Hot-melt field-assembled optical fiber connector

A fiber optic connector and on-site assembly technology, which is applied in the coupling of optical waveguides, etc., can solve the problems of increased cost of on-site termination, low assembly efficiency, and large communication loss of connectors, so as to save on-site assembly time and increase the success rate of assembly , the effect of reducing the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

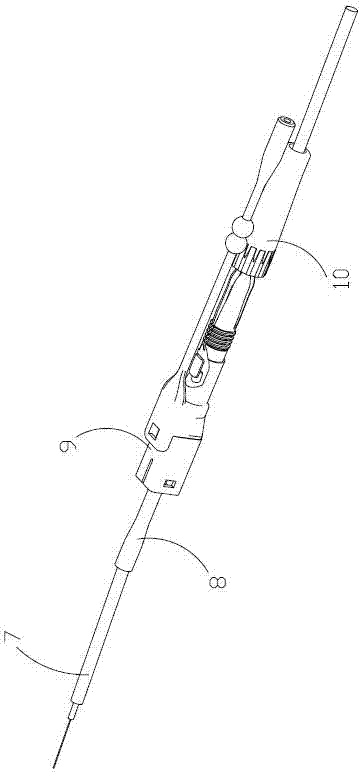

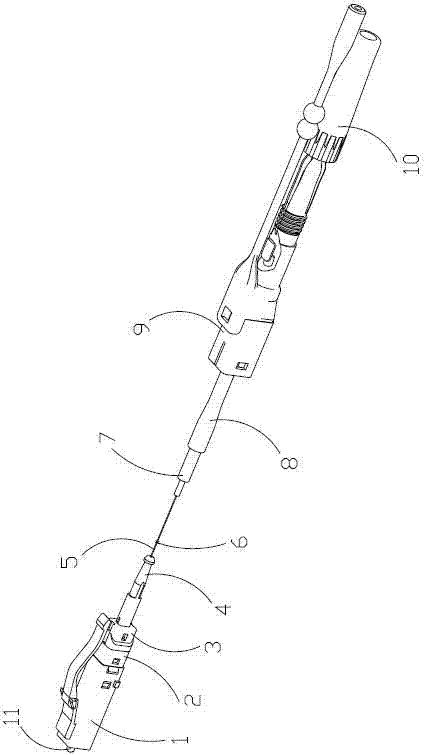

[0019] 1) First thread the screwed back seat 10, the rear bracket assembly 9, and the heat-shrinkable protection tube 8 into the user-end optical fiber 7 in sequence, and use a special tool and an optical fiber cutter to cut the user-end optical fiber 7 to a fixed length to prepare the user-end optical cable. Such as figure 1 shown.

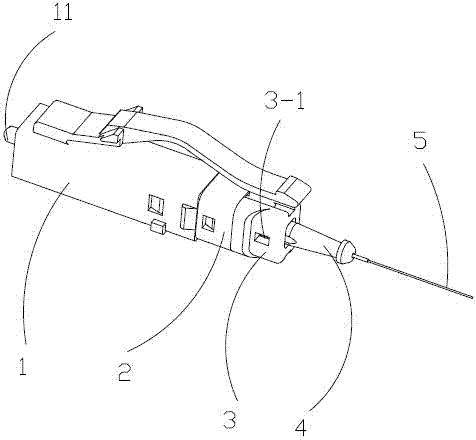

[0020] 2) The optical fiber protection part 4 is clamped in the prefabricated hole of the connecting bracket 2 through its limit card point, and the prefabricated optical fiber 5 is cut to a fixed length with an optical fiber cutter, as shown in figure 2 shown.

[0021] 3) Use an optical fiber fusion splicer to fuse the prepared prefabricated optical fiber and the user-end optical fiber to generate a fusion point 6, pull out the optical fiber protection member 4, and insert the limit card point into the limit hole of the ferrule 3, thereby starting to protect the prefabricated optical fiber 5, such as image 3 shown.

[0022] 4) Put the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com