Mechanical arm motion control system

A technology of motion control system and robotic arm, applied in the direction of manipulator, program control manipulator, claw arm, etc., can solve the problem that the control accuracy of the manipulator is difficult to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

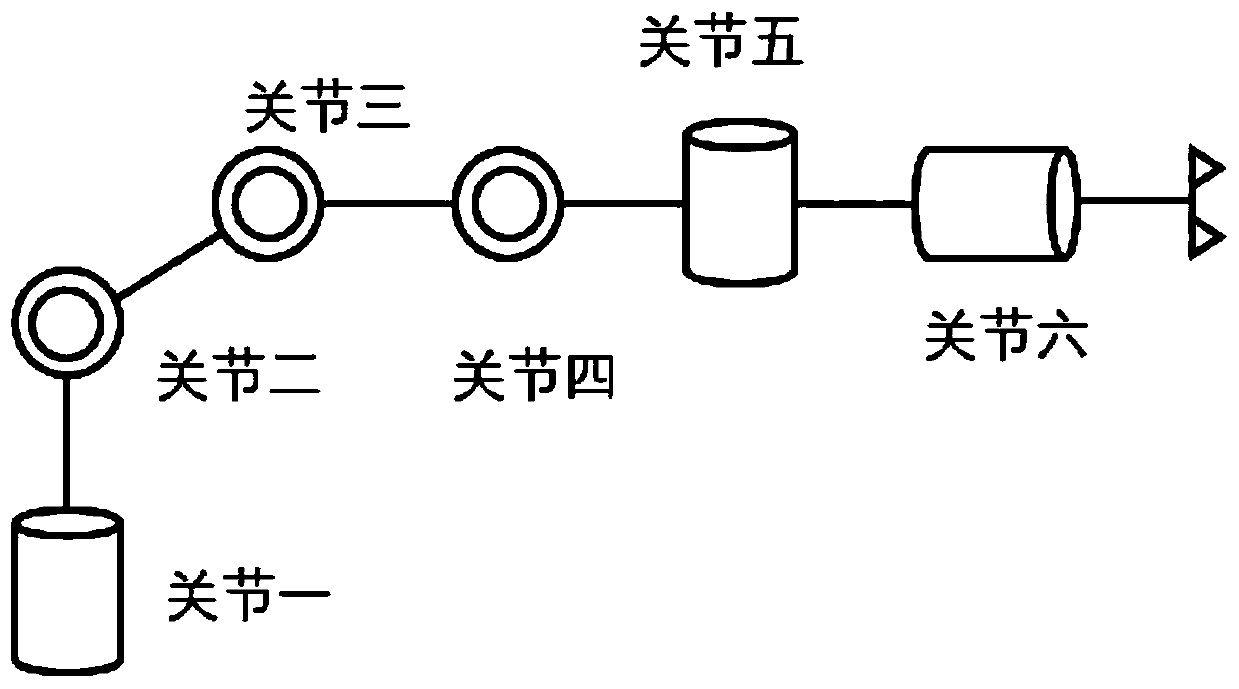

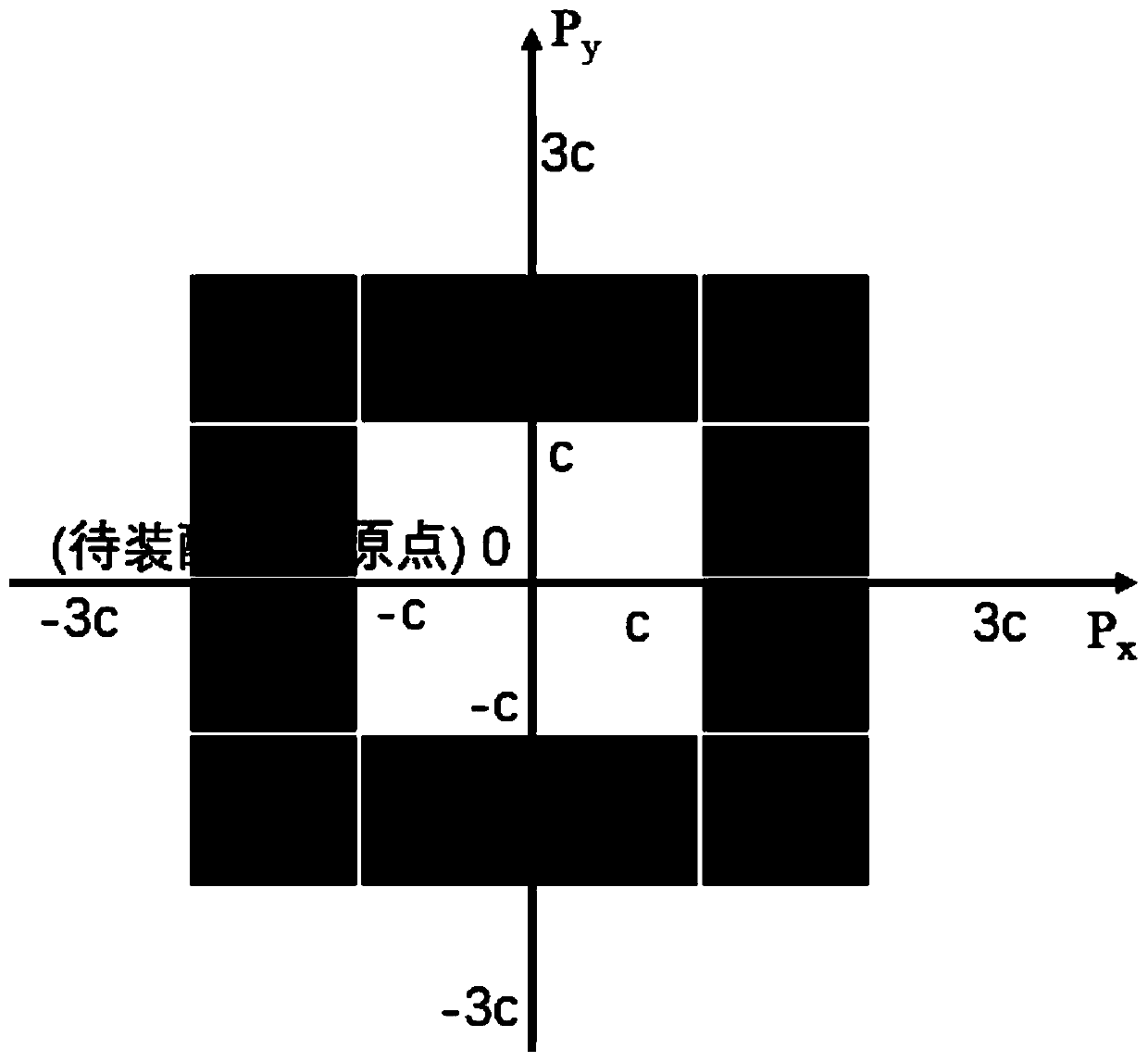

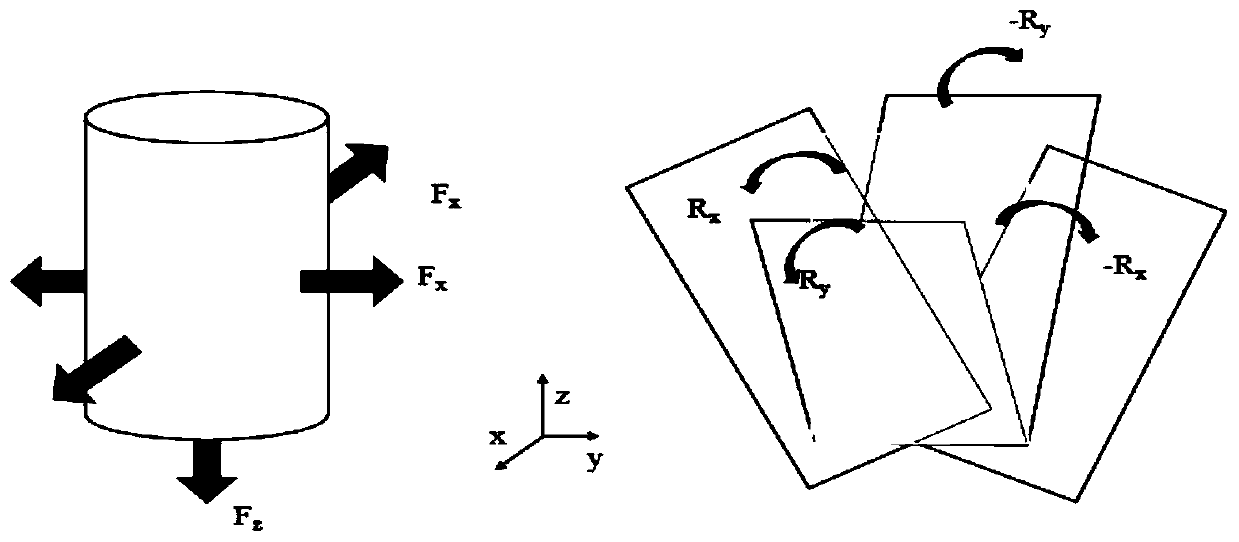

[0063] This embodiment provides a motion control system for a manipulator, which includes an intelligent compliant assembly platform, a moving assembly workpiece, and a stationary assembly workpiece, wherein: figure 1 As shown, the intelligent compliant assembly platform controls a six-degree-of-freedom collaborative manipulator, and the six-degree-of-freedom collaborative manipulator includes an end effector, and the intelligent compliant assembly platform generates state information of the six-degree-of-freedom collaborative manipulator; The intelligent compliant assembly platform establishes a training model according to the state information of the six-degree-of-freedom collaborative manipulator, realizes drag teaching and collision detection, and obtains force control algorithms and search assembly algorithms; the six-degree-of-freedom collaborative manipulator implements force control The algorithm and the search assembly algorithm arrive at the designated station, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com