Effective alternating-current motor stator winding preparation method

A technology of AC motor and stator winding, which is applied in the direction of electric components, manufacturing motor generators, electrical components, etc. It can solve the problems of unbalanced resistance value of three-phase windings, easy formation of circulating current in three-phase windings, and welding of coils, etc., to achieve coil Good winding process, saving welding materials and reducing the effect of welding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

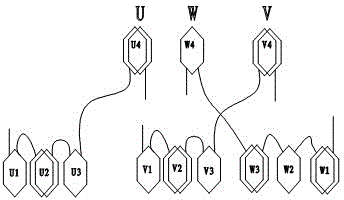

[0027] The following is an example of a 36-slot three-phase four-pole cross winding.

[0028] A method for preparing a high-efficiency AC motor stator winding, including winding, threading, and wire embedding processes.

[0029] The winding process is: each phase U, V, W has six coils U1, U2, U3, U4, V1, V2, V3, V4, W1, W2, W3, W4, wherein each phase has six coils wound continuously After winding, the coils have the same winding direction, and there are no joints between the 6 coils of each phase; among them, W1, W3, V2, V4, U2, and U4 all include 2 large coils, and the span of the large coils is 1 to 9 slots. W2 , W4, V1, V3, U1, and U3 are all a small coil with a span of 1 to 8 slots.

[0030] The threading process is after the winding process and before the embedding process. The function of the threading process is to make the winding direction of the large coil and the small coil of each phase opposite. The threading process includes:

[0031] (1) Place the wound coils...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com