Vehicle body based on truss skeleton thin shell structure of composite load bearing type base board

A thin-shell structure, load-bearing technology, applied in the direction of load-bearing body structure, superstructure, vehicle parts, etc., can solve the problems of affecting the driving stability of the vehicle, large amount of plate materials, and large body mass, etc. Height and centroid height, convenient production and processing, and the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

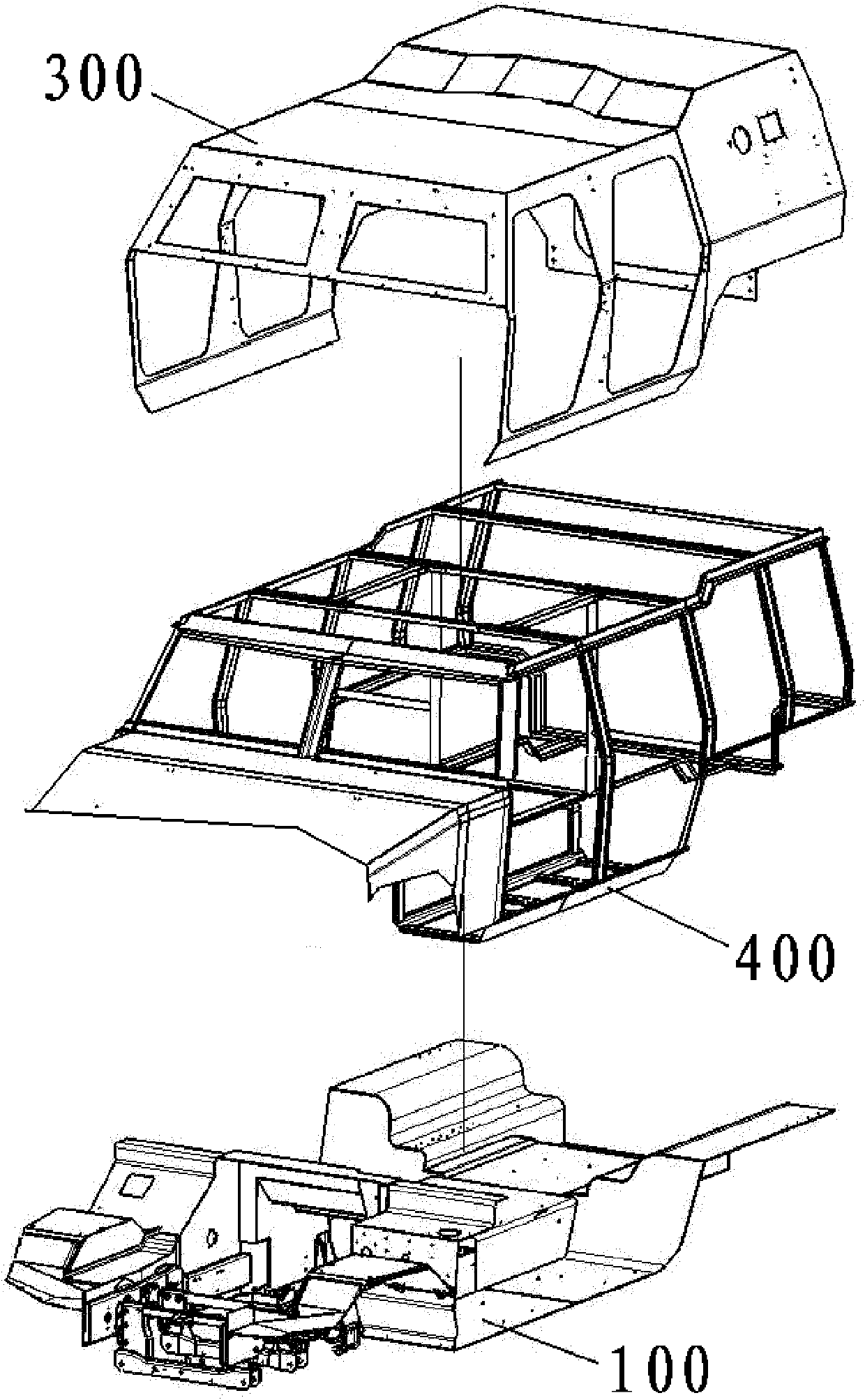

[0034] Such as figure 1 As shown, the car body of this embodiment is composed of a full-protection load-bearing base plate 100, a skeleton 400 of a vehicle body truss structure connected to the full-protection load-bearing base plate 100, and a body welded and spliced by plates connected to the frame 400 of the vehicle body truss structure The casing 300 constitutes.

