Novel PSA (pressure swing adsorption) oxygen generator

An oxygen generator and a new type of technology, applied in the field of medical equipment, can solve the problems of unsightly overall appearance, many pipeline welding points, large welding residual stress, etc., and achieve fast and convenient switching, simple pipeline, and less welding residual stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

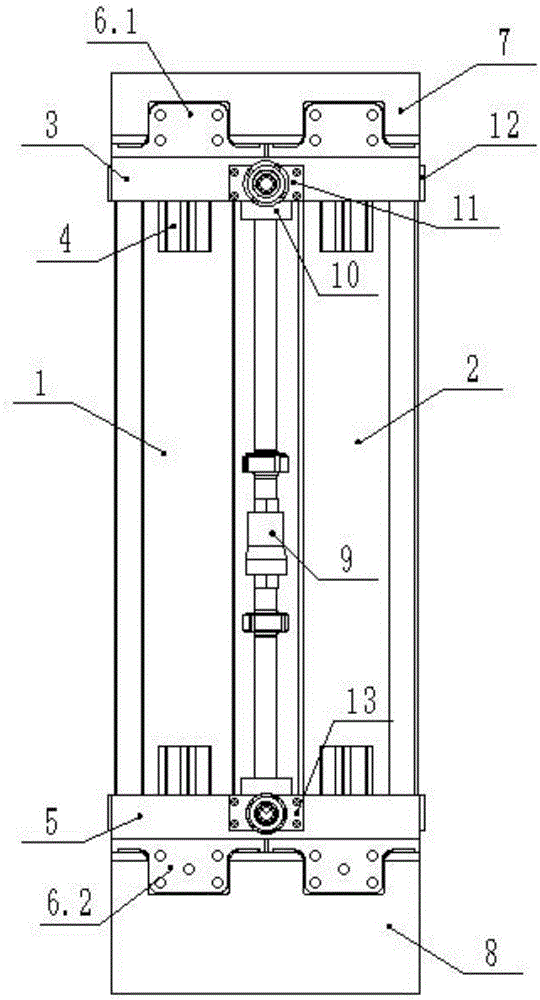

[0044] Such as Figure 1~4 As shown, a novel PSA oxygen generator provided by the present invention includes a first adsorption separator module 1 , a second adsorption separator module 2 , an air seat, a gas collecting pipe and a cylinder 4 .

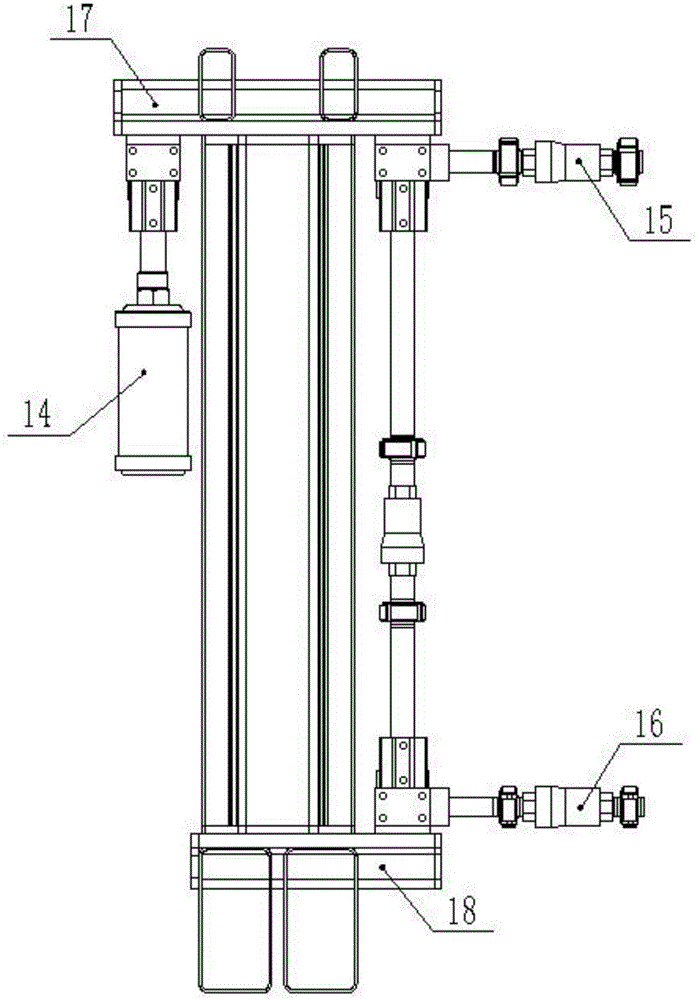

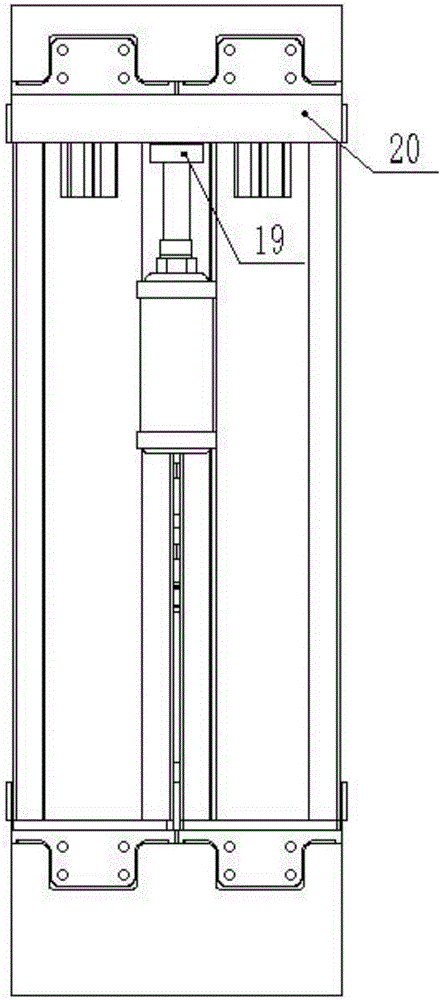

[0045] The air seat includes an upper air intake seat 3 , an upper air outlet seat 20 and a lower air outlet seat 5 , and the air collector includes an upper air collector 17 and a lower air collector 18 .

[0046] The middle of the upper air collecting pipe 17 is provided with a first air collecting through hole, the middle of the side of the upper air collecting pipe 17 is provided with a first installation opening, and both ends of the side are provided with a first air port. Both the mouth and the first gas port communicate with the first gas-collecting through hole.

[0047] The middle of the lower air collecting pipe 18 is provided with a second air collecting through hole, the middle of the side of the lower air collecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com