Combined type bidirectional moving intelligent garage carrying robot

A handling robot, two-way motion technology, applied in the field of handling robots, can solve the problems of reducing the service life of tires, uneven contact, uneven stress changes of tire contact surfaces, etc., to increase safety and reliability, and avoid eccentric load and shaking. , the effect of safe parking services

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

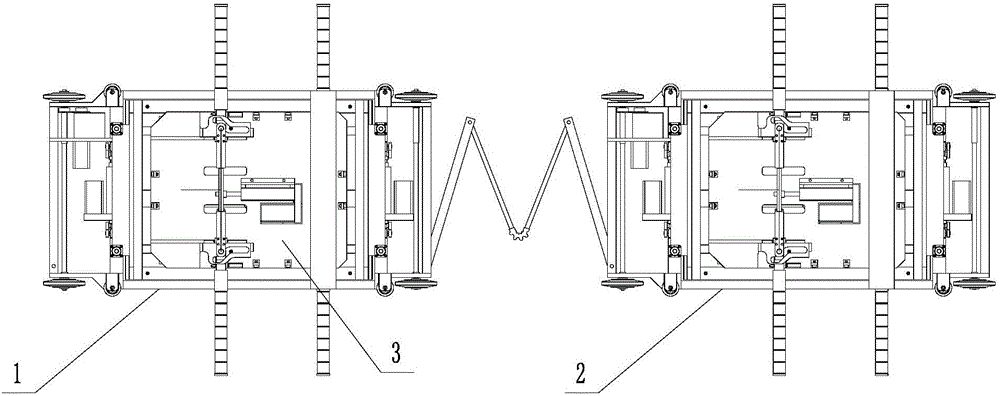

[0039] A combined two-way moving intelligent garage handling robot provided in this embodiment includes a first dolly 1 and a second dolly 2 for vehicle handling, and the first dolly 1 is provided with a walking mechanism for driving the dolly to move back and forth. A sliding elimination mechanism for eliminating vehicle parking deviation, a lifting mechanism for lifting the vehicle, and a clamping mechanism for clamping vehicle tires;

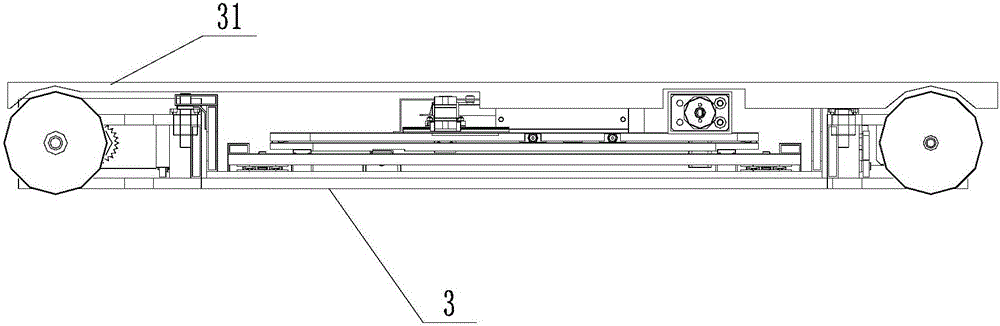

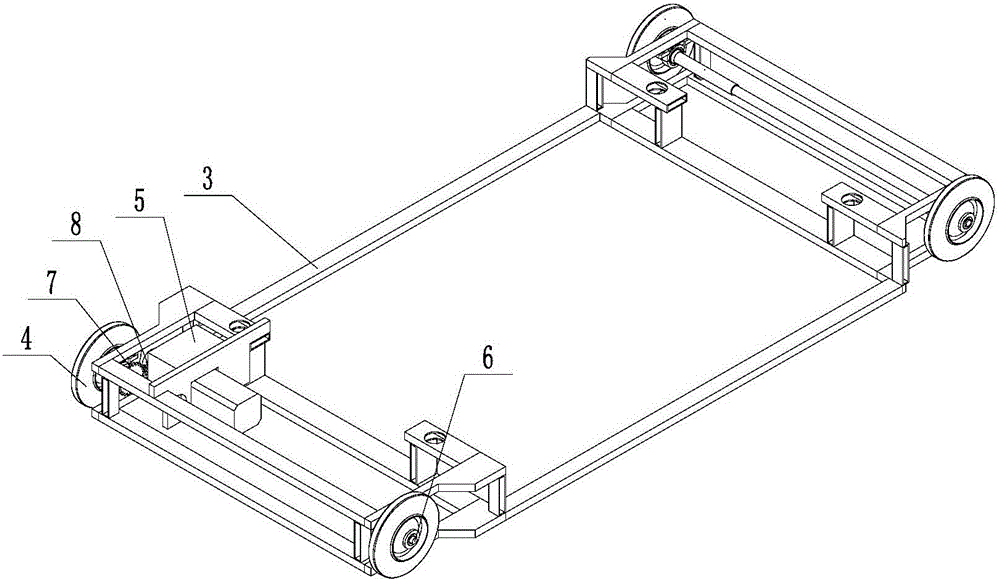

[0040] The traveling mechanism comprises a chassis 3 arranged horizontally, a walking wheel 4 installed on the side of the chassis 3, a traveling motor 5 arranged on the chassis 3, one end along the length direction of the chassis 3 is a driving end, and the other end is a driven end, and at the driving end Be provided with travel motor 5, travel wheel 4 is fixed on the chassis 3 by main shaft 6, and be provided with first gear 7 on the main shaft 6 that is positioned at driving end, the output end of travel motor 5 is provided with the second...

Embodiment 2

[0054] A combined two-way moving intelligent garage handling robot provided in this embodiment includes a first dolly 1 and a second dolly 2 for vehicle handling, and the first dolly 1 is provided with a walking mechanism for driving the dolly to move back and forth. A sliding elimination mechanism for eliminating vehicle parking deviation, a lifting mechanism for lifting the vehicle, and a clamping mechanism for clamping vehicle tires;

[0055] The traveling mechanism comprises a chassis 3 arranged horizontally, a walking wheel 4 installed on the side of the chassis 3, a traveling motor 5 arranged on the chassis 3, one end along the length direction of the chassis 3 is a driving end, and the other end is a driven end, and at the driving end Be provided with travel motor 5, travel wheel 4 is fixed on the chassis 3 by main shaft 6, and be provided with first gear 7 on the main shaft 6 that is positioned at driving end, the output end of travel motor 5 is provided with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com