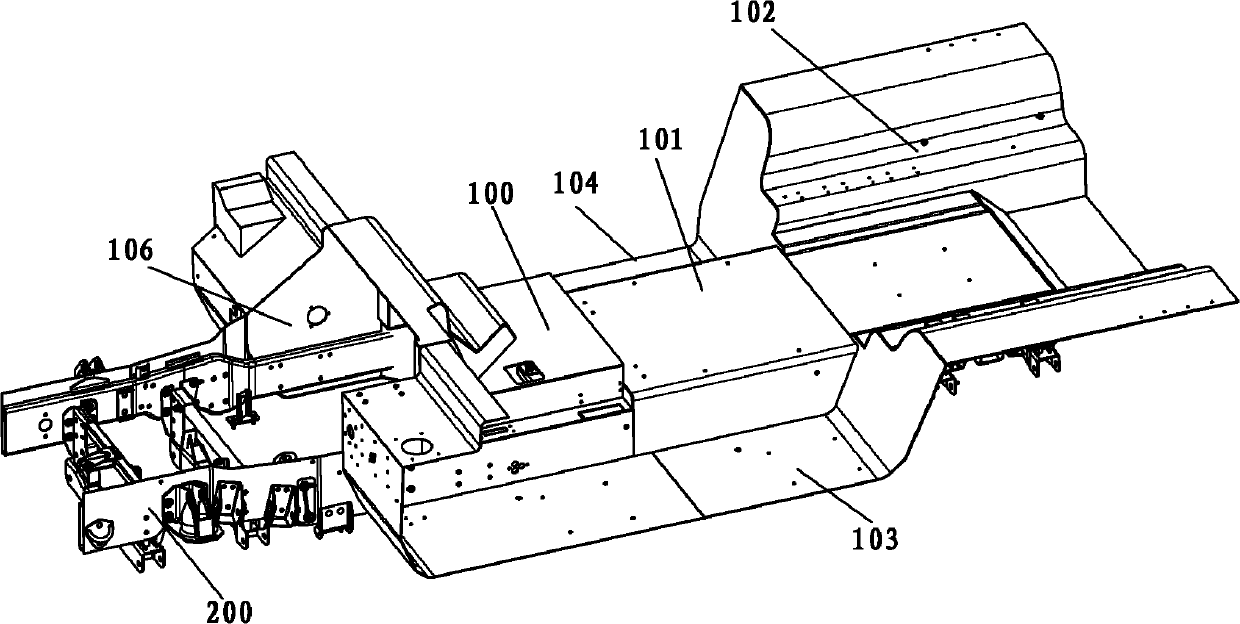

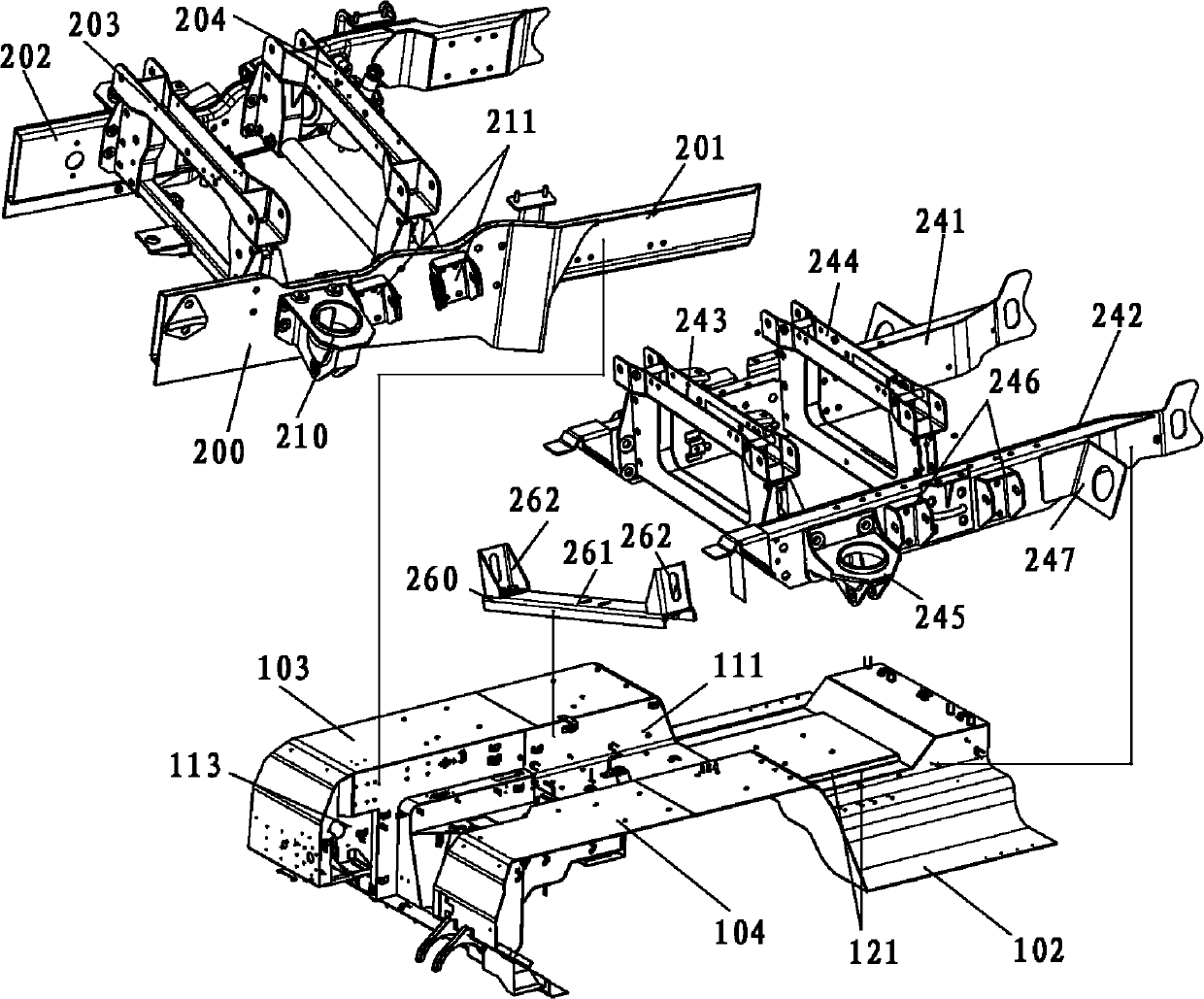

[0035] Such as figure 2 As shown, the structure of the base plate 100 includes a floor composed of panels, under which suspension mounting brackets are connected.

[0036] The floor includes a front floor 101, a rear floor 102 is arranged behind the front floor 101, and the two sides of the front floor 101 are connected with the left and right floors 103, 104; The both sides of 101 are provided with side plate 105,106 ( figure 2 , 5 As shown), the side panels 105, 106 are connected to the left and right floor panels 103, 104 respectively. In this way, a height difference is formed between the front floo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com