Manufacturing of airtight and waterproof zipper

A waterproof zipper and airtight technology, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve the problems of unsightly appearance, high cost, complicated manufacturing process, etc., and achieve simple production industry, good waterproof performance, and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

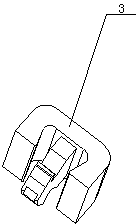

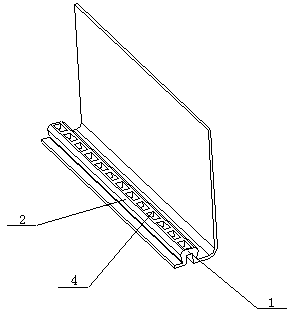

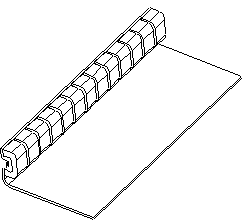

[0019] refer to Figure 1-Figure 9 , the specific implementation method adopts the following technical scheme: it is composed of a buckle chain belt 1, a buckle groove chain belt 2, a buckle type chain tooth 3, and a buckle groove chain tooth 4; There are several sprockets 4 corresponding to the sprockets 3 evenly and closely arranged on the sprocket chain belt 2, and the sprocket chain belt 1 and the sprocket chain 2 pass through the sprocket teeth 3 and the sprockets. The buckle groove chain teeth 4 are buckled and engaged with each other.

[0020] The zipper is formed by interlocking the chain teeth on two buckle chain belts 1, and the distance difference between the buckle position of the buckle chain belt 1 and the buckle chain teeth 3 is used to squeeze the buckle chain belt 1 to make the two sides close together , to achieve airtight waterproof effect.

[0021] The buckle chain belt 1 and the buckle chain tooth 3 can use different materials according to different prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com