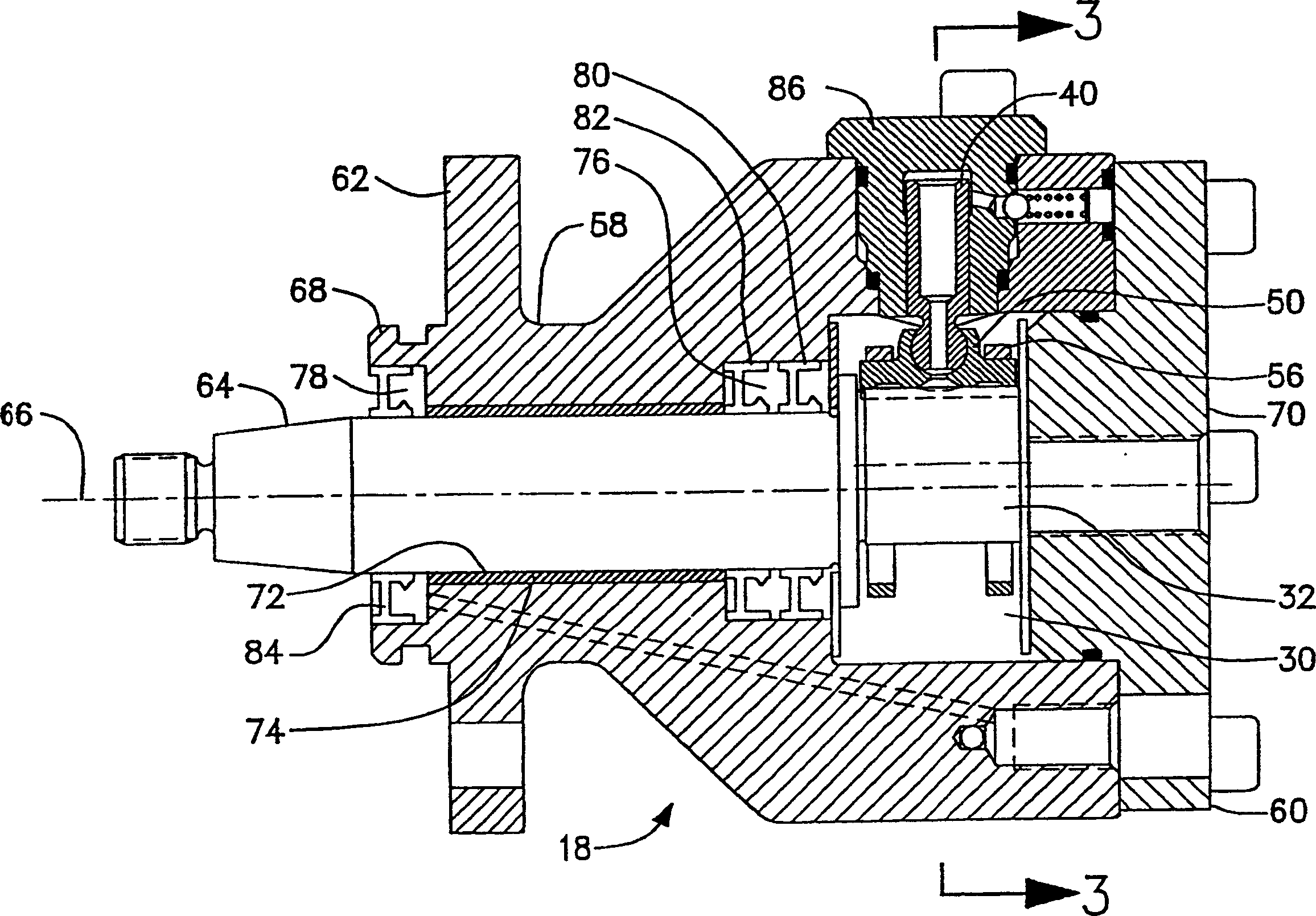

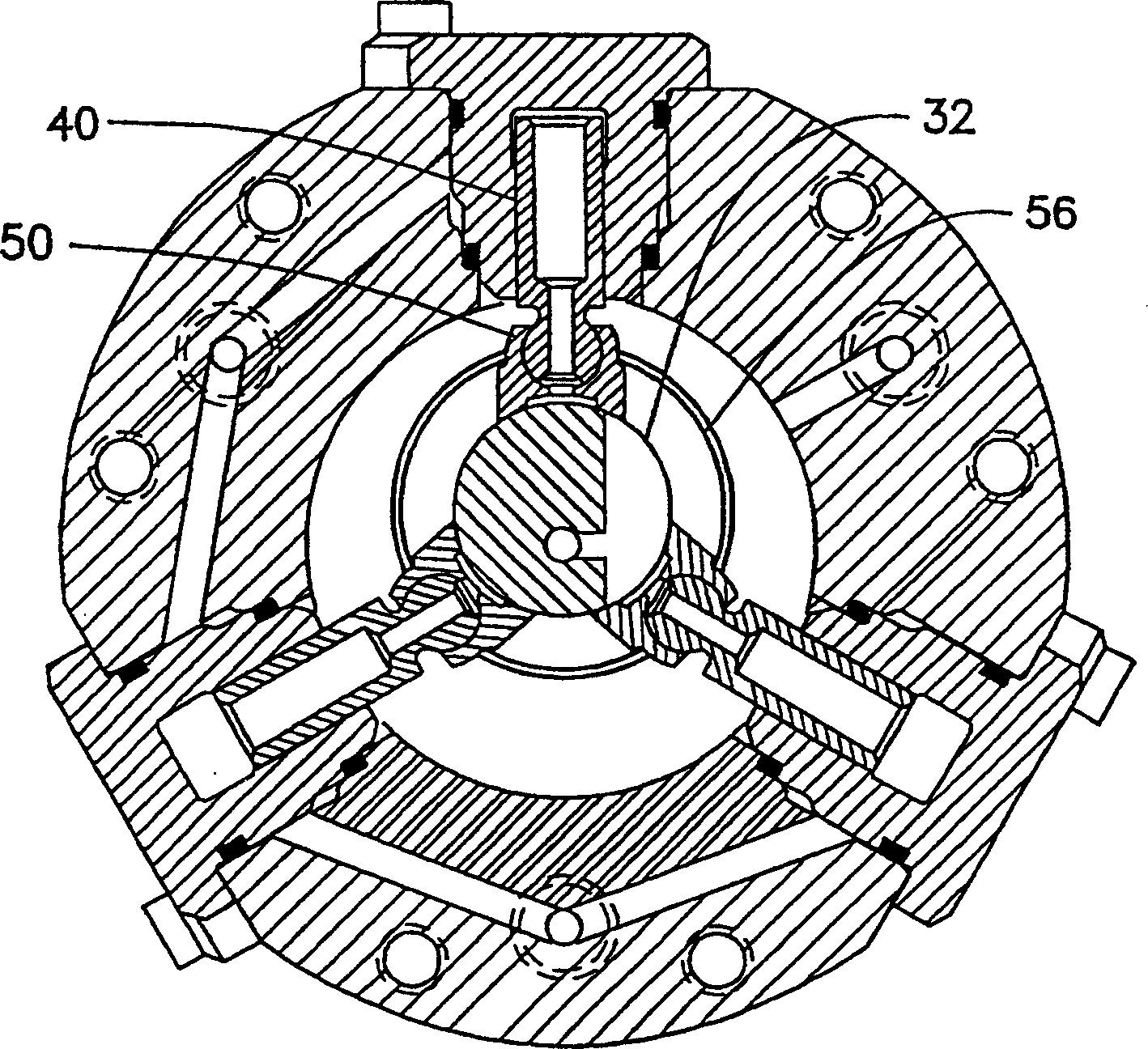

Snap-in connection for pumping plunger sliding shoes

A fuel supply pump having a plurality of radially disposed plunger sleeves each containing a pumping plunger with a driven end reciprocally movable within the plunger sleeve between a pumping position and a filling position. The fuel supply pump includes a rotatable drive member and a plurality of sliding shoes. Each shoe has a first face adjacent a respective plunger driven end and a second face adjacent the drive member. In one variation, each shoe first face includes a socket which the plunger driven end snaps into and is captured by, creating a sliding shoe assembly. A case couples all of the sliding shoe assemblies. In another variation, the cage includes apertures which the plunger driven end snaps through, thereby capturing the plunger. The plunger driven end engages a seat included on the sliding shoe first face. Rotation of the drive member moves each shoe, and thereby, each plunger toward the pumping position. As one plunger is actuated toward the pumping position by the eccentric member at least one plunger is retracted to the filling position by the coupling of the cage. The coupling of the shoe assemblies and the cage allows for the creation of a controlled gap between the shoes second face and the drive member for part of the drive member rotation. Also a method of fuel supply pump assembly using sub-assemblies which can be assembled externally to the fuel supply pump body.

Owner:STANADYNE AUTOMOTIVE

Hinge coupling

Disclosed is a hinge coupling comprising a first connective section comprising a hollow first cylinder at one end with a first piece fastened therein, two parallel projections at the other end, each projection having a bent end, a bore in an intermediate portion open to the external, and a bar interconnected the bent ends, the bar being not aligned with rest of the first connective section, and a second connective section comprising an extension at one end, a hollow second cylinder substantially passed from one end to the other end, an intermediate recess, and a groove formed at bottom of the recess. The bar is fastened in the groove by snapping through the recess, a second piece is inserted into the second cylinder by passing over the bar, and the extension is inserted into the bore by counterclockwise pivoting about the bar. Both sections are parallel after folding.

