Processing control method of axial symmetry free-form surface of aspheric surface optical elements

An optical element, axisymmetric technology, applied in the field of aspherical optical elements, can solve the problems of difficult processing and high cost, and achieve the effects of convenient operation, simple installation and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

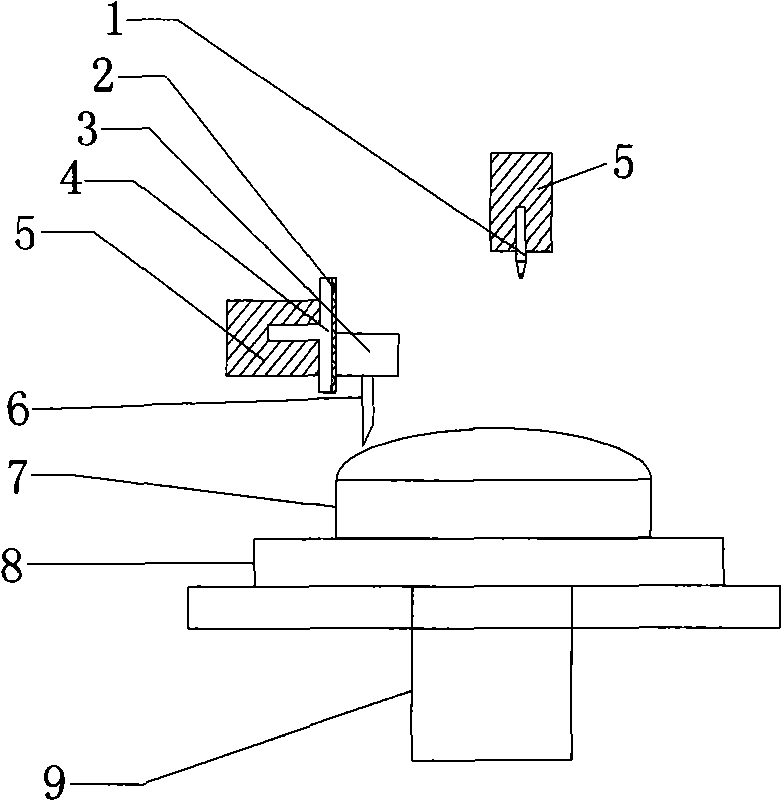

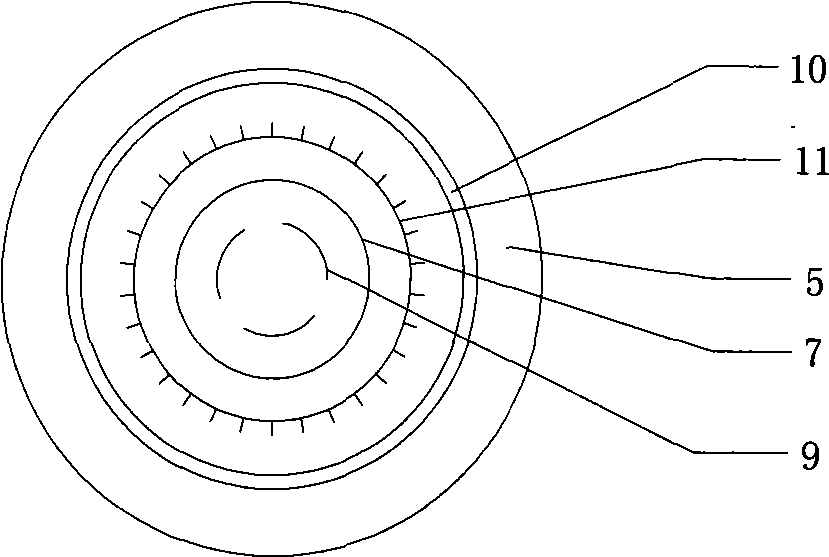

[0025] Figure 1~3 The codes of the main components in:

[0026] 1 laser interferometer, 2 micro-feed mechanism, 3 grating scale, 4 tool holder, 5 worktable, 6 turning tool, 7 workpiece, 8 rotating platform, 9 spindle, 10 chute, 11 rotary encoder.

[0027] see figure 1 with 2 , the workpiece 7 to be processed is fixed on the rotary platform 8, and the rotary platform 8 is connected with the main shaft 9 to perform high-speed rotary motion. The laser interferometer 1 and the tool rest 4 are all installed on the workbench 5, and the tool rest 4 moves up and down along with the workbench 5 during the processing (such as figure 1 indicated by the double-headed arrow in the vertical direction). Have chute 10 on the workbench 5. The knife rest 4 is located in the chute 10 , and the knife rest 4 can slide along the chute 10 , and a rotary encoder 11 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com