Hot-melt field-assembled optical fiber connector

A fiber optic connector and on-site assembly technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of poor performance of optical fiber quick connectors, and achieve the effects of saving on-site assembly time, improving assembly success rate, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

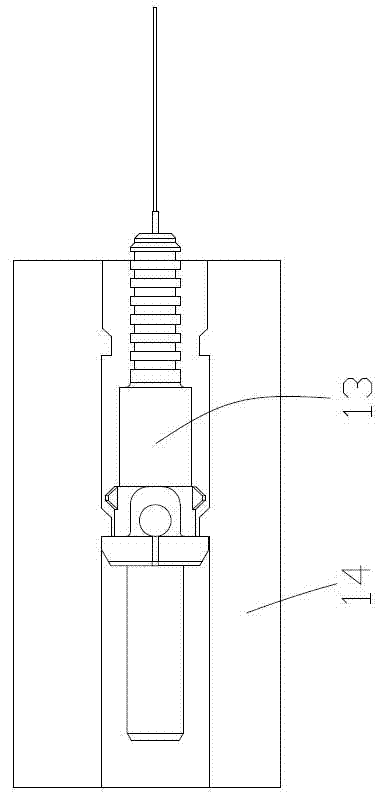

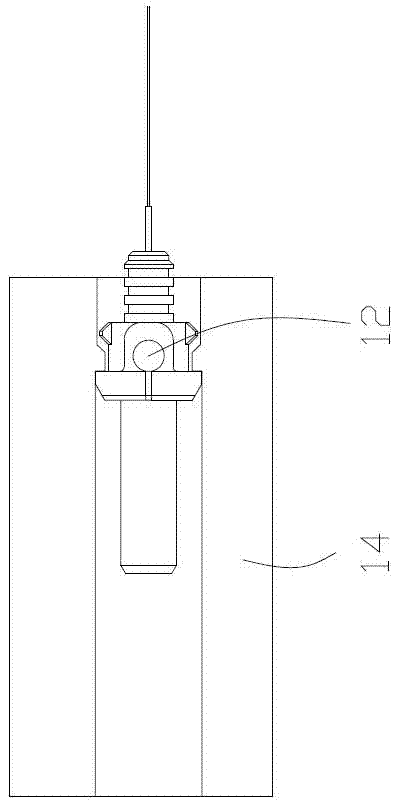

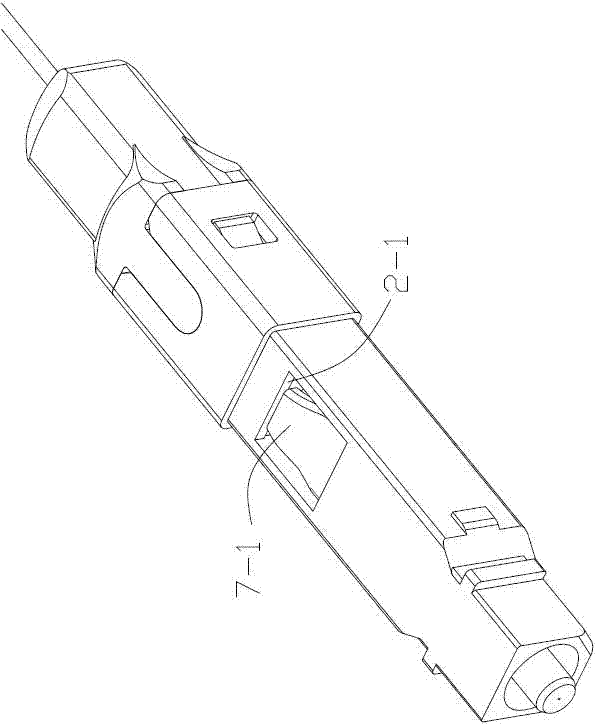

[0013] With reference to the drawings, the structure includes a jacket 1, a front bracket 2, a pin body 3, an extension sleeve 4, a preset optical fiber 5, a heat shrinkable protective sleeve 6, a connecting bracket 7, a spring 8, a reed 9, and an optical fiber clamp 10. , The back seat 11, the second fusion splice core 12, the first fusion splice core 13, the optical fiber clamp 14, wherein the preset optical fiber 5 and the pin body 3 are connected together by glue to form the second fusion splice core 12. The second fusion splice core 12 and the extension sleeve 4 are combined with the first fusion splice core 13, the second fusion splice core 12 and the first fusion splice core 13 are placed in the fiber clamp 14, the rear seat 11, and the connection bracket 7 And the heat-shrinkable protective sleeve 6 are successively penetrated into the user end optical fiber.

[0014] A spring 8, an optical fiber clamp 10 and a reed 9 are attached to the connecting bracket 7, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com