Production method of 90íÒelbow steel skeleton of composite tube and dedicated die therefor

A steel frame and composite pipe technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, forming tools, etc., can solve the problem that the thickness of the plastic layer on the inner and outer walls of the steel frame is not easy to meet the standard requirements, and the manufacturing cost of the 90° elbow is high. The overall strength decline and other problems, to achieve the effect of guaranteed strength, small spherical error, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

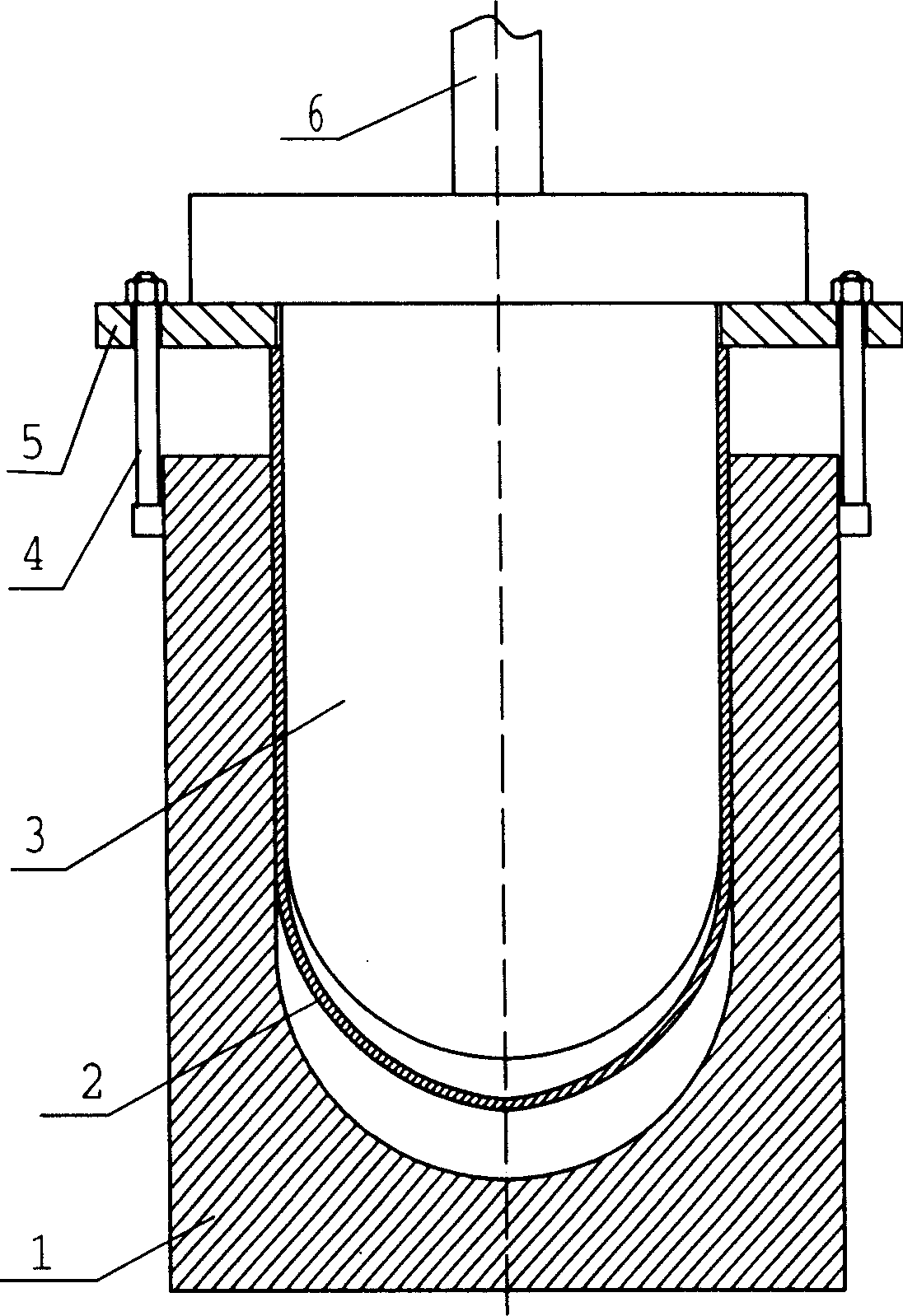

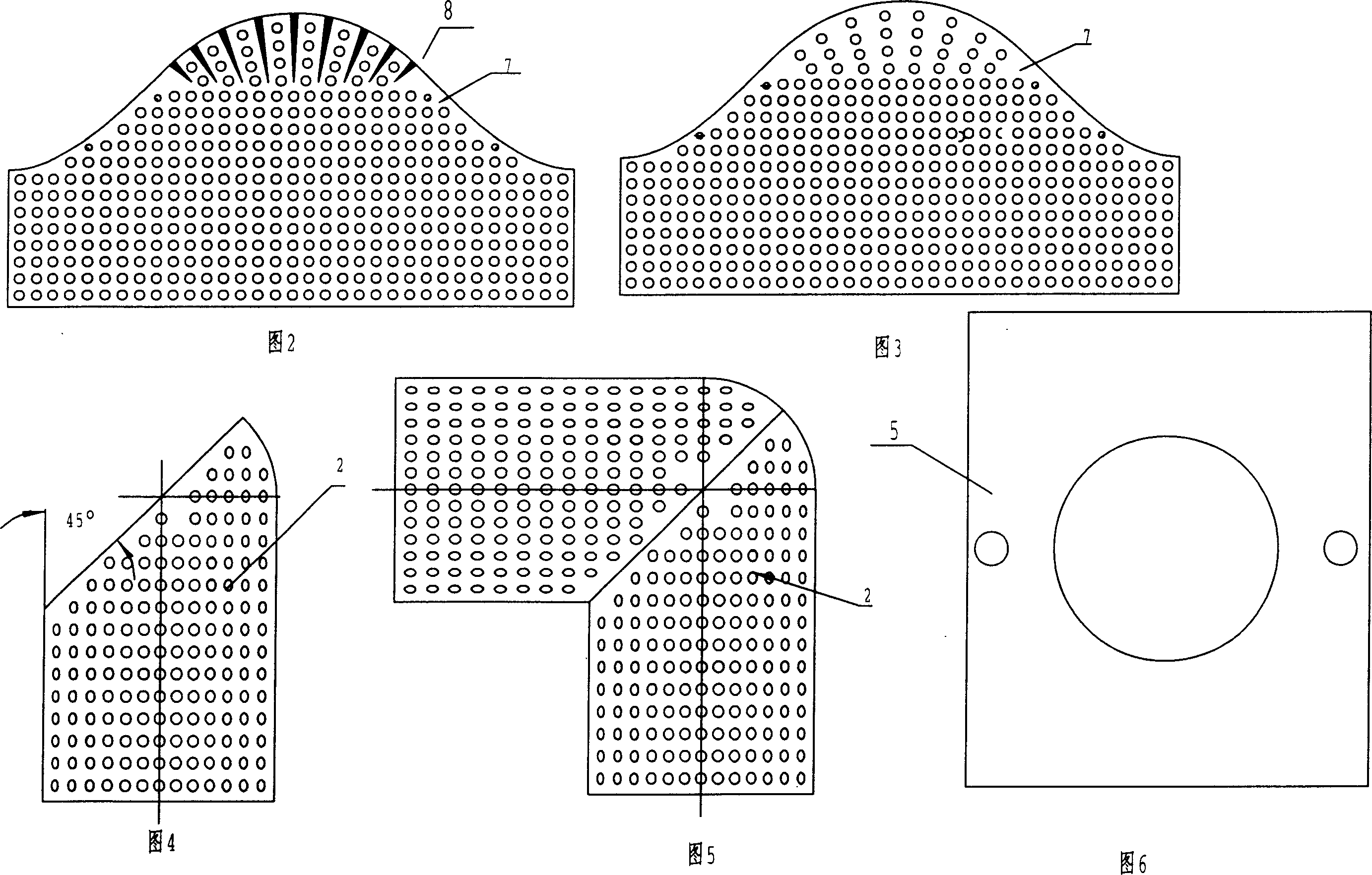

[0017] refer to figure 1 ~Figure 6, the processing method of the composite pipe 90° elbow steel skeleton is as follows:

[0018] Cut the steel plate into the shape of the coiled plate 7 according to the drawing, and punch or drill holes. The holes are to be used for plastic casting and make the inner and outer walls form a complete whole. Roll the coiled plate 7 into a cylindrical shape and butt weld it, put it into the die 1, and then insert the punch 3 into the steel skeleton 2 that has been made. The hydraulic press or an oil cylinder is connected with the pressure rod 6, pushes the punch 3, presses the steel frame 2 into the die 1 through the punch 3 and the pushing plate 5, the protruding part of the steel frame 2 is spherically formed with the concave-convex die, and the steel The cylindrical portion of the skeleton 2 is also corrected with the insertion of the punch 3 . After the punch 3 is pressed to the end, the punch can be extracted. Because the steel skeleton 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com