Owner:YOU CHING CHUAN

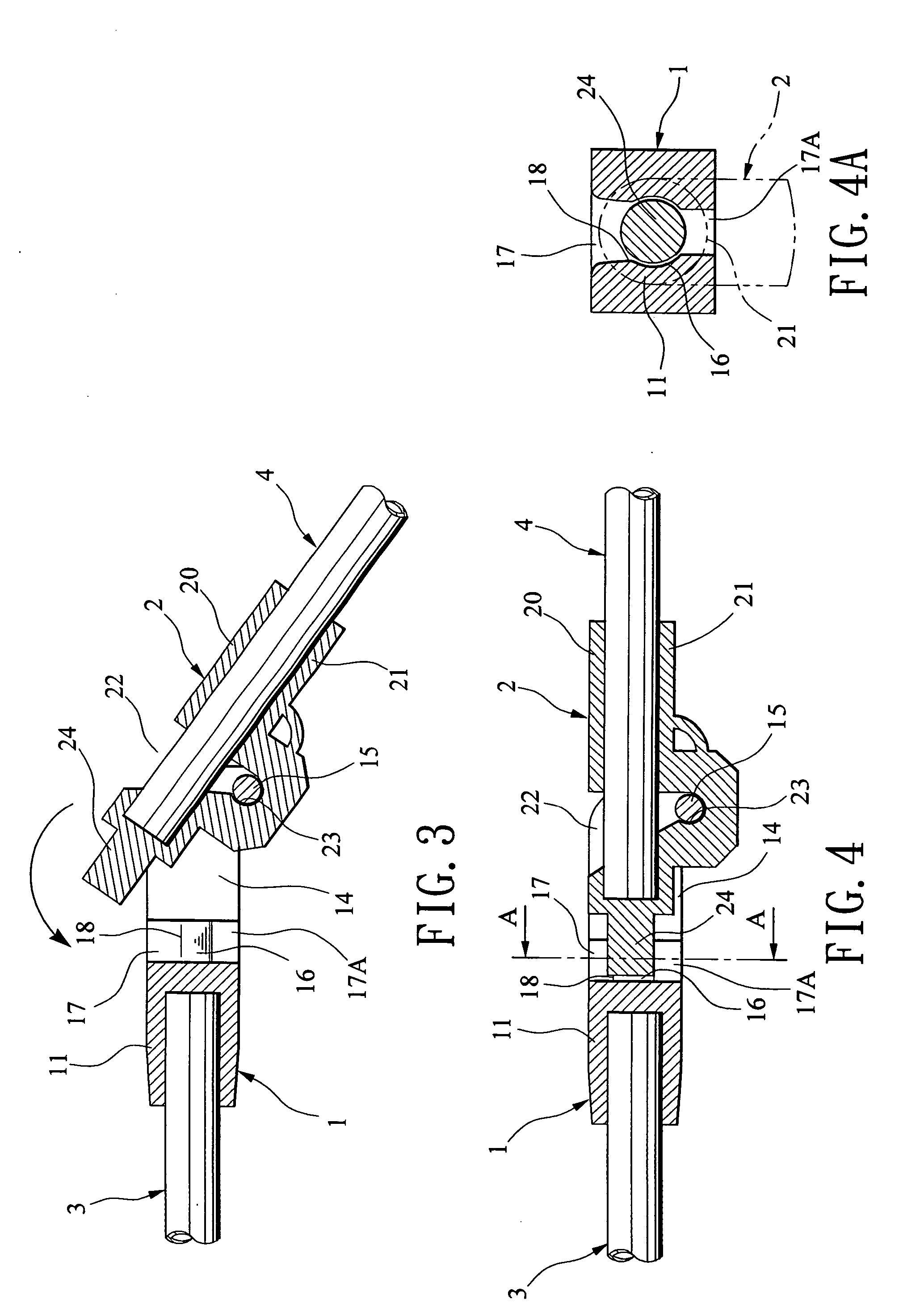

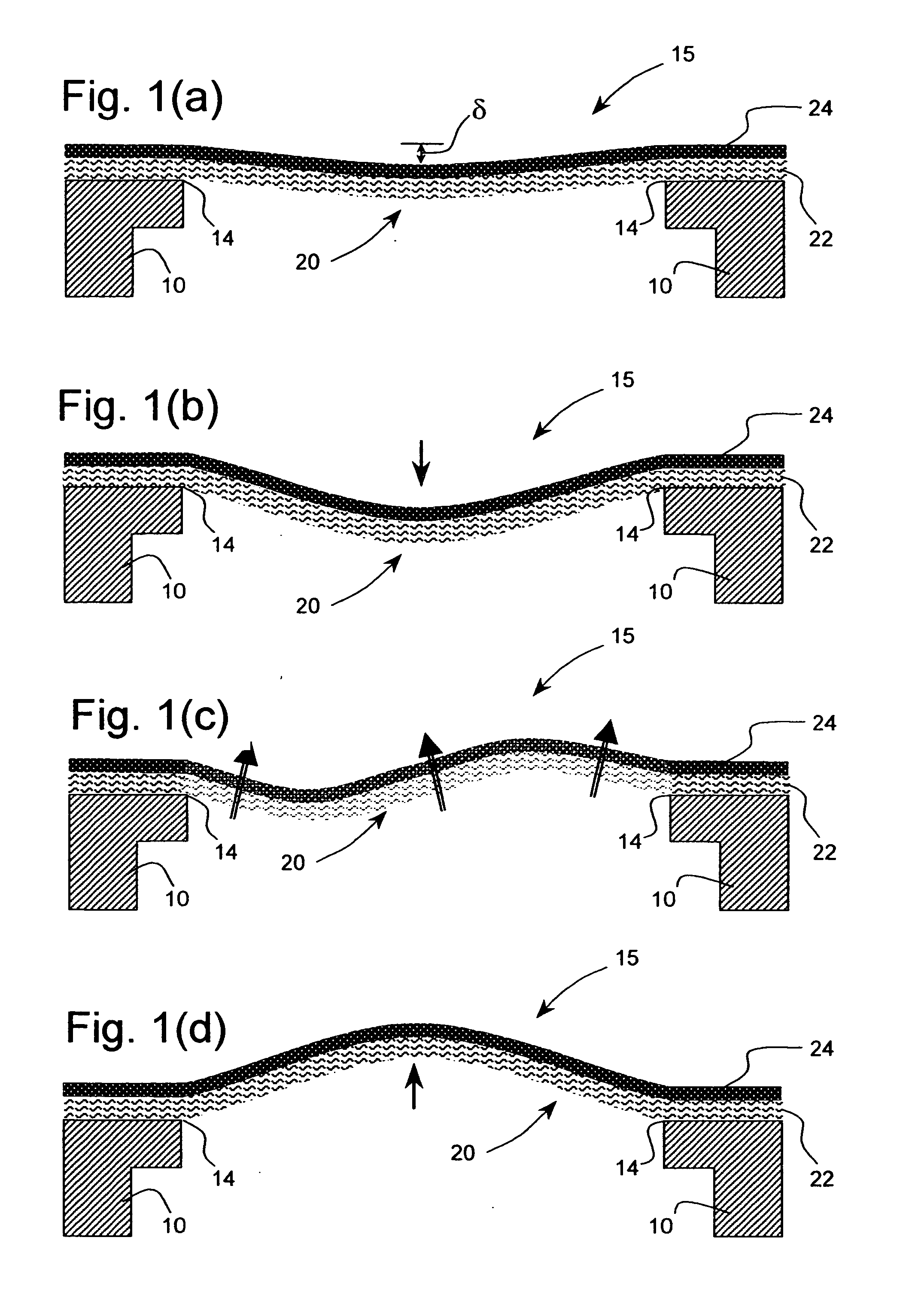

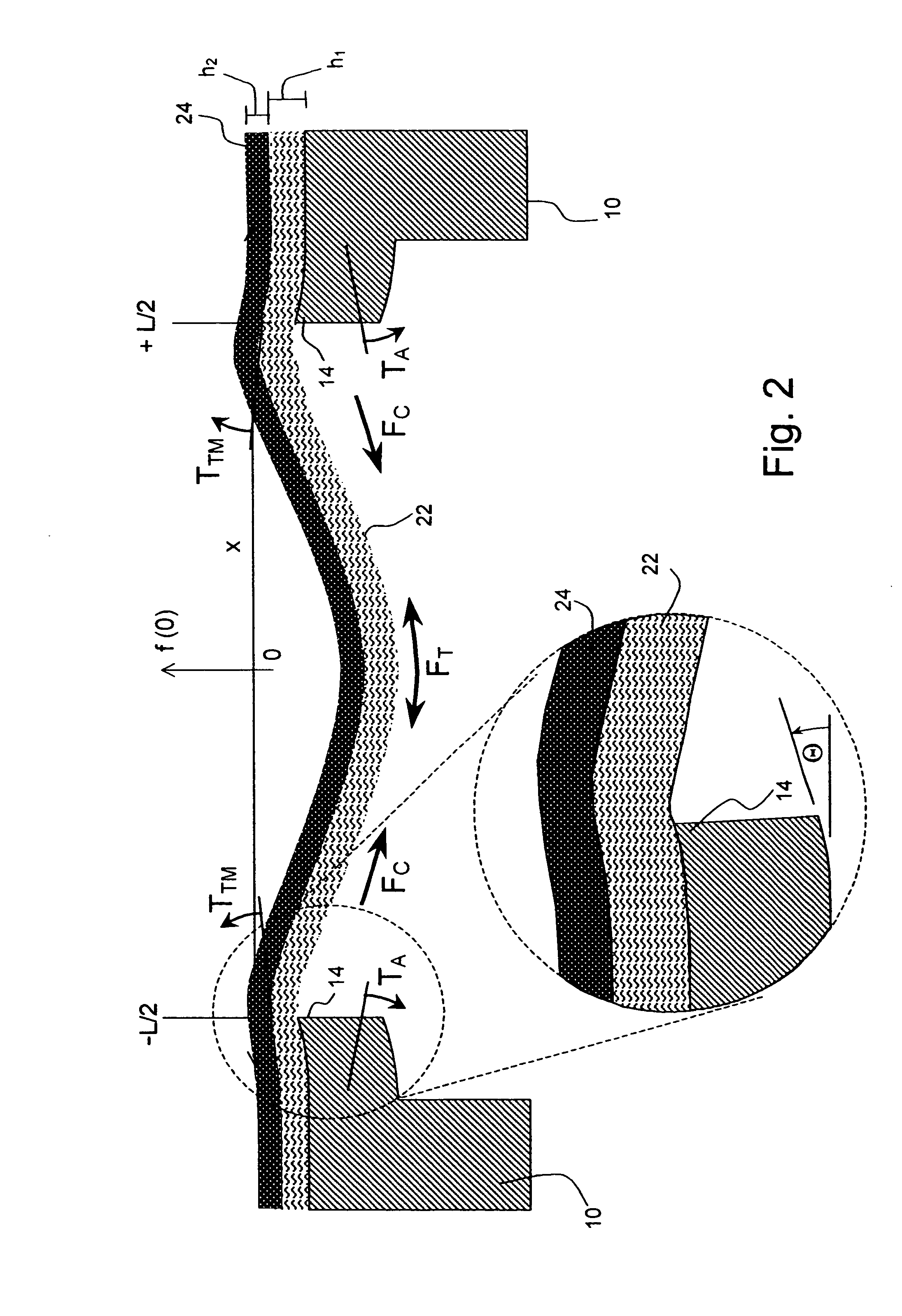

Snap-through thermal actuator

InactiveUS20050099463A1Large force magnitude and accelerationPrintingThermal electric motorFluid controlLight energy

