Method and device for measuring temperature and heat flow distribution on internal face of combustion chamber

A technology of heat flow distribution and measuring device, which is applied in the direction of measuring device, thermometer parts, thermometer, etc., to achieve the effect of wide application range, convenient use, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

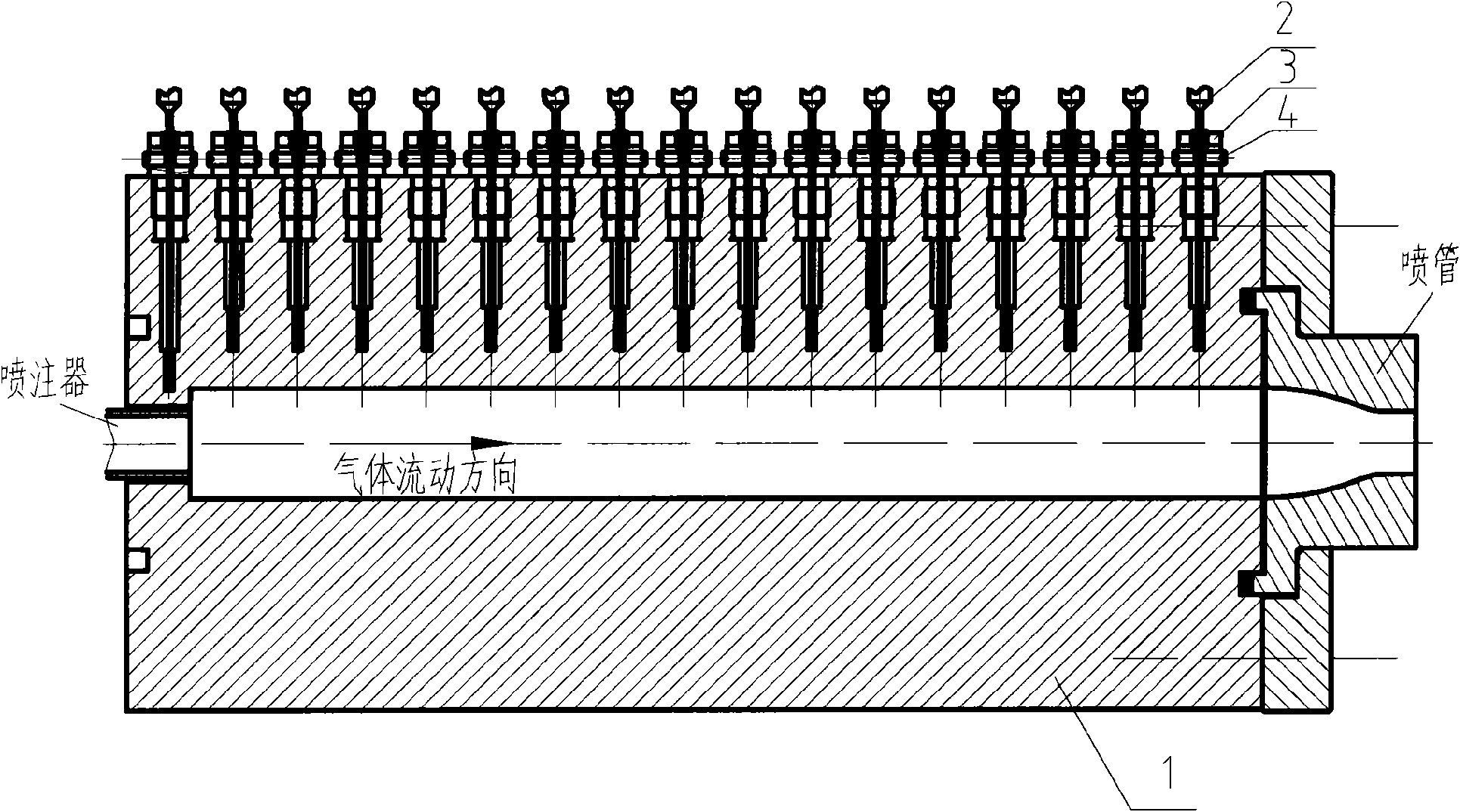

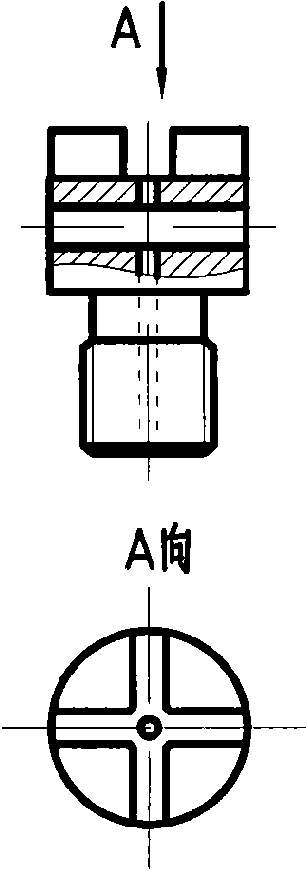

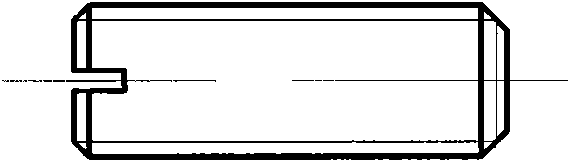

[0022] The device used to implement this measurement method mainly includes: a combustion chamber body 1 with a temperature measuring hole, a thermocouple temperature sensor 2 and a thermocouple fixing device (comprising a fastening nut 3 and a fastening screw 4). Before the experiment, extend the thermocouple probe into the temperature measuring hole, make the probe closely contact with the temperature measuring point on the solid wall, and fix the position of the thermocouple with the thermocouple fixing device. The temperature of each measuring point inside the combustion chamber wall can be collected during the experiment.

[0023] Such as figure 1 As shown, the temperature measuring holes are arranged in a straight line along the axial direction. Except for the temperature measuring point on the head, the depth, diameter and structure of each temperature measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com