Automotive light dimming motor

A technology for dimming motors and lights, which is applied to electrical components, electromechanical devices, electric components, etc., and can solve problems such as poor stability, shaking pins, and poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

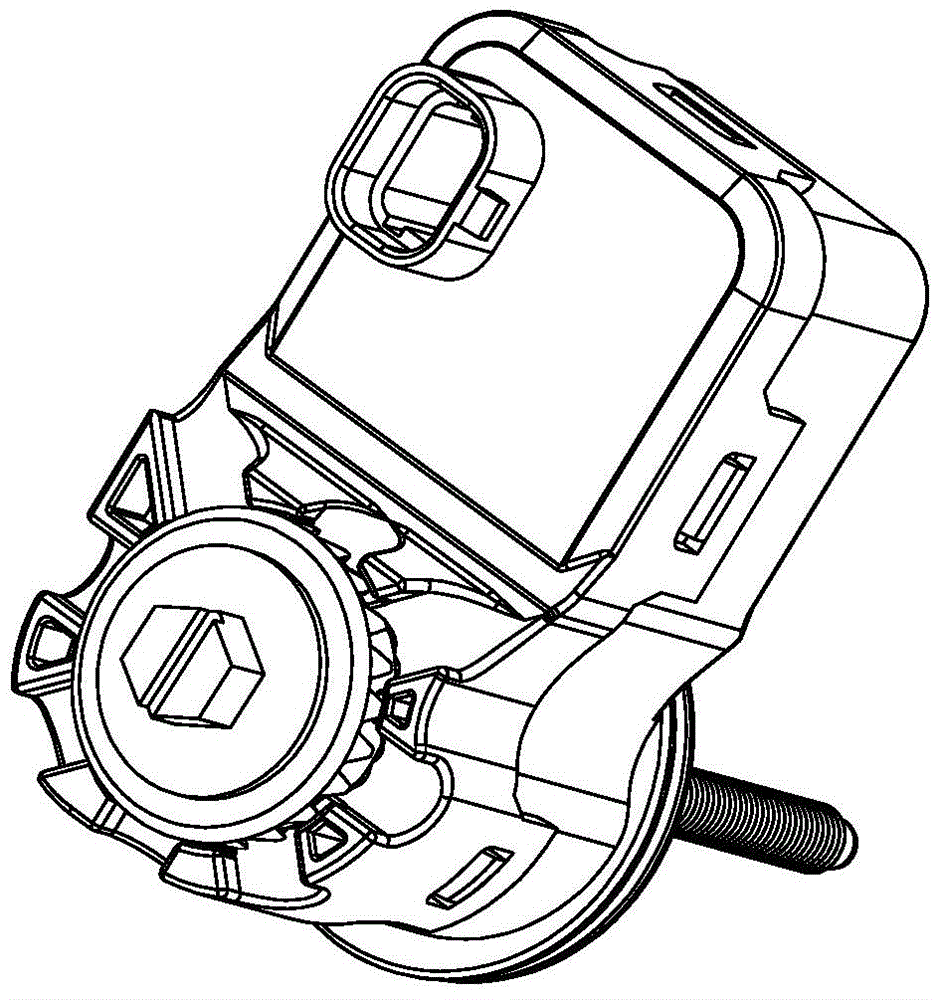

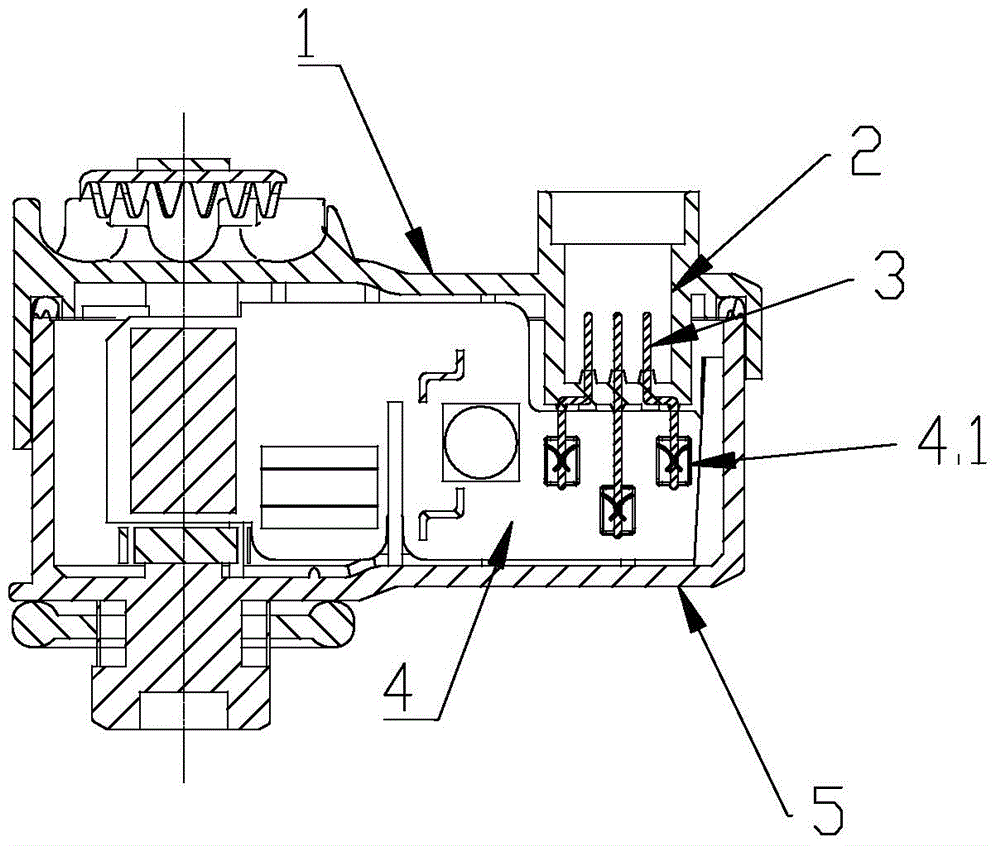

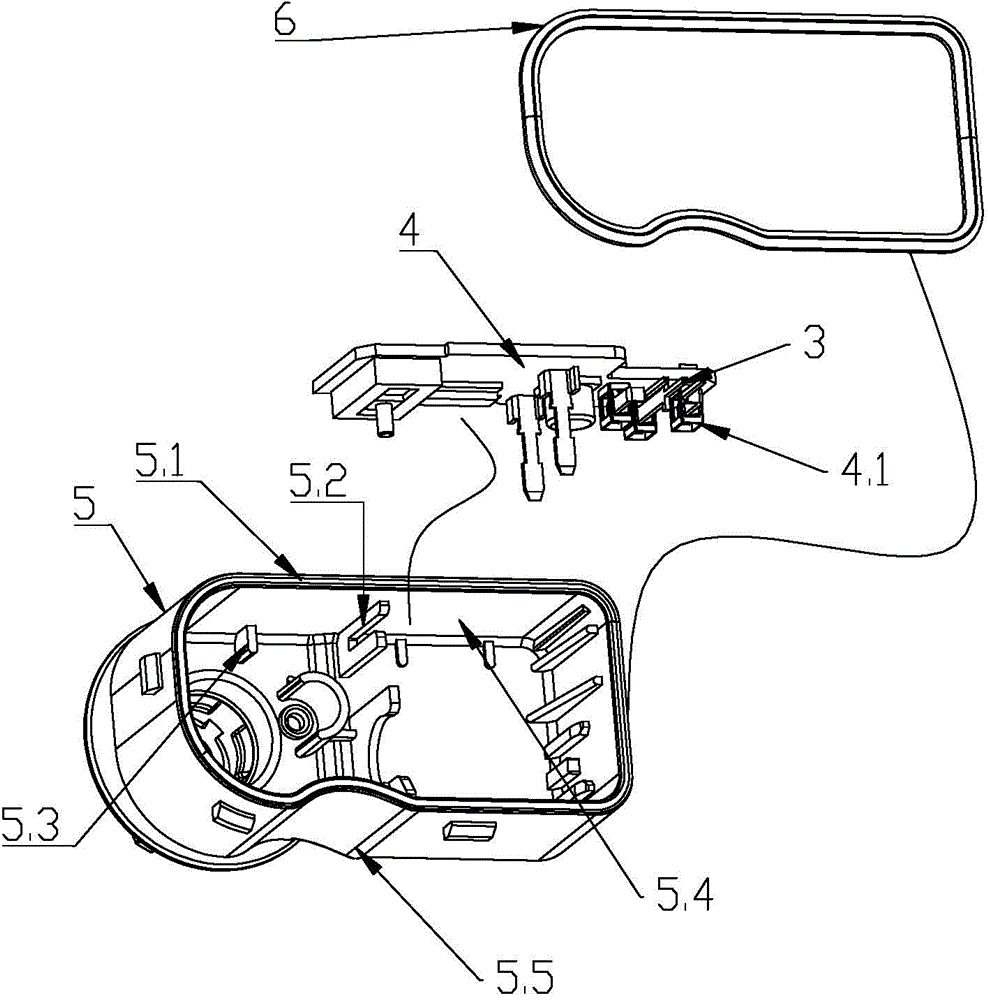

[0018] Such as Figure 1-4 As shown: the present invention proposes a dimming motor for automotive lighting, which includes an upper case 1 and a lower case 5, the upper case 1 is provided with a socket 2 for placing pins 3, and the lower case 5 is provided with a motor And the circuit board 4, the motor is not an invention point in the present invention, so the motor is omitted in the accompanying drawings, the pin 3 is injection-molded and connected to the socket 2, and the side of the circuit board 4 is provided with a tail for connecting with the pin 3. end-connected elastic socket 4.1, the tail end of the pin 3 is plugged into the elastic socket 4.1, the circuit board 4 is parallel to the inner surface 5.4 of the lower shell 5, and the inner surface 5.4 of the lower shell 5 is also There is a card seat 5.2 for clamping the circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com