A snap-through thermal actuator for a micro-electromechanical device such as a liquid drop emitter or a fluid control microvalve is disclosed. The snap-through actuator is comprised of a base element formed with a depression having opposing anchor edges which define a central plane. A deformable element, attached to the base element at the opposing anchor edges, is constructed as a planar lamination including a first layer of a first material having a low coefficient of thermal expansion and a second layer of a second material having a high coefficient of thermal expansion. The deformable element is formed to have a residual shape bowing outward from the central plane in a first direction away from the second layer. The snap-through thermal actuator further comprises apparatus adapted to apply a heat pulse to the deformable element which causes a sudden rise in the temperature of the deformable element. The deformable element initially bows farther outward in the first direction, then, due to thermomechanical torque's acting at the opposing anchor edges, reverses and snaps through the central plane to bow outward in a second direction toward the second layer, and then relaxes to the residual shape as the temperature decreases. The snap-through thermal actuator is configured with a liquid chamber having a nozzle, a fluid flow port to form a liquid drop emitter or a fluid control microvalve, or to activate an electrical microswitch. Heat pulses are applied to the deformable element by resistive heating or by light energy pulses.

Owner:EASTMAN KODAK CO

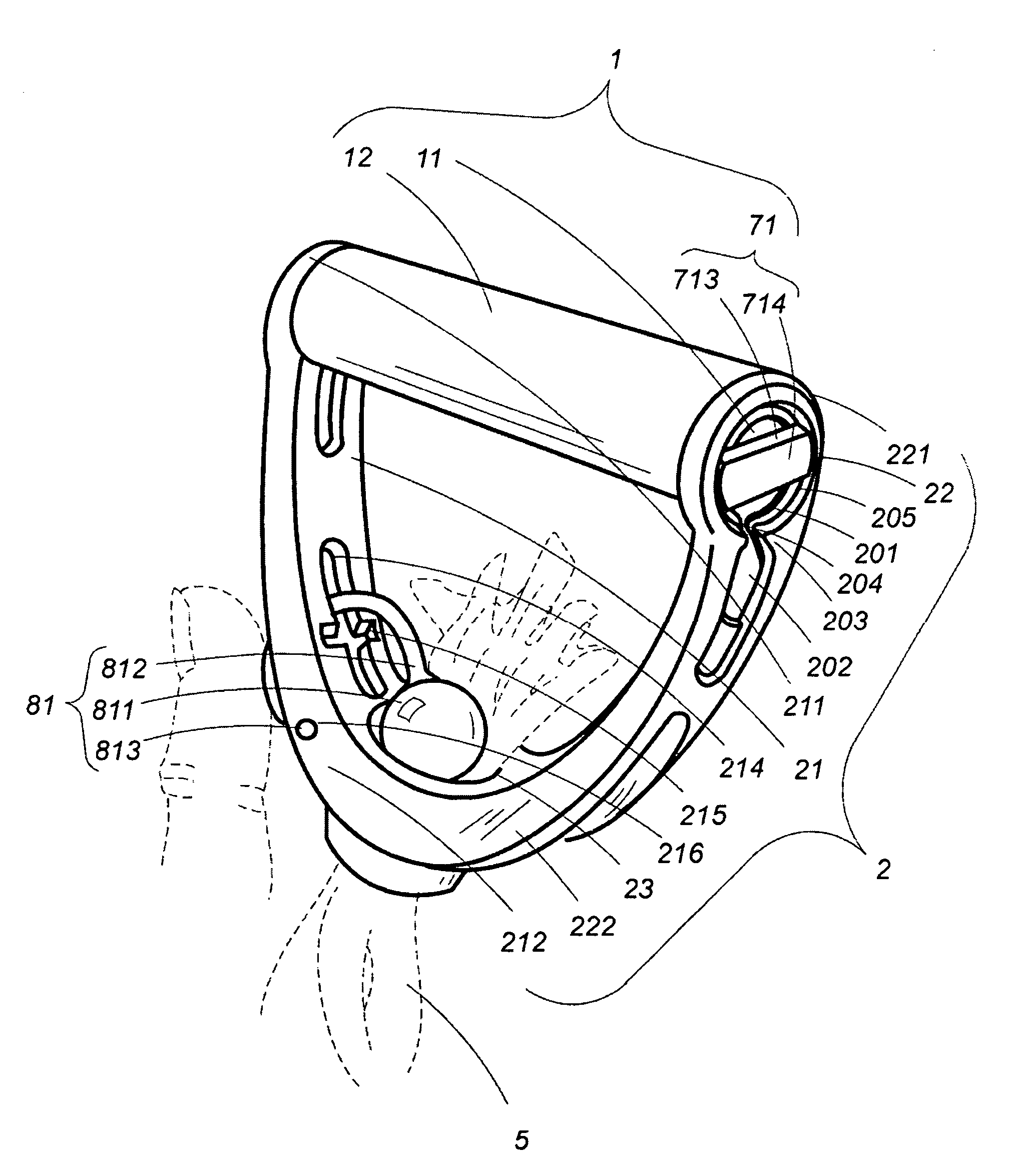

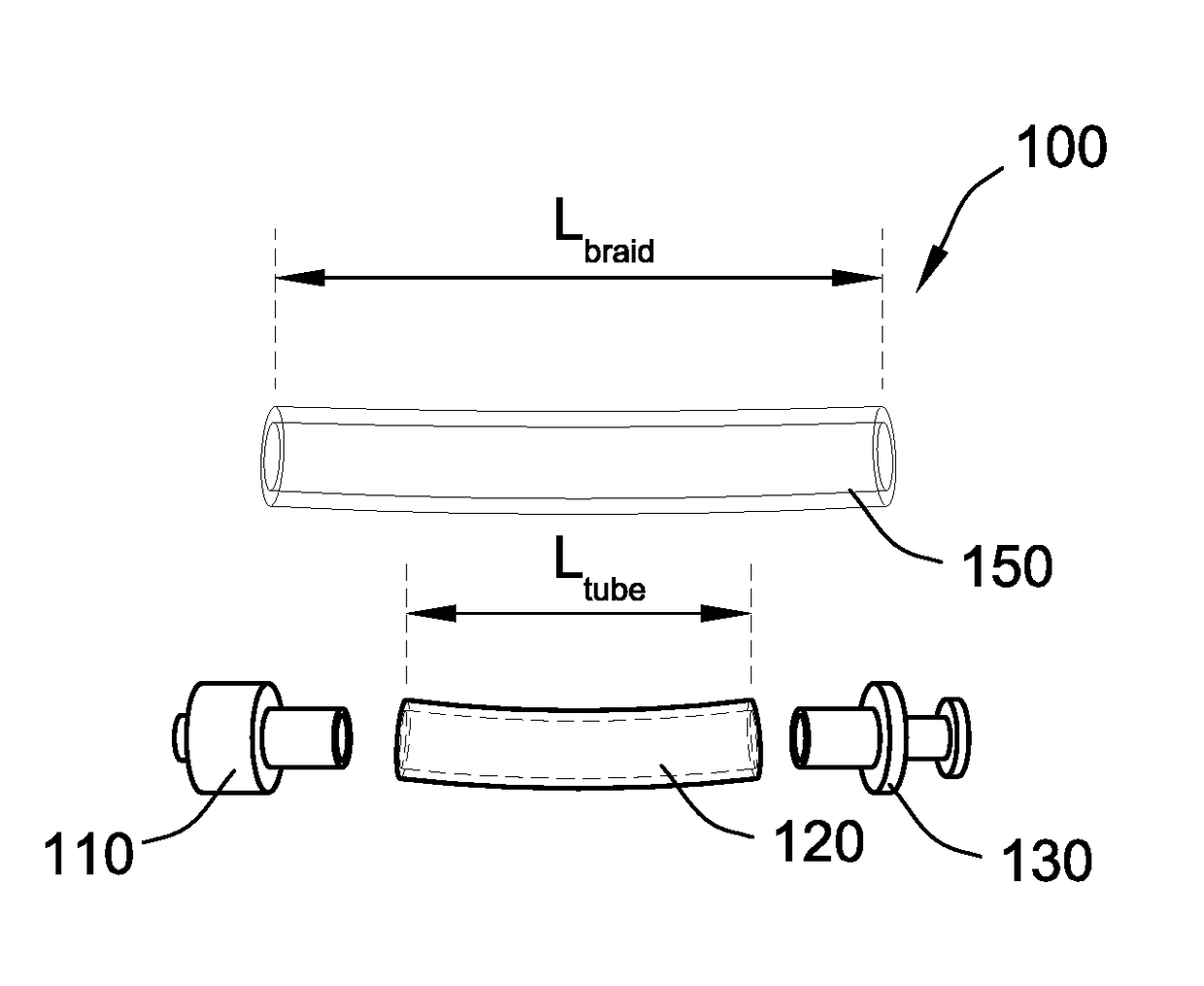

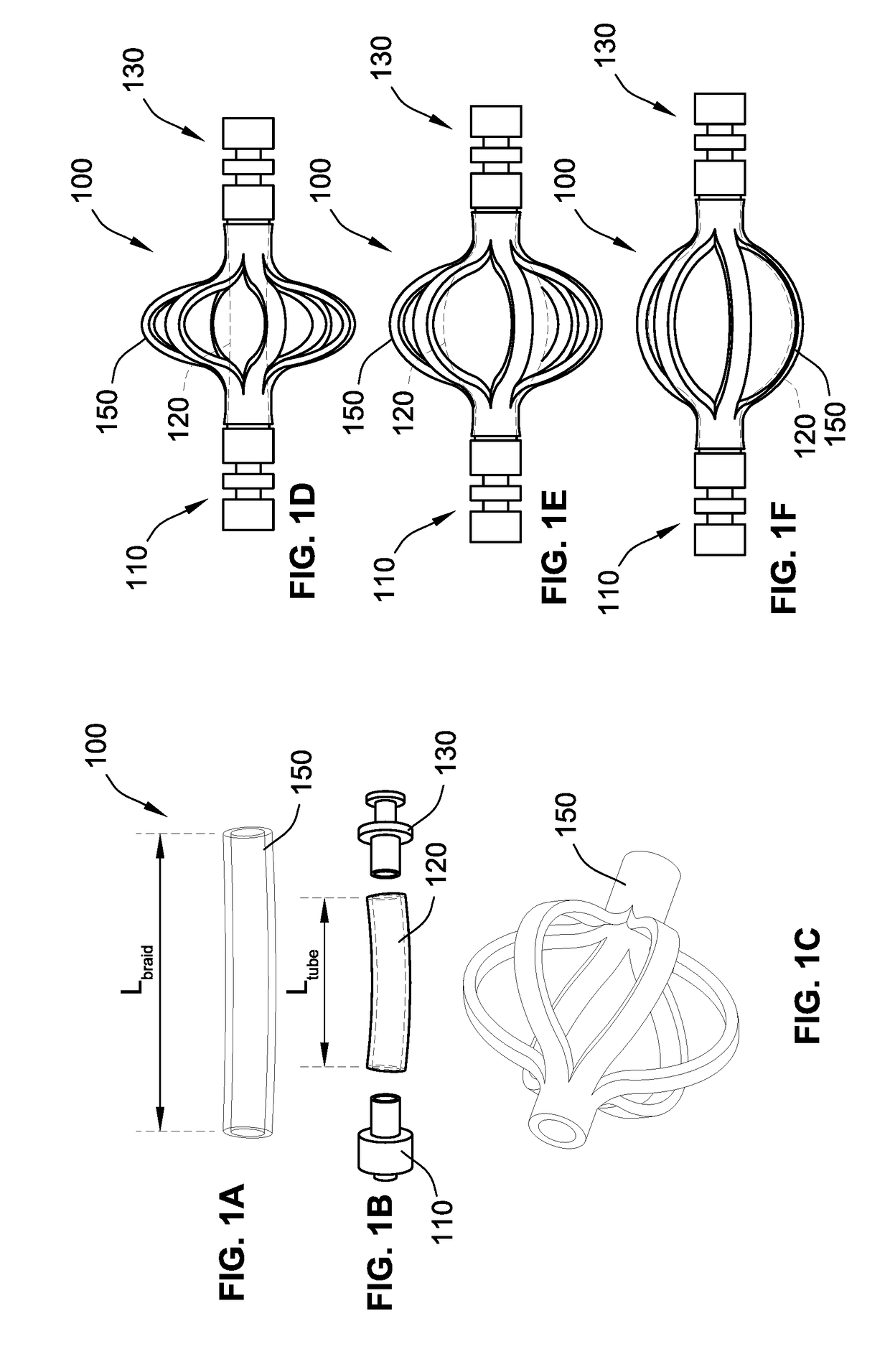

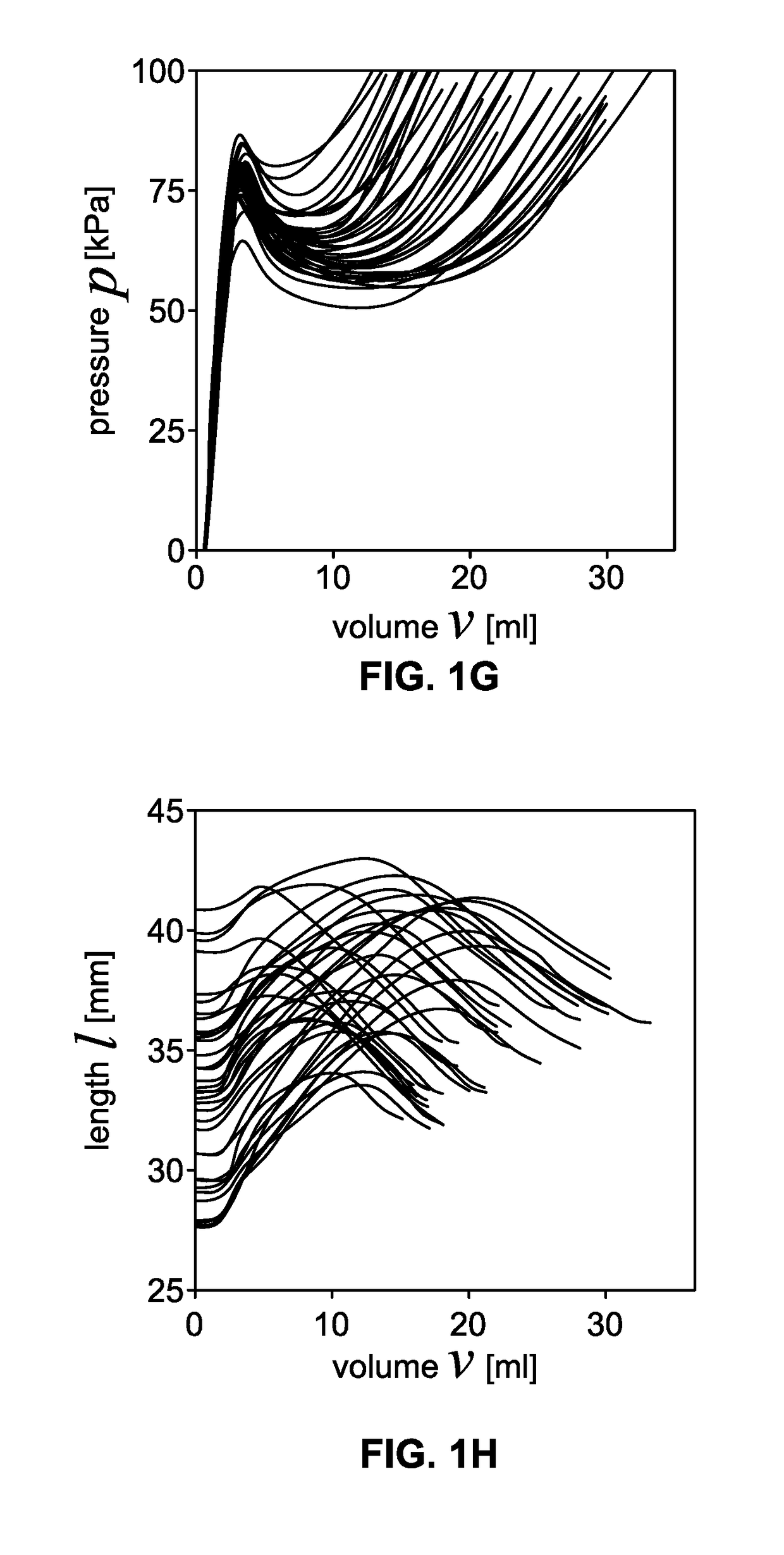

Amplifying the response of soft fluidic actuators by harnessing snap-through instabilities

