Assembling and detecting method for cable with terminal and a plastic housing

A detection method and cable technology, applied in the field of machinery, can solve problems such as lighting up, affecting the production efficiency of fluorescent lamps, and affecting the qualification rate of lamp head components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific structure and operation process of the present invention will be further described below in conjunction with the accompanying drawings.

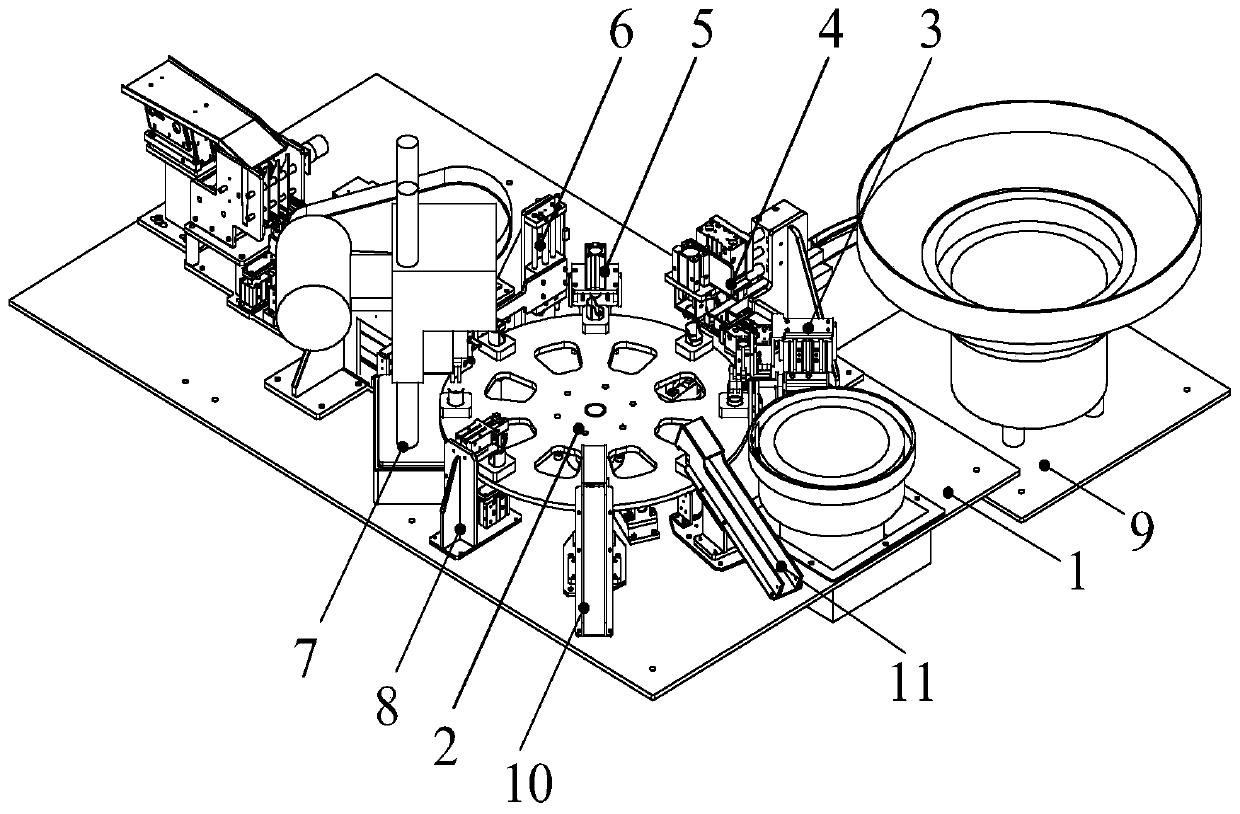

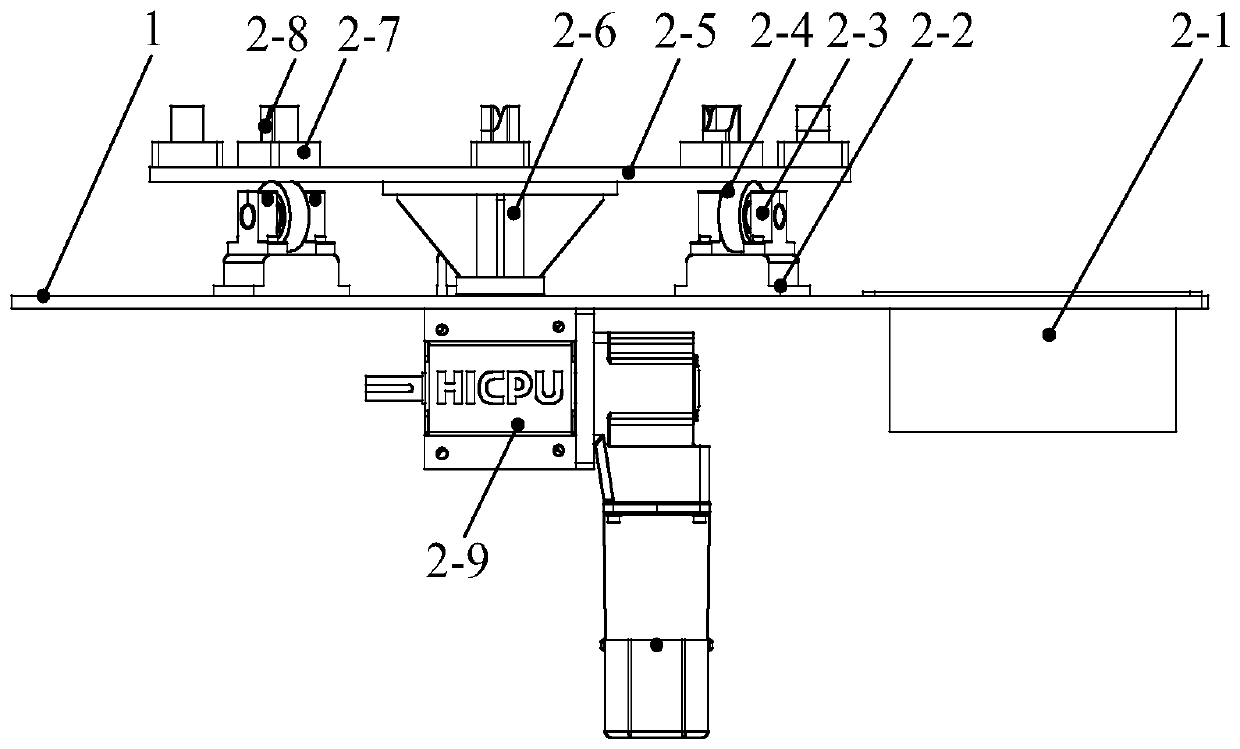

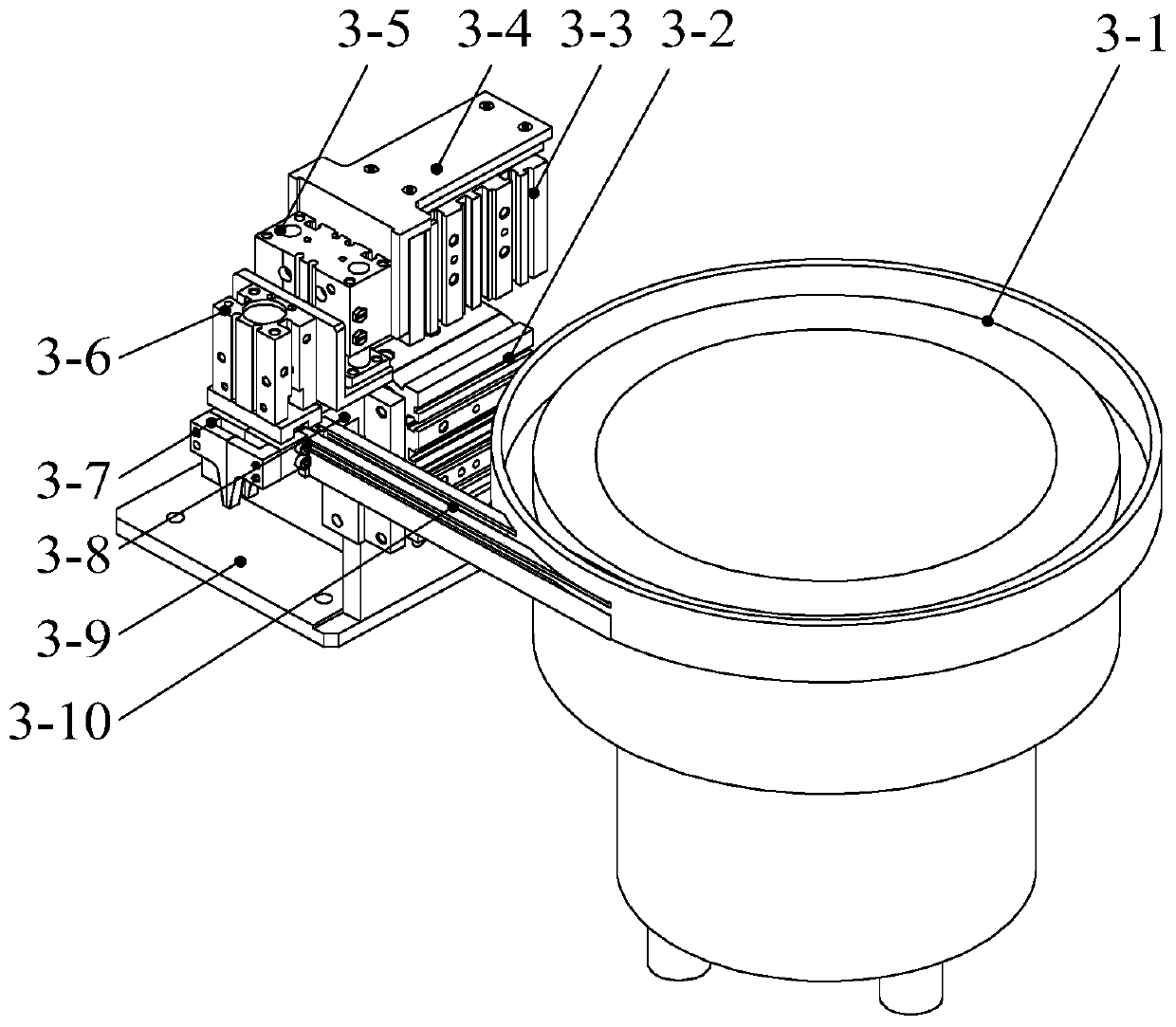

[0050] like figure 1 As shown, the assembly and detection device of the cable with terminals and the plastic case adopted in the present invention includes a large platform 1, a large turntable mechanism 2, a needle dropping mechanism 3, a shell dropping mechanism 4, a shell pressing mechanism 5, a wire feeding assembly 6, a stamping Mechanism 7, finished product testing mechanism 8, small platform 9, waste product discharging mechanism 10 and finished product discharging mechanism 11; the stamping mechanism adopts an electric punch press model of Shuangwei brand JB04-1.5T. Needle dropping mechanism 3, shell dropping mechanism 4, shell pressing mechanism 5, wire feeding assembly 6, punching mechanism 7, finished product testing mechanism 8, waste product discharging mechanism 10 and finished product discharging mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com