Snap-in connection for pumping plunger sliding shoes

A technology of plunger and pump pressure, applied in the direction of components, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems such as difficult, difficult to assemble, and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

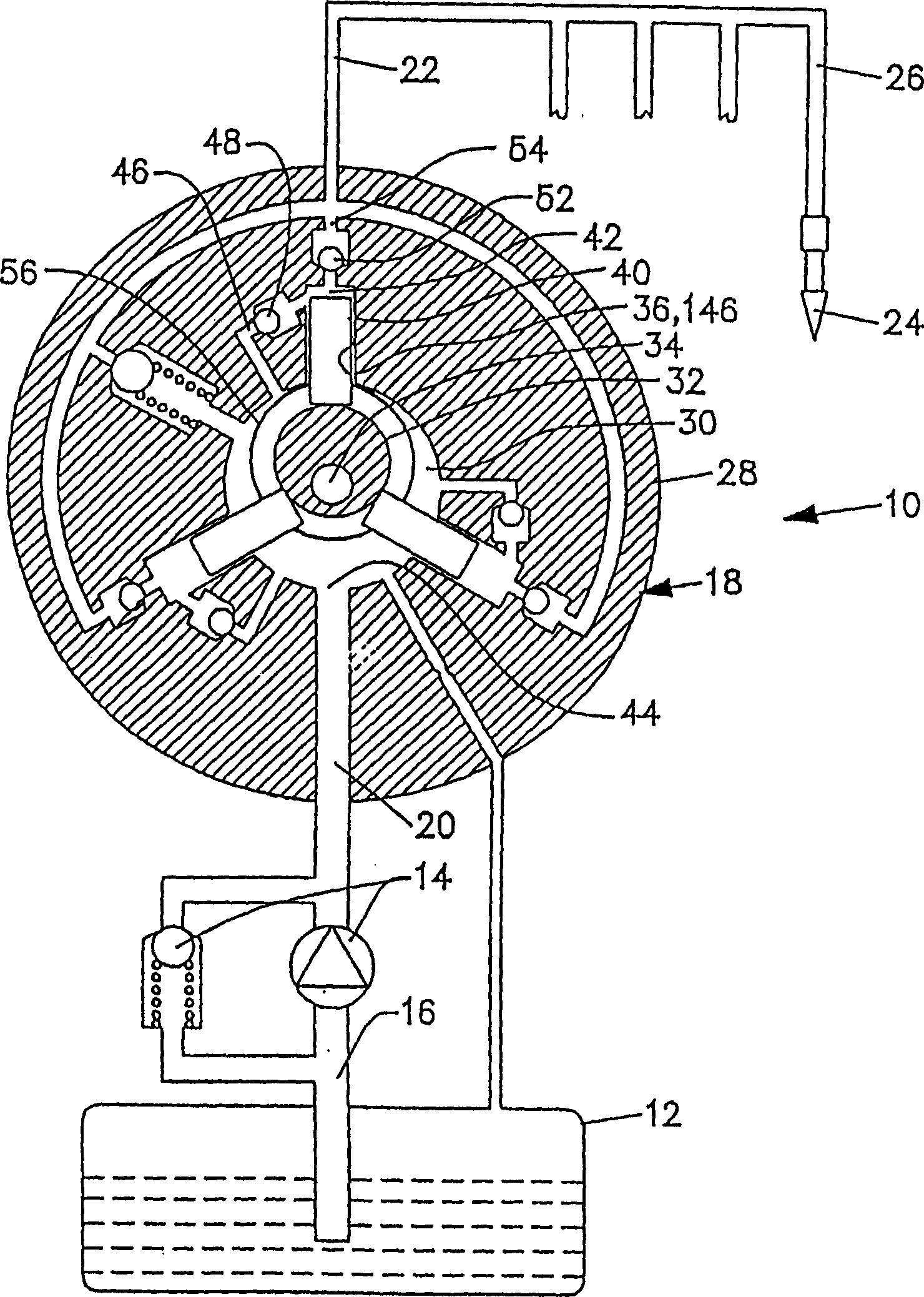

[0044] figure 1 is a schematic illustration of a fuel injection system 10 comprising a fuel tank 12 and a feed pump 14 fitted with a low pressure regulator for delivering fuel via a low pressure fuel line or suction line 16 to an internally driven feed pump 18 . Fuel from feed pump 14 enters feed pump 18 through an inlet port or passage 20 where the fuel builds up pressure. High pressure fuel is discharged into an external manifold 22 for delivery to a plurality of fuel injectors 24 each fueled by a fuel injector manifold 26 . Alternatively, the pump 18 may directly supply oil to the branch pipe 26 (not shown in the figure).