In at least some aspects, there is provided a fluidic actuator including at least one fluidic actuator segment that includes an elastic tube, having a first initial length, and a braid, having a second initial length greater than the first initial length. The braid is disposed, in a buckled state, about the elastic tube and imparts an axial force to the elastic tube.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

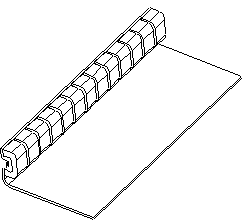

Manufacturing of airtight and waterproof zipper

InactiveCN104172678ACause damageCause water leakageSlide fastenersAgricultural engineeringHigh pressure

The invention provides manufacturing of an airtight and waterproof zipper, relating to the field of zipper manufacturing. The airtight and waterproof zipper consists of fastening tooth chain belts (1), fastening groove chain belts (2), a plurality of fastening chain teeth (3) and a plurality of fastening groove chain teeth (4), wherein the fastening chain teeth (3) are uniformly and tightly arranged on the fastening tooth chain belts (1), the fastening groove chain teeth (4) corresponding to the fastening chain teeth (3) are uniformly and tightly arranged on the fastening groove chain belts (2), and the fastening tooth chain belts (1) and the fastening groove chain belts (2) are in mutual fastened snap through the fastening chain teeth (3) and the fastening groove chain teeth (4). The airtight and waterproof zipper can have very good waterproof property at high pressure and has flexibility, the manufacturing process is simple, the sealing effect is good, and the cost is reduced.

Owner:钟能珍

Anti-arching vice

The invention relates to a clamping device. To solve the technical problem of workpiece arching caused by unevenness of a workpiece during workpiece clamping through a vice at present, the invention provides an anti-arching vice. The anti-arching vice comprises a movable jaw and a fixed jaw which are relatively fixed in a left-right mode, a sizing block is arranged on the bottom surface between the movable jaw and the fixed jaw, the movable jaw can be freely close to or far away from the fixed jaw, and the movable jaw and the fixed jaw are provided with clamping heads respectively. The anti-arching vice is characterized in that each clamping head is composed of a fixed head and a movable head, the fixed heads are fixed on the jaws, the combined surfaces of the fixed heads and the movable heads are provided with zigzag steps, the fixed heads and the movable heads are snapped through the zigzag steps, and the step surfaces of the zigzag steps of the fixed heads are provided with rubber strips. The anti-arching vice is simple in structure and convenient to use and can effectively shorten clamping time and improve labor efficiency.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

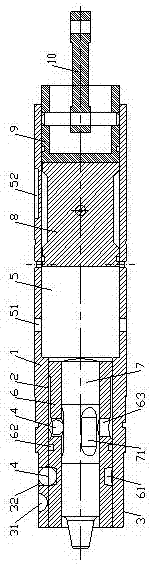

Electric hammer cylinder assembly

ActiveCN105328644BEasy to disassemble and maintainIncrease hammer strengthPortable percussive toolsSteel ballCylinder block

The invention discloses an electric hammer cylinder assembly, which includes a cylinder body. The front and rear parts of the cylinder body are respectively provided with a drill sleeve hole and a piston hole. A steel ball communicating with the drill sleeve hole is opened on the first step at the front of the cylinder body. Hole I, the outer wall ring of the first step located at the front end of the steel ball hole I is provided with a plurality of blind holes I, a drill sleeve assembly is provided in the drill sleeve hole, the drill sleeve assembly includes an impact sleeve, and the front ring of the impact sleeve is provided with a blind hole. Hole II and blind hole II are clamped with steel ball hole I through a steel ball, an impactor is arranged in the impact sleeve, a piston is arranged in the piston hole, a hammer is arranged at one end of the piston, and a connecting rod is arranged at the other end. The cylinder assembly of the present invention is shorter than the traditional cylinder assembly by adjusting the connection structure between the cylinder body and the impact sleeve, and between the cylinder body and the chuck, and is connected by steel balls to disassemble and maintain vulnerable parts It is more convenient and has a longer service life; in addition, by increasing the diameter of the piston hole, the impact force of the hammer on the drill sleeve assembly is increased, which greatly improves the working efficiency.

Owner:JIANGSU HENGFENG ELECTRIC TOOLS

Sealed secondary battery

ActiveUS10128485B2Little changeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPressure risePressure sensitive

There is provided a sealed secondary battery whose current-blocking system yields little change in the actuation pressure even on long-term use. The sealed secondary battery comprises a current-blocking system 80 that is actuated by a pressure rise inside a battery case 12 to disconnect conduction path between an electrode and an electrode terminal. Current-blocking system 80 comprises a pressure-sensitive member having a pressure-sensitive deformable portion 32 that deforms from a first state via snap-through deformation to a second state upon a pressure rise inside battery case 12, and is configured to disconnect the conduction path by snap-through deformation of pressure-sensitive deformable portion 30.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com