Electric hammer cylinder assembly

A technology of air cylinder and electric hammer, which is applied in the direction of impact tools, light impact tools, manufacturing tools, etc. It can solve the problems of reducing the service life of auxiliary parts, the impact force of the hammer is not strong enough, and the process is cumbersome. Convenient parts, improve work efficiency, and improve the effect of hammering force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

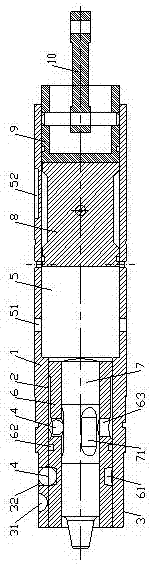

[0012] Such as figure 1 As shown, the electric hammer cylinder assembly includes a cylinder block 1. The front part of the cylinder block 1 is provided with a drill bushing hole 2, and the rear part is opened with a piston hole 5 communicating with the drill bushing hole 2. The first part of the front part of the cylinder block 1 There is a steel ball hole I32 connected to the drill sleeve hole 2 on the step 3, and the outer wall ring of the first step 3 located at the front end of the steel ball hole I32 is provided with a plurality of blind holes I31, preferably 4; A drill sleeve assembly is provided, and the drill sleeve assembly includes an impact sleeve 6. An annular groove 62 is provided on the outside of the impact sleeve 6. The impact sleeve 6 is divided into front and rear parts through the annular groove 62. The front ring of the impact sleeve 6 is provided with There is a blind hole II61, and the blind hole II61 is clamped with the steel ball hole I32 through the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com