Construction method for concrete macrotype xenotype shell construction body

A construction method and concrete technology, which is applied to arch structures, dome structures, building components, etc., can solve the problems that cannot give special-shaped concrete structure space coordinates and control equations, formwork production, support and concrete pouring difficulties, special-shaped Complicated appearance of concrete structures and other issues, to achieve good social and economic benefits, safe construction, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

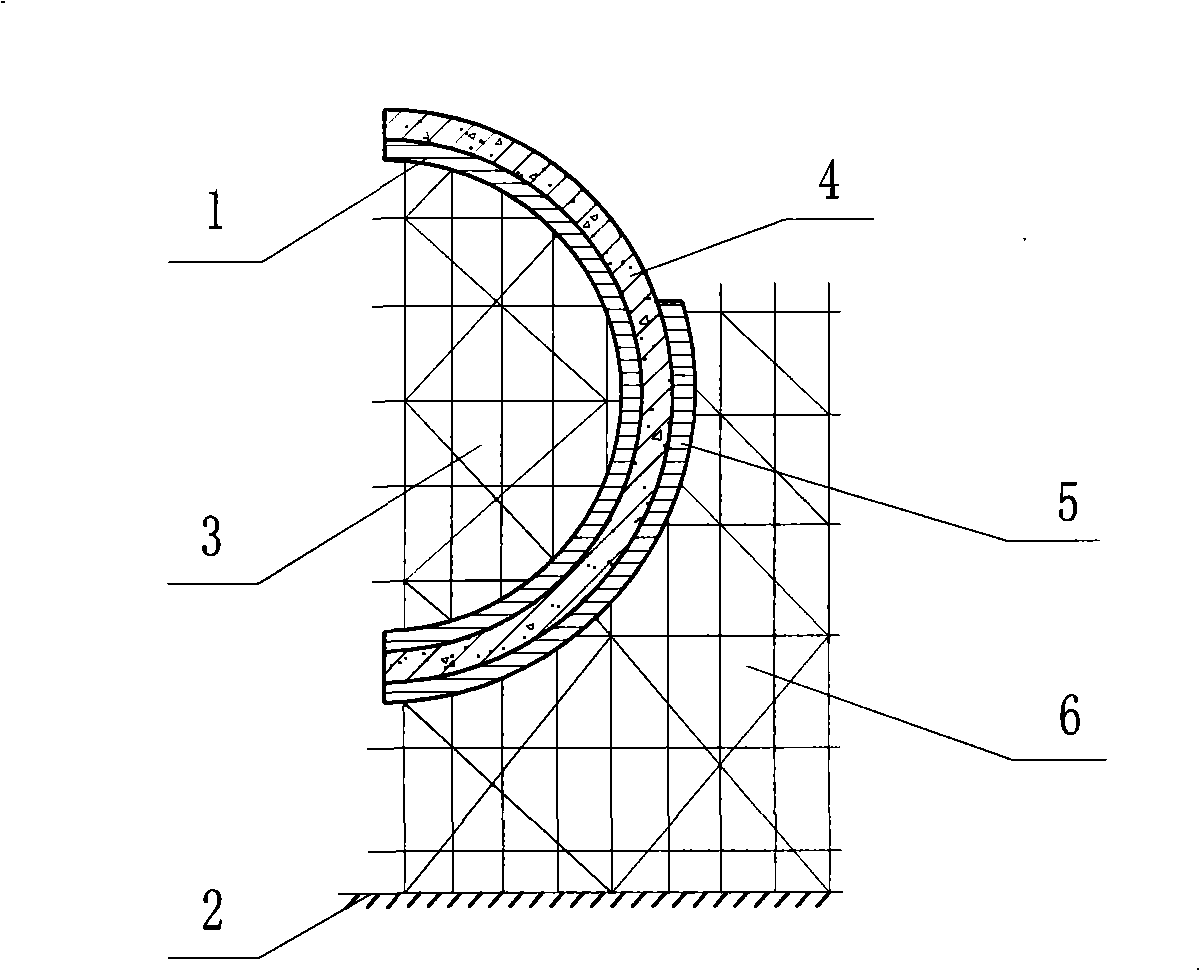

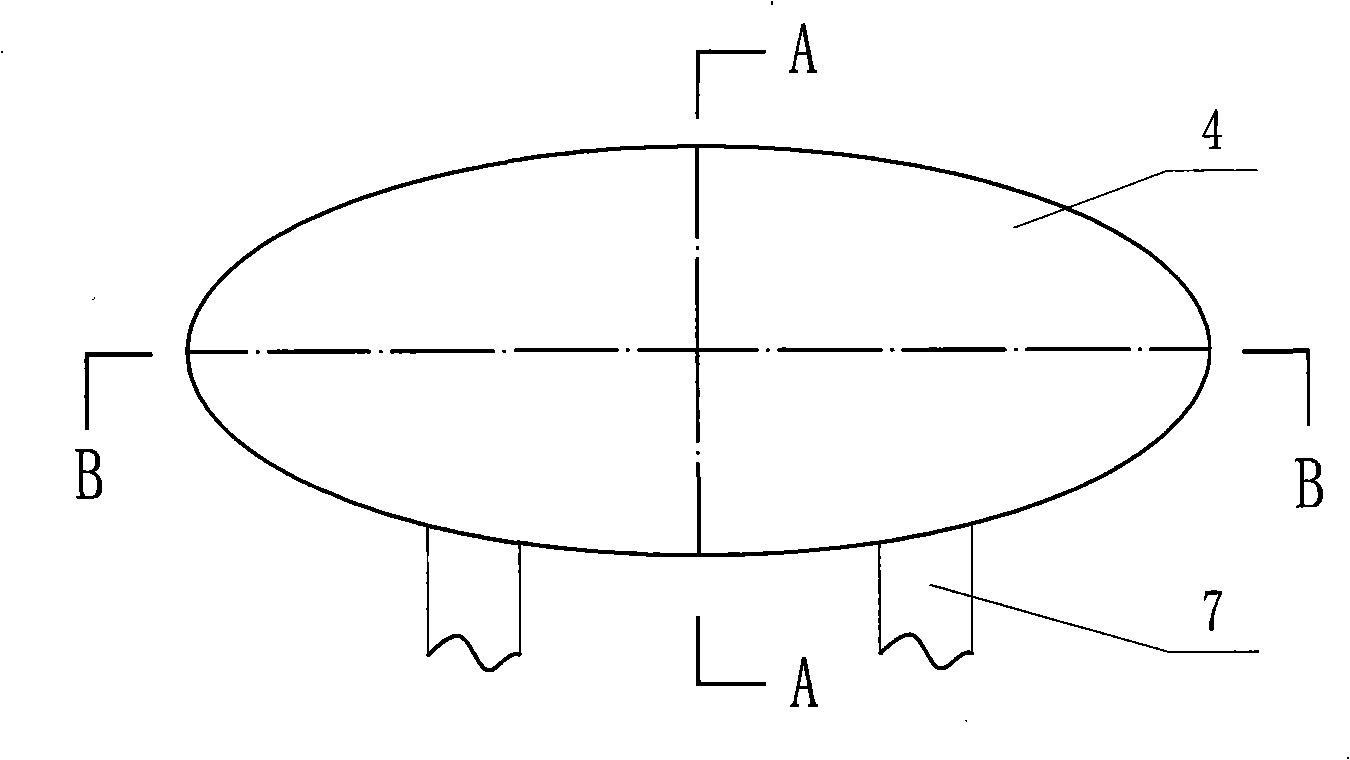

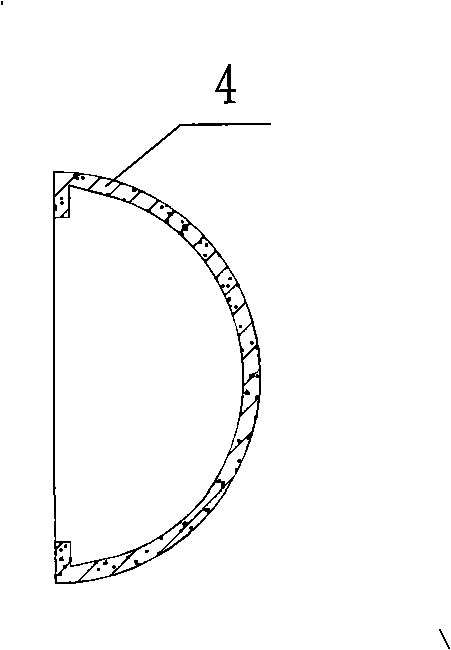

[0032] Example: see Figure 1 ~ Figure 4 , in the figure, the shape of the concrete large special-shaped thin shell structure is a semi-elliptical shell, which is used to make the olive-shaped scoreboard of the stadium. The construction method includes the following steps:

[0033] (1) Production of FRP outer mold

[0034] a. According to the shape control size of the concrete large-scale special-shaped thin-shell structure given in the construction drawing, pile soil to make the tire mold prototype 8, the surface shape of the tire mold prototype 8 is controlled by the lofting data, and the reinforcement positioning is made according to the lofting data of each cross section To control the surface elevation of the piled soil, a layer of bricks 9 is tiled on the surface of the tire mold prototype 8, and the surface is trimmed and shaped according to the design requirements, and then the surface is powdered with cement mortar (the proportion of cement and sand in the cement mort...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com