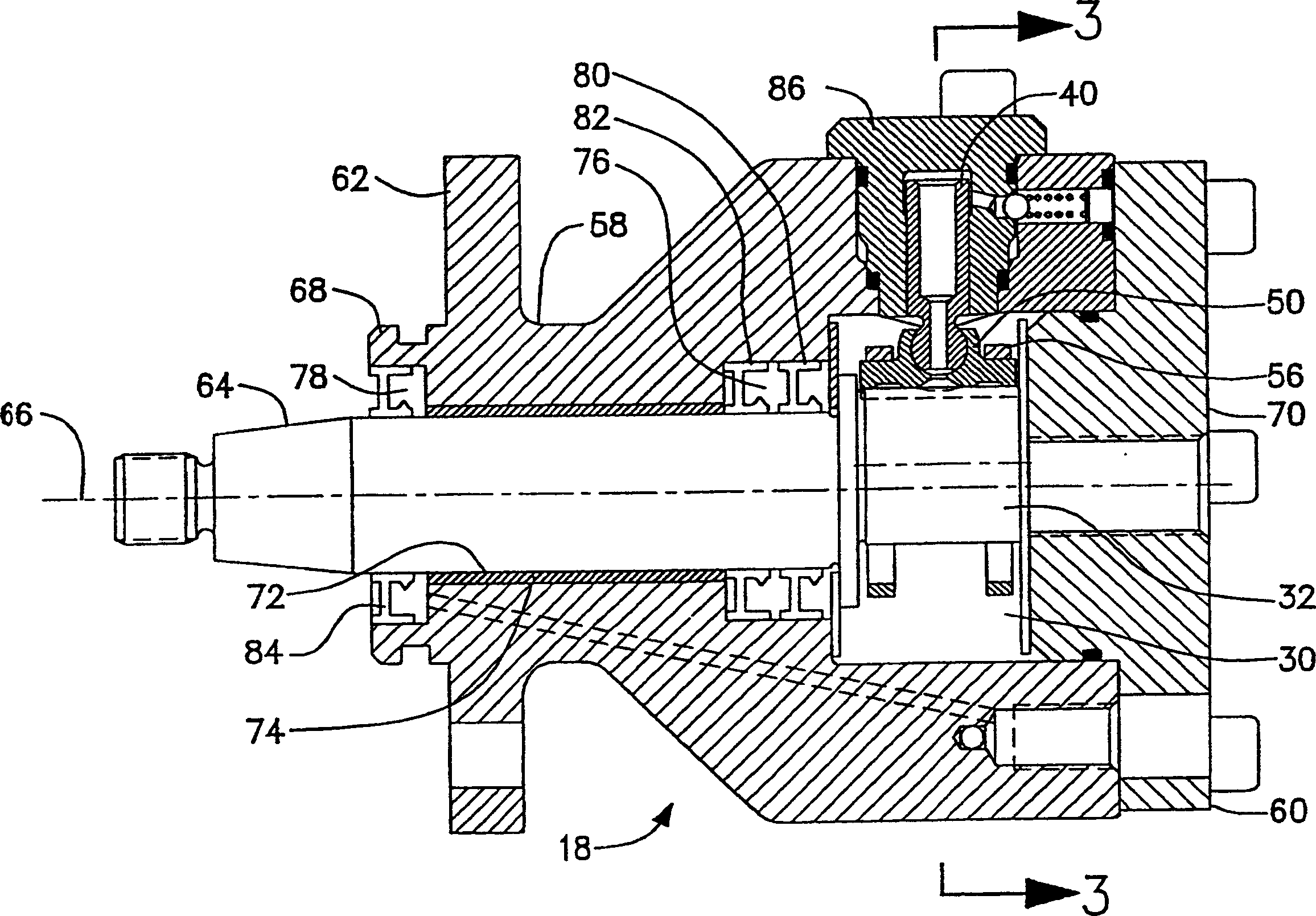

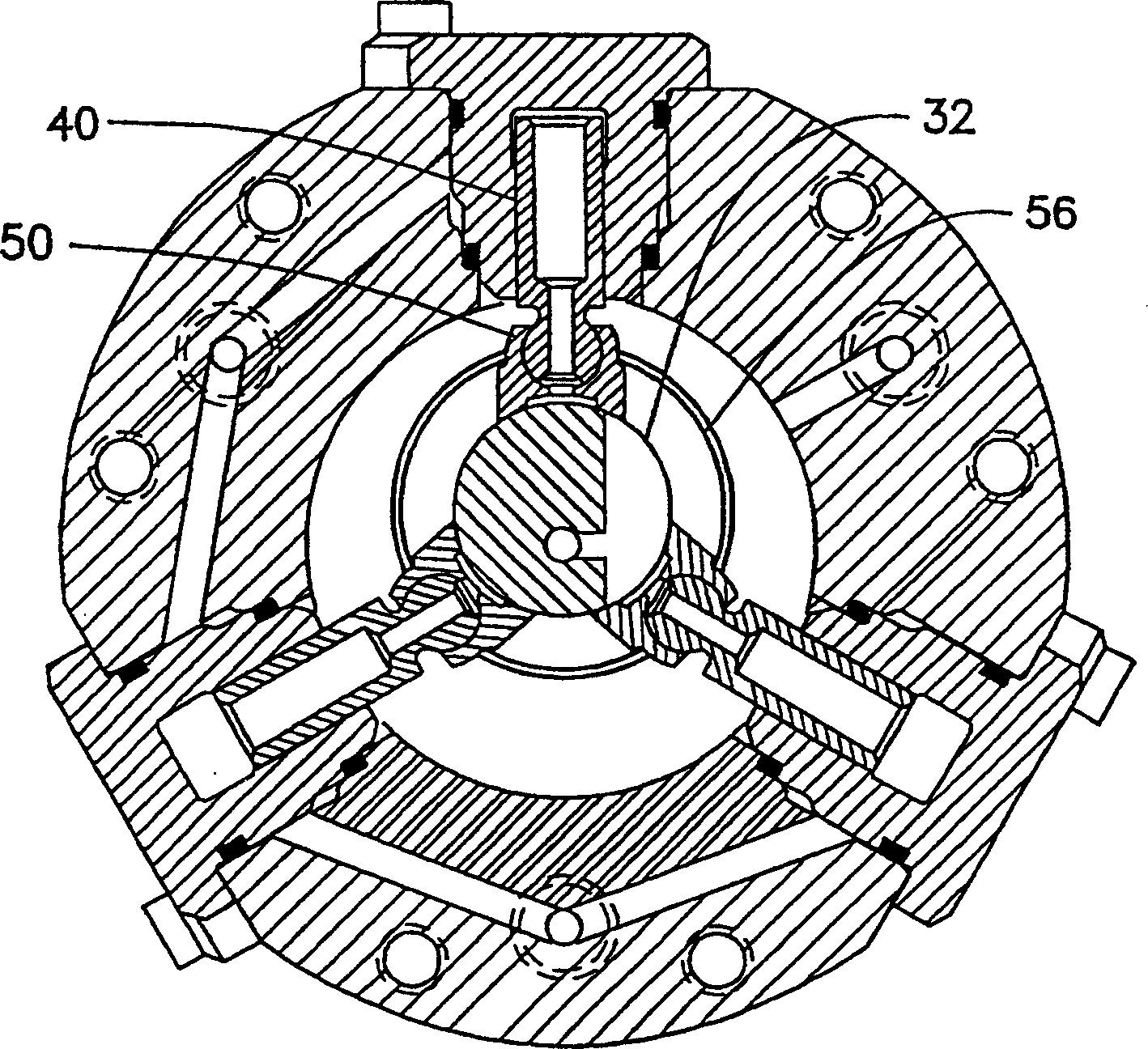

[0045] The internally driven fuel supply pump 18 consists of a pump housing 28 and an inner chamber 30 into which low-pressure fuel is fed through the fuel supply passage 20 . An eccentric drive member 32 is rotatable within cavity 30 about drive shaft 34 to increase fuel pressure in the manner described below. A plurality of plunger cylinders 36 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com